Observe Safety Guidelines TROUBLESHOOTING GUIDE

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely,

contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

1-800-833-9353.

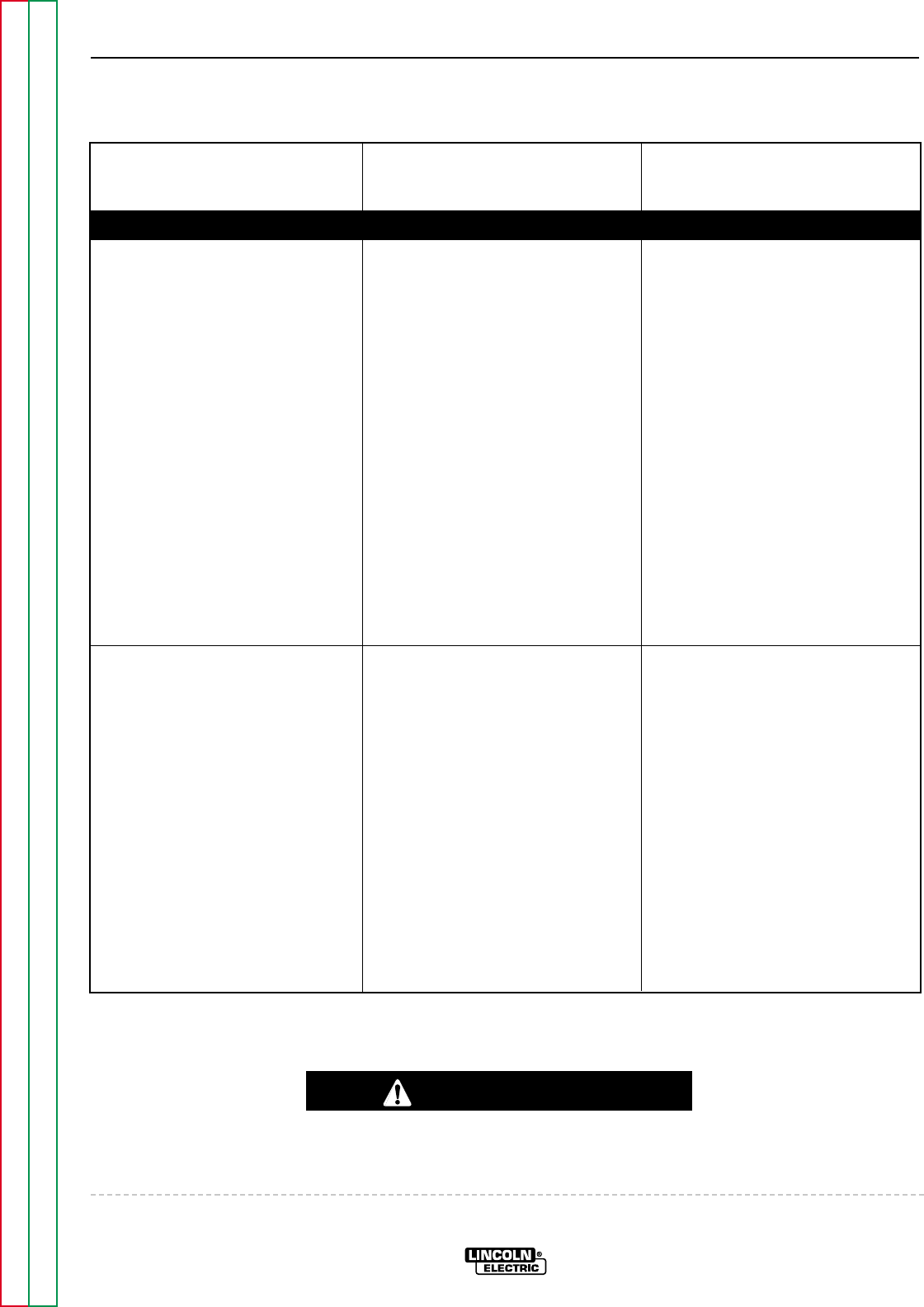

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

ENGINE PROBLEMS

The engine shuts down shortly

after starting.

1. Check for adequate fuel supply.

2. If any indicator light is lit when

the engine shuts down, that par-

ticular system has faulted.

Check system.

3. Check the battery cables for

loose or faulty connections.

1. Check the RUN/STOP switch

and associated leads for loose

or faulty connections.

2. Perform the Shutdown

Solenoid Test.

3. The Peripheral PC board may

be faulty. With the RUN/STOP

switch in the "RUN" position, the

Peripheral PC board should nor-

mally supply 10VDC to the shut-

down solenoid via leads #224

and #262. See the Wiring

Diagram.

4. See the Engine Starting Diag-

nostic Chart.

The engine will not idle down to low

speed. The machine has normal

weld output and auxiliary power.

1. Make sure the IDLER switch is

in the "AUTO" position.

2. Make sure there is NOT an

external load on the weld termi-

nals nor the auxiliary power

receptacles.

3. Check for mechanical restric-

tions in the solenoid linkage.

1. Perform the Idler Solenoid

Test.

2. Check leads #227, #232L,

#232M and #226A for loose or

faulty connections. See the

Wiring Diagram.

3. The Pull Coil PC board may be

faulty.

F-10 F-10

TROUBLESHOOTING & REPAIR

COMMANDER 500

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC