GUN AND CABLE MAINTENANCE

For instructions on periodic maintenance for the weld-

ing gun and cables, refer to the manual for your specif-

ic model of welding gun. Also see IM-294.

GUN CABLE CONNECTOR

REQUIREMENTS TO PERMIT PROPER

CONNECTION TO LINCOLN LN-9 AND

LN-9F WIRE FEEDER

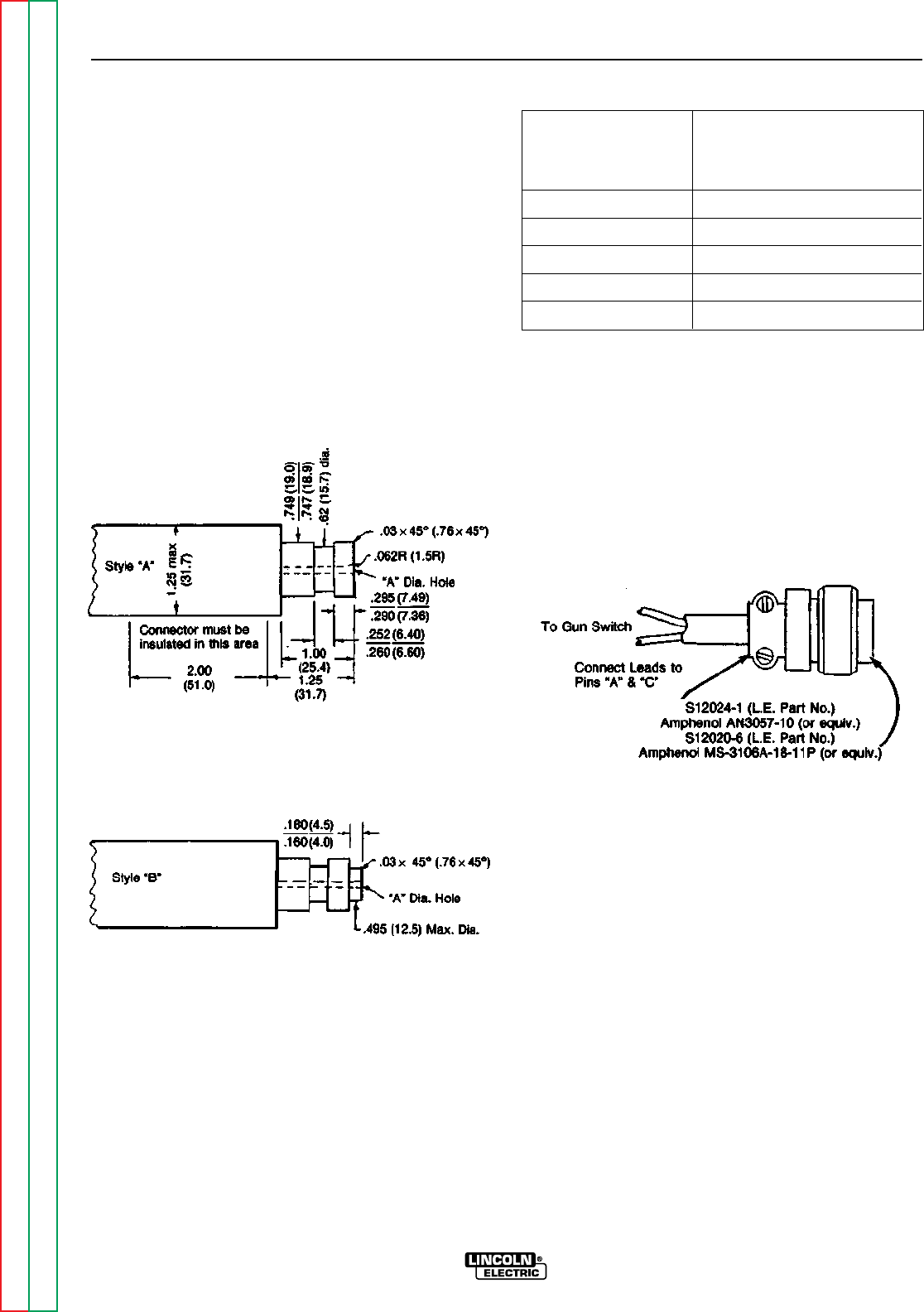

The following Figures D.1 and D.2 should serve as a

guide to determine if a particular gun or switch can be

connected to the LN-9 and LN-9F models.

“A” Diameter Hole

to be Concentric to

Wire Size .749/.747 Dia.

Within .008 F.I.M.

7/64 & .120" .152 (#24 Drill)

.068 Thru 3/32" .125 (1/8 Drill)

1/16 or .062" .078 (5/64 Drill)

.045 & .052" .062 (1/16 Drill)

.030 & .035" .055 (#54 Drill)

All dimensions in inches and (millimeters).

1/2 Amp AC 24 Volts — Inductive

1/2 Amp DC 24 Volts — Inductive

MAINTENANCE

D-3 D-3

LN-9 Wire Feeder

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

FIGURE D.1 – LN-9 CONNECTORS

LN-9 CONNECTOR FOR 1/16-120” (1.6-3.0 MM) WIRE)

FIGURE D.2 – SWITCH REQUIREMENTS

LN-9 CABLE CONNECTOR FOR .030-.052” (0.8-1.3 mm)

WIRE (FOR ALL OTHER DIMENSIONS, SEE DIAGRAM

ABOVE).

NOTE: Connector part with .7459/.747 (19.0/18.9)

diameter should be made from brass if it is to be part

of the welding current carrying circuit.