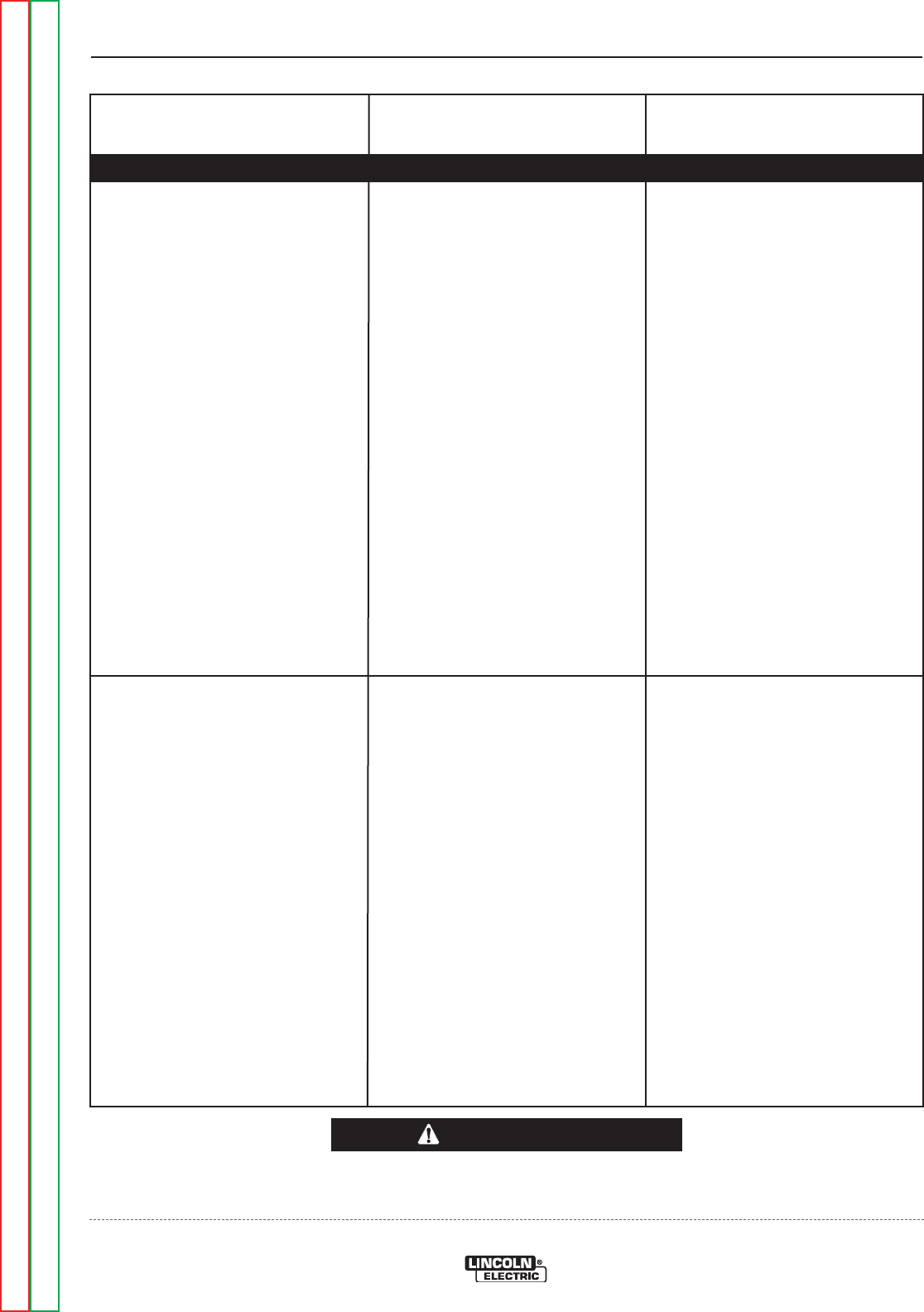

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely,

contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed.

Call 1-888-935-3877.

CAUTION

1. Check the welding cables for

loose or faulty connections.

2. The welding cables may be

excessively long or coiled.

3. Check the main DC generator

brushes for good commutation

and alignment. Contact the

Lincoln Electric Service Dept. 1-

888-935-3877.

1. The engine RPM may be low.

If necessary perform the

Engine Throttle Adjustment

Test. (PERKINS code 10929

ONLY)

2. Perform the DC Exciter Test.

3. Check the fine current control

field rheostat for resistance

and proper operation. Normal

resistance is 64 ohms. Check

associated wires for loose or

faulty connections. See the

Wiring Diagram.

4. Check the current range

selector switch and contacts

for proper operation.

5. Perform the Main Generator

Shunt Field Winding Test.

6. The main armature may be

faulty. Check for grounds.

The actual welding current is

much greater than is indicated

on the dials.

1. The engine operating speed

may be too high. If necessary

perform the Engine Throttle

Adjustment Test. (PERKINS

code 10929 ONLY)

2. While the machine is loaded,

check the series coils for signs

of “arcing.” This condition

could point to shorted turns in

the series coils.

3. Perform the DC Exciter Test.

1. Check the main DC generator

brushes for good commutation

and alignment. Contact the

Lincoln Electric Service Dept.

1-888-935-3877.

F-6 F-6

PIPELINER® 200

PROBLEMS

(SYMPTOMS)

The actual welding current is

much less than is indicated on

the dials.

TROUBLESHOOTING & REPAIR

OUTPUT PROBLEMS

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC