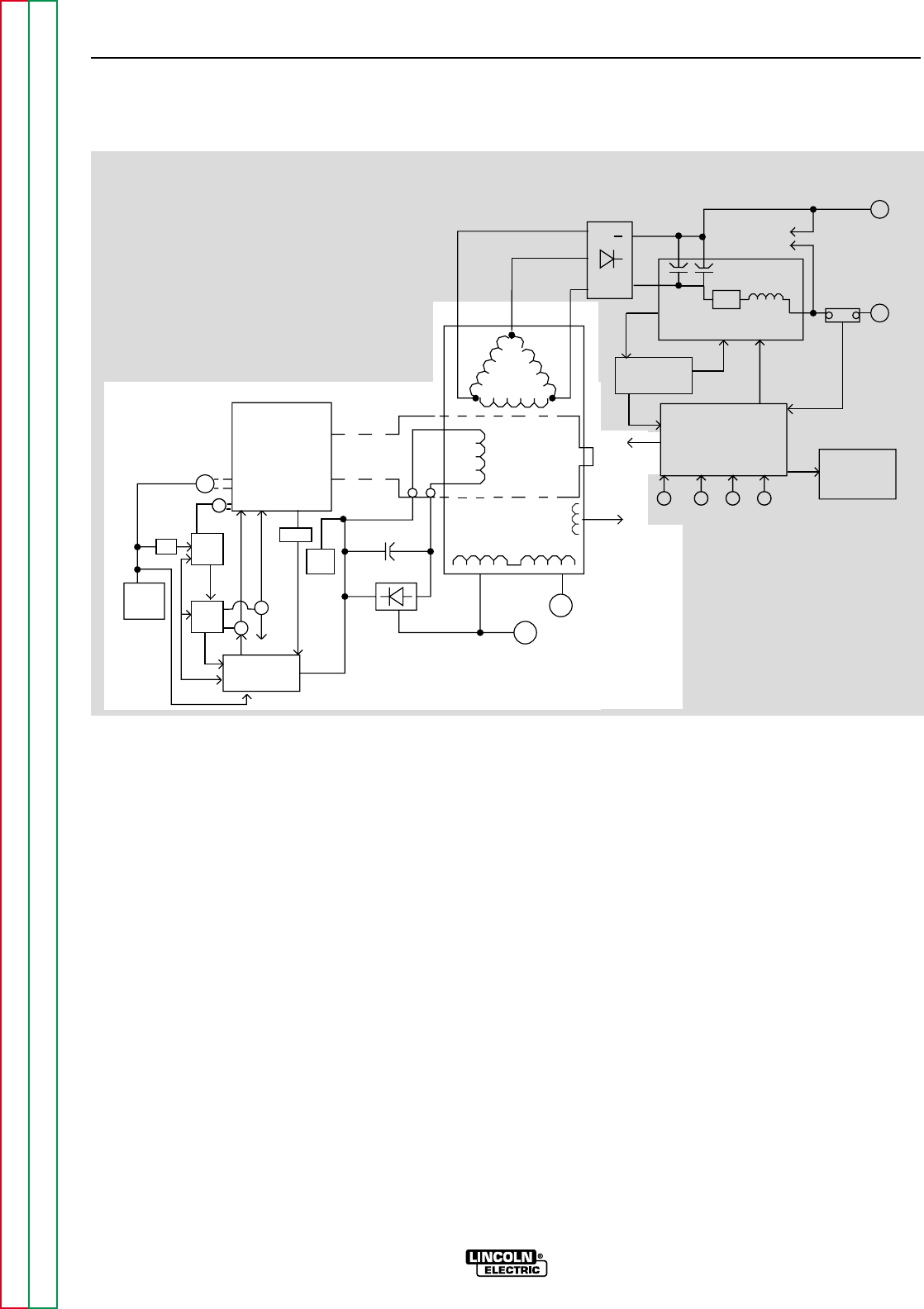

GENERAL DESCRIPTION

The Commander 500 is a diesel engine-driven welding

power source capable of producing 500 amps at

40VDC at a 100% duty cycle. The engine is coupled to

a brush-type alternating current generator. This AC

output is rectified and controlled by Chopper

Technology to produce DC current for multi-purpose

welding applications. The Commander 500 is also

capable of producing 12,000 watts of AC auxiliary

power at 100% duty cycle.

BATTERY, ENGINE, ROTOR,

STATOR, PULL COIL BOARD AND

PERIPHERAL BOARD – ENGINE

PROTECTION

The 12VDC battery powers the engine starter motor

and also supplies power to the Battery PC board, Pull

Coil PC board, Peripheral PC board and associated

circuitry. When the engine, which is mechanically cou-

pled to the rotor, is started and running, the 12 VDC

battery voltage is fed through the Battery PC board to

the rotor field coil via a brush and slip ring configura-

tion. This excitation or "flashing" voltage magnetizes

the rotor lamination. This rotating magnet induces a

voltage in the stationary windings of the main alterna-

tor stator. The stator houses a three-phase weld wind-

ing, a 120/240VAC single-phase auxiliary winding, and

a 42VAC wire feeder power winding.

The engine alternator supplies charging current for the

battery circuit. The Peripheral board monitors the

engine sensors and will shut the engine off in the event

of low oil pressure, engine over temperature, malfunc-

tion of the engine’s alternator system or a low fuel con-

dition. The idler solenoid is mechanically connected to

the engine’s throttle linkage. If no welding or auxiliary

current is being drawn from the Commander 500, the

Pull Coil board activates the idler solenoid, which then

brings the engine to a low idle state. When output cur-

rent is sensed, either weld or auxiliary, the Weld

Control PC board deactivates the idler solenoid, and

the engine returns to high RPM.

E-2 E-2

THEORY OF OPERATION

COMMANDER 500

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

ENGINE ROTOR

STATOR

AUXILIARY WINDINGS

W

E

L

D

W

I

N

D

I

N

G

MECHANICAL

ROTATION

STARTER

ALTERNATOR

ENGINE

SENSORS

OUTPUT PROCESS/RANGE

1

2

0

V

A

C

120VAC

RECEPTACLES (2)

240VAC

RECEPTACLE

SLIP

RINGS

ANALOG

POWER SUPPLY

BOARD

ARC

WELD

CONTROL

BOARD

CONTROL

CONTROL SELECTOR

PWM

SIGNALS (2)

VOLTMETER

AMMETER

BATTERY

S

H

U

T

D

O

W

N

I

D

L

E

R

PERIPHERAL

BOARD

BATTERY

BOARD

PULL

COIL

BOARD

SOL

SOL

TO

IDLE

HOLD

COIL

42 VAC TO 14 PIN AMPHENOL

THREE-PHASE

RECTIFIER

CHOKE

IGBT

WORK

TERMINAL

ELECTRODE

TERMINAL

+

+

SHUNT

F

E

E

D

B

A

C

K

__

POWER MODULES

(2)

TO WELD

CONTROL

BOARD

FOR WIRE FEEDER

COMMANDER 500

(2) (2)

80 VDC

(2)

20 VDC

THERMAL

LIGHT

TO WELD

CONTROL

BOARD

10

VDC

10

VDC

120

VDC

1/2

BATTERY

BD

RUN/STOP

SWITCH

FIGURE E.2 - BATTERY, ENGINE, ROTOR, STATOR, PULL COIL BOARD

AND PERIPHERAL BOARD – ENGINE PROTECTION

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.