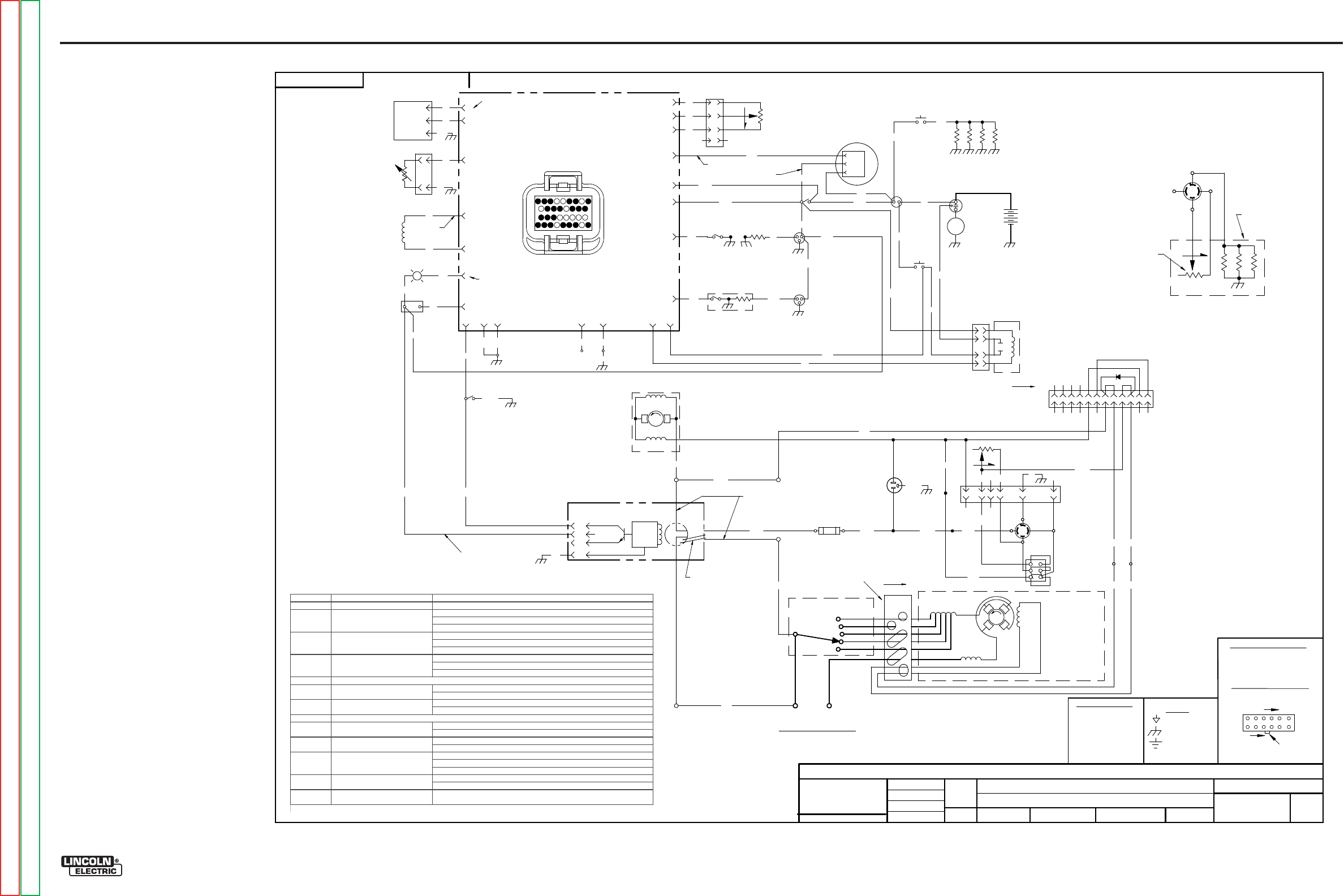

ELECTRICAL DIAGRAMS

G-9

PIPELINER® 200

SCHEMATIC - COMPLETE MACHINE - CODE 11471 - (L13350)

L13350

PIP

EL

INE

R 200

D K

UBOTA

MA

C

HI

NE SC

HE

MATI

C

NONE

L12362

DO NOT

SCAL

E

T

HIS DR

A

WING

EQU

IPM

ENT

TYPE

:

SUB

JECT

:

NA

CRM

37569

1

PAG

E

___

OF

___

1

EN

GIN

E

ERIN

G CON

T

RO

LL

ED

M

ANUF

AC

T

URER:

No

T

HIS

DOCUM

EN

T

CON

T

AIN

S

PR

O

PRI

ET

ARY IN

FO

RMA

T

ION

OW

NE

D BY

L

INCO

L

N G

LOBAL

, INC.

AN

D MAY N

OT

B

E D

UP

L

ICA

T

ED,

COMMUNIC

AT

ED

T

O

OT

HE

R P

AR

T

IES

OR U

S

ED

FO

R A

NY PUR

POS

E

WIT

HOU

TT

HE

EXPR

ES

S

W

RI

TT

EN

P

ERMI

S

SI

ON

OF

L

INCO

L

N G

LOBAL

, INC.

PROP

RI

ETARY

&

CO

NFI

DENT

IAL:

Ne

w

t

MATE

RIA

L

TOLERA

NC

E

("

") T

O

A

GR

EE

WI

T

H PU

B

LI

SHE

D S

TA

ND

A

RD

S.

ON

AL

L

A

NG

LE

S I

S ± .

5

O

F

A D

E

GR

EE

ON

3

PLACE DECIMALS IS

±

.0

02

in

.(

±

0.05

mm)

ON

2

PLAC

E D

E

CIM

AL

S I

S ± .

0

2 i

n. (

±

0.

5

mm)

UN

LESS

OT

HE

RW

ISE

SPE

CIF

IE

DTO

LE

RA

N

CE

:

MA

NU

FACT

URING

TOLERA

NC

E

PE

R E

2056

CHANGE

DET

AIL:

REFERENCE:

SC

ALE:

MAT

ER

IAL

DI

SPOSITI

ON:

AP

PR

OVAL

DA

TE:

PR

OJ

EC

T

NUMB

ER

:

DOCUMENT

NUMBER:

DOCUMENT

REVISION:

UNIT

S:

IF PRINTED

@A2SIZE

INCH

11/16/2007

Ma

gli

etta

D.

B

END

ER

-

DRAW

N

B

Y:

ENG

IN

EE

R:

CL

EVEL

AND

APPROVE

D:

CONTRO

L:

A

L13350

EA

RT

H GROUND

FR

AME GROUND

C

OMMO

N

LABELS:

E

X. 12

PIN CONNECTOR

LAT

CH

127

6

2

1

VI

E

W OF CONNECTOR ON PC BO

ARD

CONNE

CT

OR PIN N

UM

BERS:

RESIS

TO

R: O

HM

S/WA

TTS

CAPAC

ITO

R:

MF

D/V

OLT

S

C

OM

PONE

NT

VALUE UN

IT

S:

B-BLACK OR GRAY

G-G

REEN

R-RED OR PINK

U-BLUE

W-WH

IT

E

Y-YE

LLO

W

N-BROWN

L

EAD C

OL

ORCODE:

K924-5 REMOTE CONTROL

(OPTIONAL)

RHEOSTAT

RE

MOT

E CO

NT

R

OL

BOX

2

5+/-1.

25

OH

M

S

E

ACH

6

4+/-6.

4

OH

M

S

MAX

CCW

Y

W

G

X

RE

MOT

ECO

NT

R

OL

PLUG

OIL

PRESSUR

E

S

WITC

H / S

ENDER

TE

MPER

AT

UR

E

S

WITC

H

TE

MPER

AT

URE

GAUGE

S

I

G

OIL

PRESSURE

GAUGE

SI

G

A

MM

ET

ER

+

-

1

EN

GI

NE

PR

OT

E

CTIO

N

LIG

HT

A

LT

ERN

AT

OR

WK

G

TY

PI

CA

L C

URRE

NT

DRA

W I

S

40

AMPS

+

HOU

R M

ET

ER

S

WITC

H C

LOSES

AT

6+/-2

P

SI

SENDE

R

OPER

ATI

O

N:

0

P

SI ->

10

+/-5 O

HM

S

40

P

SI ->

10

5+/-5

O

HM

S

80

P

SI ->

18

7+/-5

O

HM

S

SENSO

R

GROUND

S

LEAD

O

N

SENS

E

OF

WE

LD

OR

AU

XI

LI

AR

Y

LOAD

S

WITC

H C

LOSES

AT

11

0v

+/3

vC

SENDE

R

OPER

ATI

O

N:

90

v

C -> 5

1.2+/-4.

3 O

HM

S

COLO

R: R

ED

12

VO

LT

NO

RM

A

LL

Y

OFF

SHOW

N IN "OFF"

PO

SITI

ON

53

51

C

50

50

A

51

51

A

21

2D

43

20

0

54

44

21

2A

21

2B

61

84

4A

84

1

84

4

-40 T

O 4

0

AMPS

A

MM

ET

E

R

SHOW

S F

UL

L

DI

SCHARG

E

W

HIL

E

PRES

SI

NG

GLO

W

P

LU

G

S

WITC

H

40

AM

P / 1

2

VO

LT

IG

B

L

GLO

W

P

LU

GS

12.6

VO

LT

S

MIN

AT

RE

ST

14-

14.5

VO

LT

S

W

HIL

E

RUN

NIN

G

LOC

AT

E

D

BE

HIND U

PPE

R L

EFT

PO

RTIO

N

OF C

O

NTR

O

L

PANEL

1

2

3

W

AT

ER

TE

M

P.

SENSOR

EN

GI

NE

SPEED

SENSOR

31

60F

19

58

6

IG

NITIO

N

S

WITC

H

21

2C

12

ST

A

RT

B

UTTO

N

7

52

A

52

B

55

62

ST

A

RT

ER

RELAY

RELA

Y

CO

NT

A

CT

S F

O

R 5

2

AN

D 5

2

A

AR

E

NO

RM

A

LL

Y

OPE

N. TH

E

ST

A

RT

E

R M

OT

O

R C

A

N

O

NL

Y

B

E

ENGAGED

WHE

N TH

E I

G

NITIO

N

S

WITC

H I

S "

O

N"

AN

D TH

E

ECU

SENSE

S

LES

S T

HA

N 7

00

RP

M.

IF

TH

E

EN

GI

N

E I

S

SH

UT

DOW

N D

U

E T

O

A F

A

ULT

(EV

EN

IF T

HA

TCO

ND

ITION

DOES NOT

RESU

LT INA FLA

SH

CO

DE

,

SU

CH

AS

RUNN

ING

OUT OF F

UE

L),

TH

E I

G

NITIO

N

S

WITC

H

WI

LL

NEE

D TO

BE

TUR

NE

D

OFF TH

E

N

BAC

K

O

N TO

RE

ST

A

RT TH

E

EN

GI

N

E.

4

87

86

88

11

2

3

10,0

00 +/- 1,0

00

O

HM

S

MAX

TUR

N

P

OT C

OU

NT

ER

CL

OCK

WI

S

E T

O

REDUC

E

RE

SI

ST

ANC

E

AN

D

SUBSEQUE

NTL

Y

REDUC

E

RP

M

B

Y

U

P T

O 1

50

RPM

R

AT

E

D

VO

LT

AG

E:

12

V

R

AT

E

D C

URRE

NT: 22m

A

MAX

60

SE

NSO

R OPE

RATION:

-4

v

F

-> 1

8.

8

0 kOHMS

104v

F ->

1.

1

4 kOHMS

212v

F ->

.

1

6 kOHMS

57 34

RATE

D VOLTAGE: 1

2V

RATE

D

CUR

RE

NT: 2A

COIL RESISTE

N

CE:

2.8

+/- .

2

8 OHMS AT 2

0vC

EN

ERGIZE

D FOR

RUN

DE

-E

NE

RGIZE

D FOR STOP

ACT

UATO

RCO

NT

ROLS RP

M

ME

C

HA

NI

CAL STOP WI

L

L SHUT

DOWN TH

E ENGI

NE AT 11

5%

OF RATE

D SP

EE

D.

27

28

84

1A

9

21

2E

26

64

16

15

51

B

70

A

70

B

CONNE

CT TO

GROUN

D FO

R

80

0R

PM

CONNE

CT TO

GROUN

D FO

R

1600

RP

M, L

EAVE

UNCONNE

CT

ED

FO

R 1

80

0R

PM

30

32

60

E

A

CTU

AT

OR

56 18

6913

60

A

94 20

9317

CCW

RP

M C

O

NTR

O

L

P

OT

E

NTIOM

ET

ER

WI

RE

-TIE

D TO

HARNESS

BE

HIND C

O

NTR

O

L

PANEL

OPE

N L

EA

D I

S

WI

RE

-TIE

D IN

SI

D

E T

HE

HARNES

S

BE

HIND C

O

NTR

O

L

PANEL

SHOW

N IN "

A

UT

O

IDL

E

" P

O

SITI

ON

IDL

E

R

S

WITC

H

GN

D-

B

84

1B

LIGHTCODE FAILUREDETECTED POSSIBLECAUSE-CORRECTIVEMEASURE

LONG1, SHORT 1 RPMIS OVER 115% OF RATED RPM(2070 RPM) ACTUATOR IS STUCK -REMOVE ACTUATORAND VERIFYPLUNGERPULLS INWHEN ENERGIZED

LOW OIL - CHECK OIL LEVELON DIPSTICK

FAULTYOIL PRESSURE SWITCH -CHECK THAT"WK" STUD IS OPENWHENENGINE IS RUNNING

LEAD TOOIL PRESSURE SWITCH "WK" STUD MAYBEGROUNDED - CHECK

BROKEN OR LOOSEBELT - INSPECT

LEAD TO"L" TERMINAL ON ALTERNATORMAY BESHORTED TO GROUND - CHECK

FAULTY ALTERNATOR- CHECK

AMOUNT OR QUALITY OFCOOLANTINCORRECT -CHECK

FAULTYWATER TEMPERATURE SWITCH - CHECK THAT"WK" STUD ISOPEN WHENENGINE IS NOTRUNNING

LEAD TOWATER TEMPERATURE SWITCH MAY BEGROUNDED - CHECK

LONG1, SHORT5

FAULTYRPMSENSOR - CHECKFORGOOD CONNECTION

FAULTYECU -CHECK FOR12VOLTS ONSUPPLY LEAD TO RPM SENSORFROMECU

FAULTYACTUATOR-CHECKFOR PROPERCOIL RESISTANCE

LEADS TOACTUATORMAY BEOPEN OR GROUNDED - CHECK

LONG 2, SHORT3

FAULTYWATER TEMPERATURE SENSO

R-CHECK FORPROPER RESISTANCE

LEAD TOWATER TEMPERATURE SENSORMAYBEOPEN - CHECKFORCONTINUITY

FAULTYWATER TEMPERATURE SENSOR -CHECK FORPROPER RESISTANCE

LEAD TOWATER TEMPERATURE SENSORMAYBEGROUNDED -CHECK

LEAD TO"L" TERMINAL ON ALTERNATORMAY BEOPEN - CHECKFOR CONTINUITY

BROKEN OR LOOSEBELT - INSPECT

FAULTYALTERNATOR-CHECK

INCORRECTBATTERY-INSPECT

FAULTYALTERNATOR-CHECK

LONG2, SHORT8

LESS THAN4VOLTS TORPMSENSOR AND/OR

ACTUATORSENSED BYECU FAULTYECU -CHECK FOR12 VOLTS ON LEADS TORPM SENSORAND ACTUATOR FROM ECU

NOT ENABLED FOR LINCOLNPRODUCTS

NOT ENABLED FOR LINCOLNPRODUCTS

0 RPMIS DETECTED AND 12VIS DETECTED

FROM"L" TERMINAL ONALTERNATOR

LONG2, SHORT1

LONG1, SHORT4

HIGH WATER TEMPERATURE DETECTED FOR 1

SECOND

LONG1, SHORT 2 LOW OILPRESSURE DETECTED FOR 1 SECOND

LONG1, SHORT3

"L" TERMINALIS GROUNDED ON ALTERNATOR

FOR 1 SECOND

LONG2, SHORT 7 OVER18 VOLTS DETECTED FROMALTERNATOR

CURRENT TO ACTUATOR IS OUT OF LIMITLO

NG 2, SHORT 2

LONG2, SHORT6

0 VOLTS DETECTED FROM"L" TERMINAL ON

ALTERNATOR FOR1SECOND

LONG2, SHORT 5 150C WATER TEMPERATUREDETECTED

-50CWATER TEMPERATURE DETECTEDLONG 2, SHORT4

1

2 VO

LT SUP

PLY

GLO

W

P

LU

G

B

UTTO

N

+

B

ATT

ERY

ST

A

RT

ER

MOT

OR

ST

A

RT

ER

SOLEN

OI

D

BRUS

H

PO

SITI

O

N

SHOW

N

AS

VI

EWE

D FR

OM

CO

NTR

O

L

PANEL

D

C

AU

XI

LI

ARY

RECE

PT

A

CL

E

NEG

ATI

V

E

O

UT

P

UT TE

RMIN

AL

PO

SITI

V

E

O

UT

P

UT TE

RMIN

AL

J3-4

J3-1

J3-3

J3-2

SE

RI

E

S FI

E

LD

SHU

NT FIE

LD

-

+

GEN

ER

ATOR LEAD BLOC

K

SHOWN A

S VIEWED WITH

ENGI

NE I

N THIS

DI

RE

CTION

-

-

+

+

INT

ERPOLE

C

OIL

S

SHU

NT

FIE

LD

SE

RI

E

S FI

E

LD

12 11 10

9

8

7

65

4

3

2

1

P

10

J5

FJW-

5A

R C

OIL

P

AI

R:

22.5

+/-.5 O

HM

S

EACH

FL

YBAC

K

DI

OD

E

PREVE

NT

S

VO

LT

AG

E

S

PI

KE

S I

N

SHU

NT FIE

LD

FR

OM

DAMA

GI

N

G L

OCA

L/R

E

MOT

E

TO

GGL

E

S

WITC

H

WHE

N

S

WITC

HED

FD

W-

5M

EX

CIT

E

R C

OIL:

SHU

NT C

OIL

WI

N

DIN

G

S

AR

E

65

+/-1.5

O

HM

S

EACH

SE

RI

E

S

C

OIL

WI

N

DIN

G

S

AR

E .

14

3 +/-.00

5 O

HM

S

EACH

SHOW

N IN L

OCAL

PO

SITI

ON

Y

RHEO

STAT

W

G

X

RE

MOT

E

RECE

PT

A

CL

E

LOCA

L / R

E

MOT

E

S

WITC

H

15

AMP

P9

J8

45631 2

64

+/-6.4

O

HM

S

MAX

FU

SE

BRUS

H

PO

SITI

ON

SHOW

N

A

SVI

EWED

FR

OM

CO

NTR

O

L

PANEL

+

_

N

U

67

A

60

2B

72

0A

72

0C

60

2

73

0B

SELE

CT

O

R

S

WITC

H

90-MI

N

13

0-8

0

19

0-1

20

24

0-1

60

22

0-M

AX

WELDING

GENERATOR

DC EXCITER

CCW

JUM

PE

R

P

LU

G I

S

WI

RE

-TIE

D U

P

BE

HIN

D

LOCA

L / R

E

MOT

E

S

WITC

H

O

N RI

G

HT

SI

D

E

OF M

AC

HIN

E

D

C

EX

CIT

E

R U

SE

S

RE

SI

DUAL

MAGN

ETI

S

M TO FL

ASH

TY

PI

CA

L O

C

V (

WA

RM M

AC

HIN

E

):

88-9

8

VO

LT

S

AT M

A

X

RHEO

STAT

47-6

0

VO

LT

S

AT MI

N R

HEO

STAT

D

RI

VER

CIR

C

UIT

S

JUM

PE

R

P

LU

G I

S

WI

RE

-TIE

D U

P

BE

HIN

D

LOCA

L / R

E

MOT

E

S

WITC

H

O

N RI

G

HT

SI

D

E

OF M

AC

HIN

E (

AS

VI

EWE

D FR

OM

CO

NTR

O

L

PANE

L)

THES

E LEADS M

UST BE

RO

UTE

D TH

RU

CUR

RE

NT SE

NSO

R IN SA

ME (

CUR

RE

NT

FLO

W) DIRE

CTION AS S

HOWN

67

B

61

0D

61

0C

61

0B

61

0

84

2

3

TU

R

NS

73

0A

72

0B

N

U

60

2A

42

41

GN

D-T

70

C

84

1B

BAC

K,

B

OTT

OM

OF M

AC

HIN

E

FRO

NT , RIG

HT

SI

DE

OF

EN

GI

NE

FRO

NT, L

EFT

SI

D

E

OF

EN

GI

NE

B

AC

K,

L

EFT

SI

D

E

OF

EN

GI

NE

JUM

PE

R

P

LU

G I

S

BE

HIN

D L

OWER

RI

G

HT

SI

D

E

OF C

O

NTR

O

L

PANEL

LO

WE

R L

EFT

OF

CO

NTR

O

L

PANEL

LO

WE

R L

EFT

OF

CO

NTR

O

L

PANEL

CE

NT

E

R

OF

CO

NTR

O

L

PANEL

B

AC

K,

RI

G

HT

SI

D

E

OF

EN

GI

NE

B

AC

K,

L

EFT

SI

D

E

OF

EN

GI

NE

B

AC

K,

RI

G

HT

SI

D

E

OF

EN

GI

NE

CE

NT

E

R

OF

CO

NTR

O

L

PANEL

UN

DE

R L

EFT D

OOR

LO

WE

R RI

G

HT OF C

O

NTR

O

L

PANEL

LO

WE

R L

EFT

OF C

O

NTR

O

L

PANEL

ENGINE CONTROL UNIT (ECU)

LOC

AT

E

D

BE

HIND U

PPE

R

PO

RTIO

N

OF C

O

NTR

O

L

PANEL

R

AT

E

D

VO

LT

AG

E: 1

2V

R

AT

E

D C

URRE

NT: 4.5

A

(M

A

X.)-T

E

RMIN

A

L

#

15

LEAKAG

E

CURRE

NT 10m

icro

A (

MA

X.)-T

E

RMIN

A

L

#

16

1

2 VO

LT SUP

PLY

THE E

C

U WIL

L

INDI

CATE FA

ULT CON

DITIONS BY FLASHING

THE E

NGI

NE P

ROTE

CTION LIGHT IN A CO

DE

D SEQ

UE

N

CE,

SEE

C

HA

RT FOR FA

ULT COD

ES A

N

DCO

R

RE

CTIVE ME

AS

U

RE

S.

WHEN T

HE E

NGI

NE IS S

H

UT DOWN

D

UE TO A FAULT,

THE IGNITION SWITCH WIL

L NEED TO BE TU

R

NE

D OFF

THE

N BA

CK O

N TO RESTA

RT THE E

NGI

NE.

EC

U C

ONNE

CT

O

R D

ET

AI

L

9

17

25

34

26

18

10

1

1

2 VO

LT

SU

PPLY

THE P10 P

LUG IS ONLY

ON U

NITS WITHOUT

THE WIRE FEE

D MO

D

ULE. THE WIRE FEED

MO

D

ULE HA

S A HA

R

NE

SS THAT PLUGS

DI

RE

CTLY

INTO J5.

FLASHES ALTER

NATO

R

SE

NSES ALTERNATO

R O

UTP

UT

SCHEM

ATI

C

S

2597

3

CURREN

T

SENSING PC BOARD

B

AC

K,

L

EFT

SI

DE

OF

EN

GI

NE

TE

MPER

AT

URE

SENSOR

G-9

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC