SPI9000 Inverter Unit FI9 – FI14 User Manual

MN04004002E

For more information visit: www.EatonElectrical.com 3-17

September 2006

Cable Installation and the UL Standards

To meet the UL (Underwriters Laboratories) regulations, a UL approved copper cable with a

minimum heat-resistance of +60/75°C must be used.

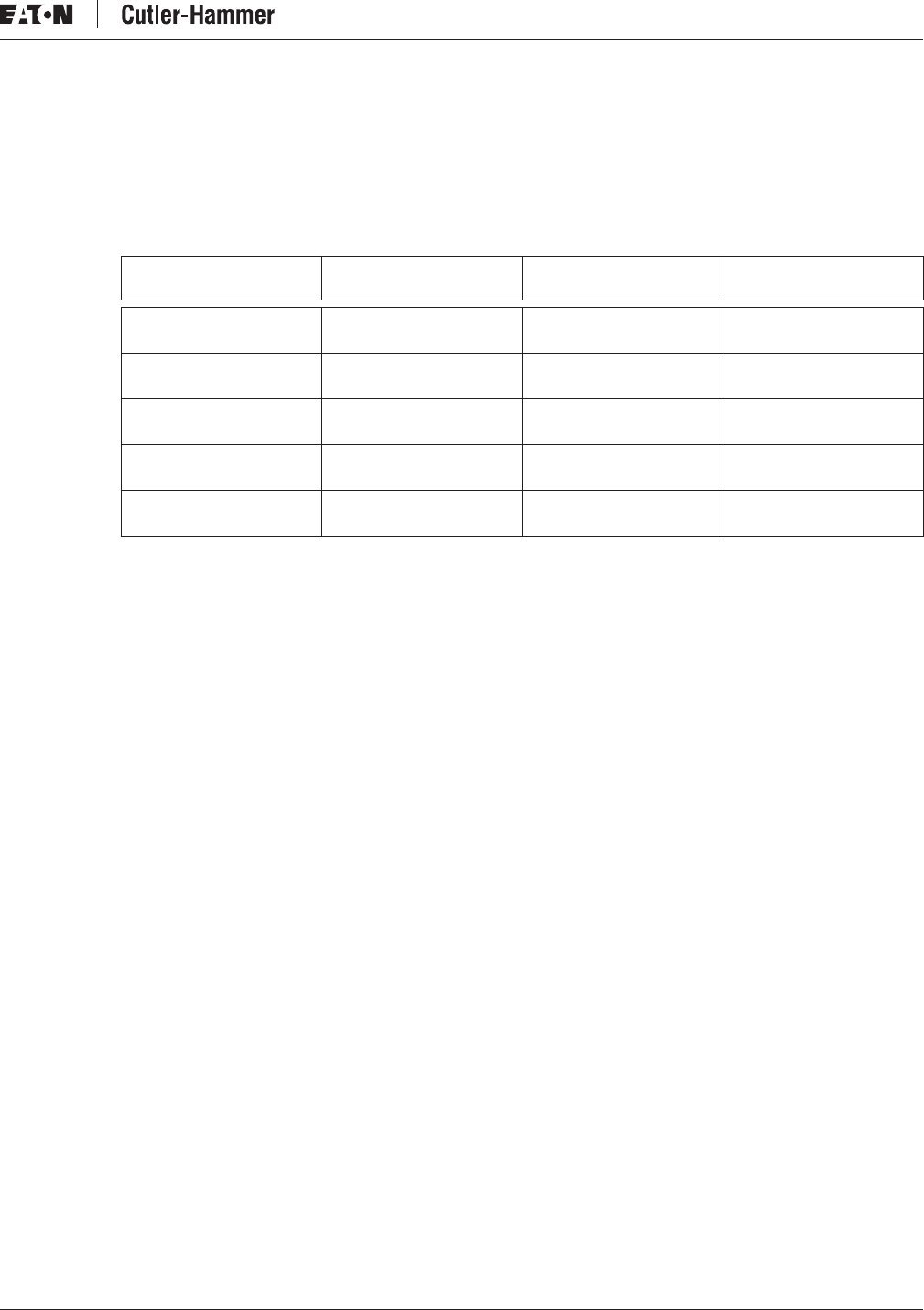

The tightening torques of the terminals are given below in Table 3-9.

Table 3-9: Terminal Tightening Torques

ᕃ

Tightening torque of terminal connection to the isolative base.

Note: Apply counter torque to the nut on the other side of the terminal when tightening/

loosening the terminal screw in order to avoid damage to the terminal.

Cable and Motor Insulation Checks

1. Motor cable insulation checks

Disconnect the motor cable from terminals U, V and W of the inverter and from the

motor. Measure the insulation resistance of the motor cable between each phase

conductor as well as between each phase conductor and the protective ground

conductor.

The insulation resistance must be >1MΩ.

2. DC supply cable insulation checks

Disconnect the DC supply cable from terminals B- and B+ of the inverter and from DC

supply. Measure the insulation resistance between each conductor and ground.

The insulation resistance must be >1MΩ.

3. Motor insulation checks

Disconnect the motor cable from the motor and open the bridging connections in the

motor connection box. Measure the insulation resistance of each motor winding. The

measurement voltage must equal at least the motor nominal voltage but not exceed

1,000V.

The insulation resistance must be >1MΩ.

Nominal Current Voltage Frame

Tightening Torque in

in-lb (Nm)

ᕃ

140 – 245

100 – 170

380 – 500V

525 – 690V

FI9 340 (40)

300 – 460

208 – 325

380 – 500V

525 – 690V

FI10 340 (40)

520 – 920

385 – 650

380 – 500V

525 – 690V

FI12 340 (40)

1030 – 1300

920 – 1030

380 – 500V

525 – 690V

FI13 340 (40)

1600 – 2300

1300 – 1900

380 – 500V

525 – 690V

FI14 340 (40)