SPI9000 Inverter Unit FI9 – FI14 User Manual

MN04004002E

For more information visit: www.EatonElectrical.com A-1

September 2006

Appendix A — Fault Codes

When a fault is detected by the inverter control electronics, the drive is stopped and the

symbol F together with the ordinal number of the fault, the fault code and a short fault

description appear on the display. The fault can be reset with the RESET button on the

control keypad or via the I/O terminal. The faults are stored in the Fault History Menu M5,

which can be browsed. Table A-1 contains all the fault codes.

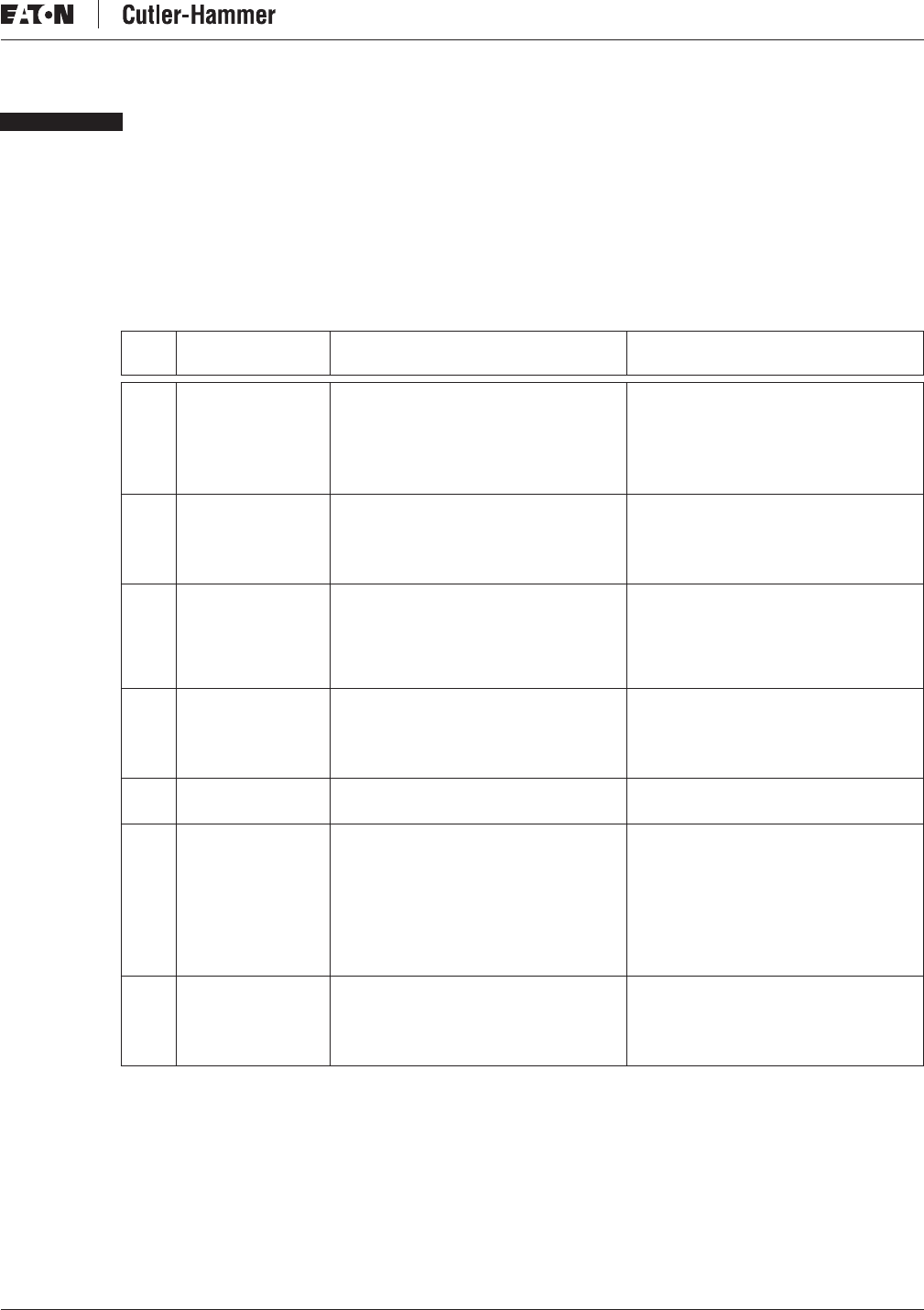

Table A-1: Fault Codes

ᕃ

Programmable.

Fault

Code Fault Possible Cause Solution

1 Overcurrent Inverter detected too high a current

(>4 x I

n

) in the motor cable:

• Sudden heavy load increase

• Short circuit in the motor

• Unsuitable motor

Check loading.

Check motor.

Check cables.

2 Overvoltage The DC link voltage exceeded the

defined limits:

• Deceleration time too short

• High overvoltage spikes in supply

Set the deceleration time longer.

Add a brake chopper or brake

resistor.

3 Ground Fault

ᕃ

Current measurement has detected

that the sum of motor phase currents

is not zero.

• Insulation failure in cables or

motor

Check motor cable and motor.

5 Charging Switch Charging switch is open, when the

START command is given:

• Faulty operation

• Component failure

Reset the fault and restart.

Should the fault re-occur, contact

your Cutler-Hammer distributor.

6 Emergency Stop Stop signal was given from the

option board.

7 Saturation Trip Various causes:

• Component failure

• Brake resistor is short circuited or

overloaded

Cannot be reset from the keypad.

Switch off the power.

DO NOT RE-CONNECT POWER.

Contact Eaton.

If this fault appears simultaneously

with Fault 1, check motor cables and

motor.

8 System Fault • Component failure

• Faulty operation

Note: See exceptional fault data

record on Page 5-12.

Reset the fault and restart.

Should the fault re-occur, contact

your Cutler-Hammer distributor.