WELDING CABLE CONNECTIONS

CABLE SIZE AND LENGTH

Be sure to use welding cables that are large enough.

The correct size and length becomes especially impor-

tant when you are welding at a distance from the

welder.

Table A.1 lists recommended cable sizes and lengths

for rated current and duty cycle. Length refers to the

distance from the welder to the work and back to the

welder. Cable diameters are increased for long cable

lengths to reduce voltage drops.

Lincoln Electric offers a welding accessory kit with the

properly specified welding cables. See the Acces-

sories section of this manual for more information.

INSTALLATION

A-6 A-6

RANGER 10-LX

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

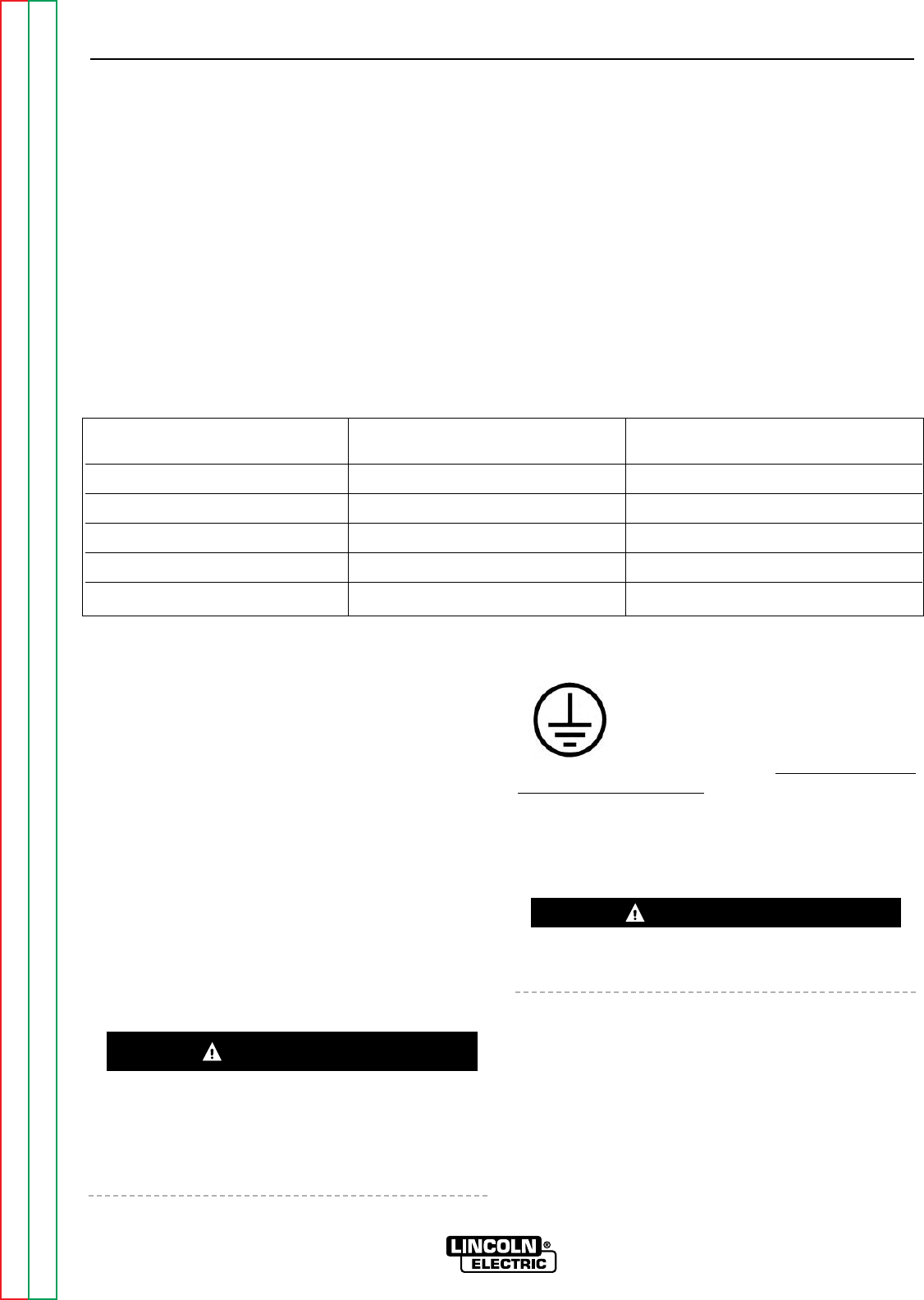

TABLE A.1 - RECOMMENDED WELDING CABLE SIZE AND LENGTH

TOTAL COMBINED LENGTH OF ELECTRODE AND WORK CABLES

Cable Size for 250 Amp Cable Size for 250 Amp

Cable Length 40% Duty Cycle 100% Duty Cycle

0-50 feet (0-15 meters) 2 AWG 1 AWG

50-100 feet (15-39 meters) 2 AWG 1 AWG

100-150 feet (30-46 meters) 1 AWG 1 AWG

150-200 feet (46-61 meters) 1 AWG 1 AWG

200-250 feet (61-76 meters) 1/0 AWG 1/0 AWG

CABLE INSTALLATION

Install the welding cables to your RANGER 10-LX as

follows. See Figure A.1 for the location of parts.

1. The diesel engine must be OFF to install welding

cables.

2. Remove the flanged nuts from the output termi-

nals.

3. Connect the electrode holder and work cables to

the weld output terminals. The terminals are iden-

tified on the case front.

4. Tighten the flanged nuts securely.

5. Be certain that the metal piece you are welding

(the “work”) is properly connected to the work

clamp and cable.

6. Check and tighten the connections periodically.

• Loose connections will cause the output terminals to

overheat. The terminals may eventually melt.

• Do not cross the welding cables at the output termi-

nal connection. Keep the cables isolated and sepa-

rate from one another.

MACHINE GROUNDING

Because the RANGER 10-LX creates

its own power from its diesel-engine

driven generator, you do not need to

connect the machine frame to an earth

ground. However, for best protection

against electrical shock, connect a heavy gauge wire

(#8 AWG or larger) from the ground stud located on

the bottom of the output panel (see Figure A.1) to a

suitable earth ground such as a metal pipe driven into

the ground.

Do not ground the machine to a pipe that carries

explosive or combustible material.

CAUTION

WARNING