Installation 2

Series N6700 User’s Guide 29

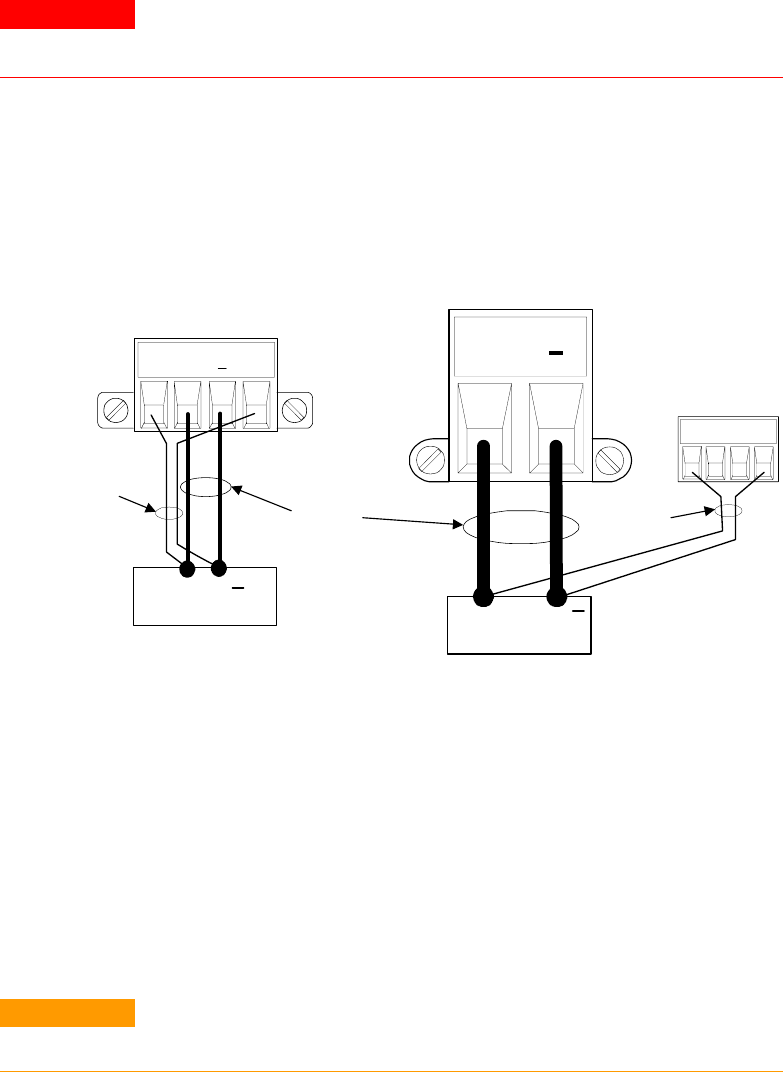

Remote Sense Connections

WARNING

SHOCK HAZARD Turn off AC power before making or changing rear panel

connections.

Remote sensing improves the voltage regulation at the load by

monitoring the voltage there instead of at the output terminals. This

allows the power system to automatically compensate for the voltage

drop in the load leads. Remote sensing is especially useful for CV

operation with load impedances that vary or have significant lead

resistance. It has no effect during CC operation. Because sensing is

independent of other power system functions, remote sensing can be

used regardless of how the power system is programmed.

Connect the unit for remote sensing by first disconnecting the straps

between sense and load terminals. Make your connections as shown

in the following figure. Connect the sense leads as close to the load as

possible. Refer to the “Wire Size” section for information about

selecting the proper wire size. Best results are obtained by using the

shortest load leads practical. It is recommended to keep load leads

under 14.7 meters (50 feet) per lead because of inductance effects.

The sense leads carry only a few milliamperes of current and can be

a lighter gauge than the load leads. However, note that any voltage

drop in the sense leads can degrade the voltage regulation of the

instrument. Try to keep the sense lead resistance less than about

0.5Ω per lead (this requires 20 AWG or heavier for a 50 foot length).

CAUTION

When remote sensing on power modules with the 50A sense connector, do not

connect the +LS and –LS terminals. These are dedicated for local sensing only.

+S + -S

TWIST

LEADS

LOAD

+

+

LOAD

+

50A SENSE

TWIST

PAIR

50 A

CONNECTOR

12A & 20 A

CONNECTOR

TWIST

PAIR

+S +LS -LS -S