TROUBLESHOOTING & REPAIR

F-22 F-22

LN-9 Wire Feeder

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING GUIDE Observe Safety Guidelines

detailed in the beginning of this manual.

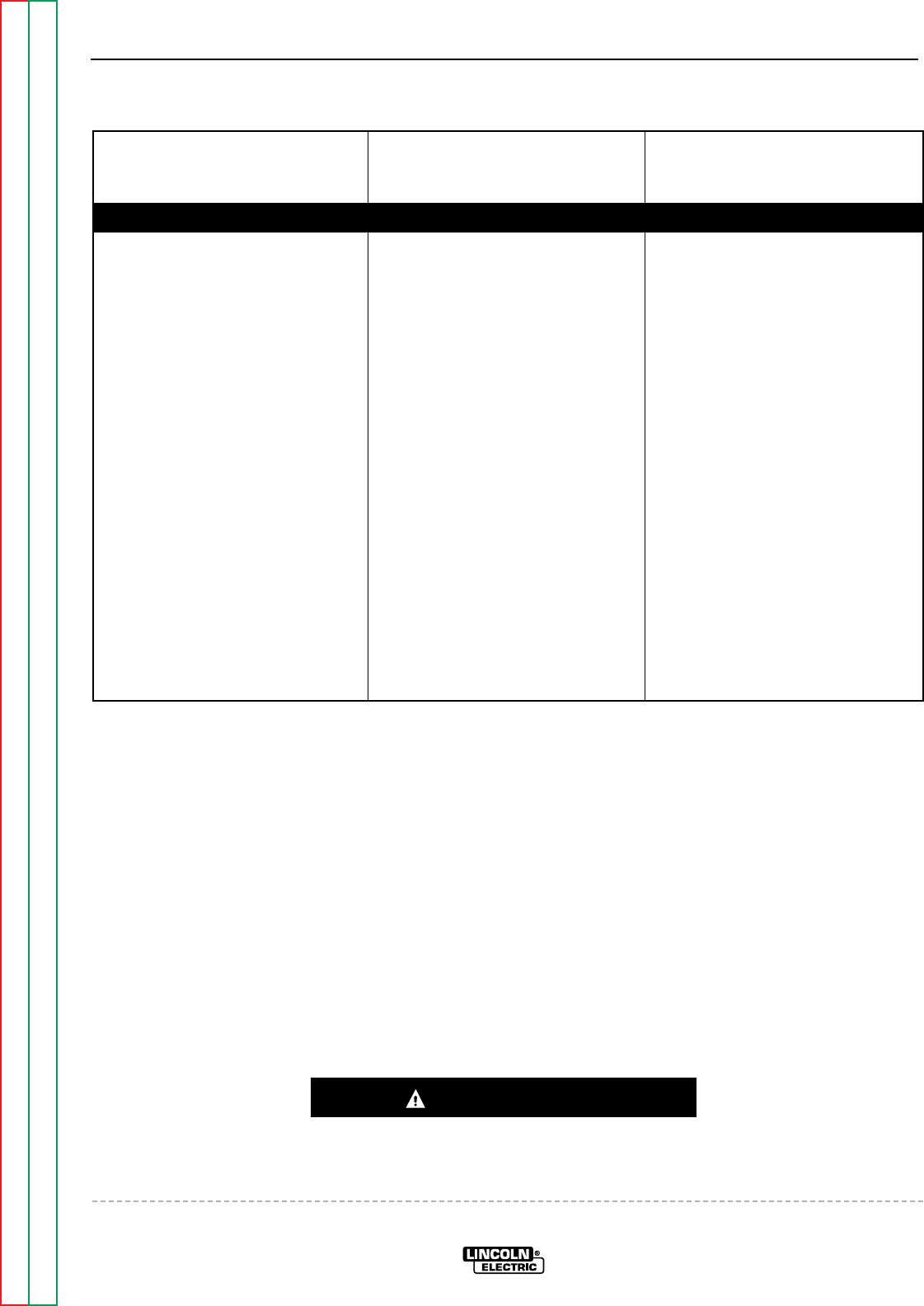

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

STARTING PROBLEMS

The arc voltage appears to rise too

slowly or stubs or blasts at the start

of a weld. Once started the weld-

ing is good.

NOTE: Pulse Power 500 operation

with a filter kit may exhibit these

symptoms.

1. Check the welding cables for

loose or faulty connections.

2. Adjust the "start" trimmer on the

voltage PC board. It should be

slightly higher than the weld

voltage.

See

Starting Charac-

teristics

in the

Operation

section

of this manual.

3. Put the Lincoln power source in

the "Machine Control" mode.

Jumper the "BYPASS" pins on

the LN-9 voltage PC board.

Adjust the weld voltage from the

power source for the process

being used. If the symptoms

persist, the power source may

be faulty.

4. Check for correct control cable

connections to the power

source.

1. If a start board is used in the

LN-9, change the jumper to

position "A." If the problem is

solved, the start board may be

faulty. Replace.

2. The voltage PC board may be

faulty. Replace.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

216-383-2531 or 1-800-833-9353.