Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

F-12 F-12

RANGER 10-LX

TROUBLESHOOTING & REPAIR

TROUBLESHOOTING GUIDE Observe Safety Guidelines

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

216-383-2531 or 1-800-833-9353.

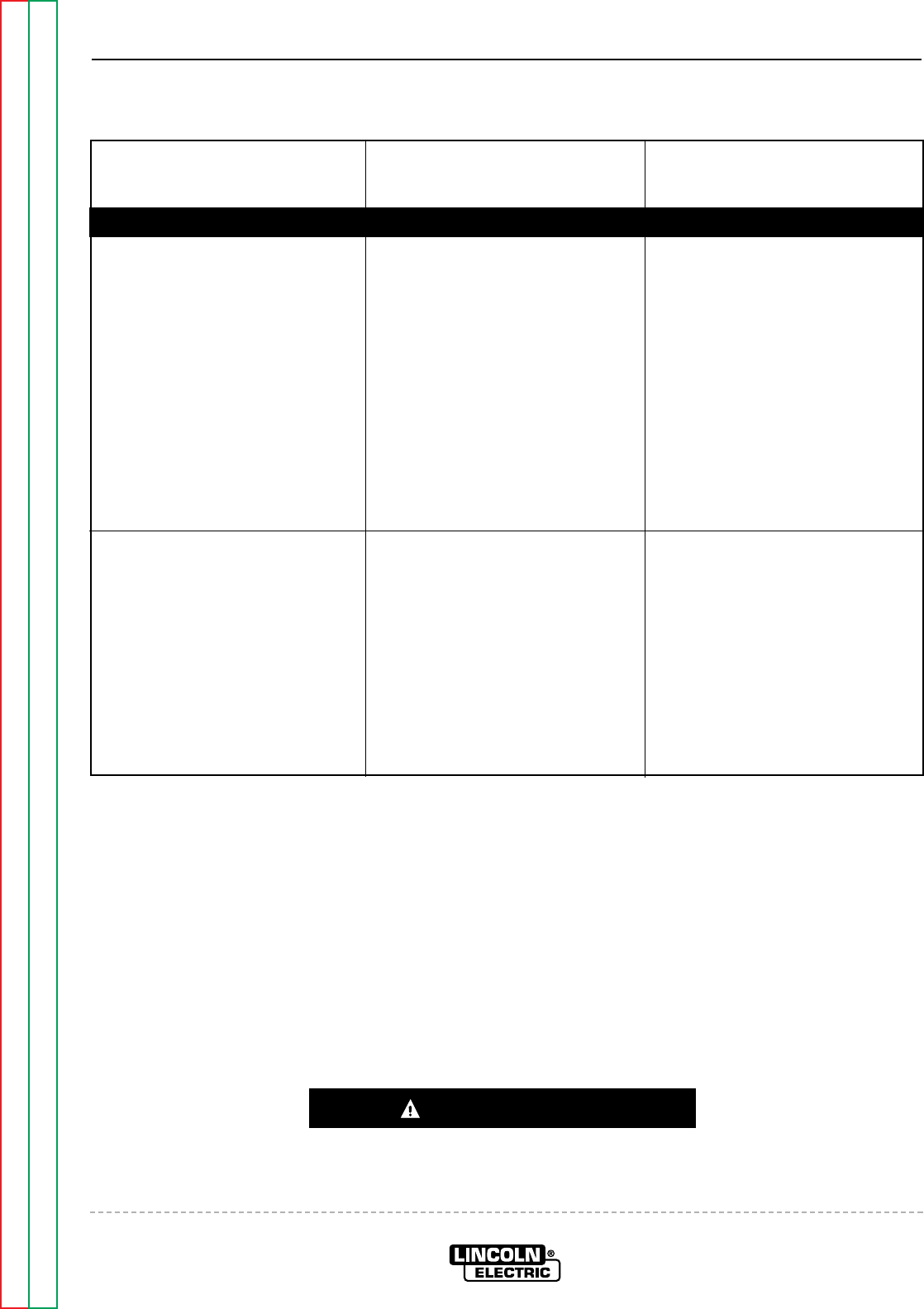

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

ENGINE PROBLEMS

The engine will not go to high idle

when attempting to weld or when

the auxiliary power is loaded.

Welding output and auxiliary power

output are normal when idler

switch is in the “HIGH” position.

1. Make sure the welding cables

and auxiliary power lead con-

nections are tight.

2. Automatic idler may not func-

tion if the auxiliary power is

loaded to less than 150 watts.

3. If using the 115/230 volt recep-

tacle for 115 volts, try using the

“other side” of the receptacle.

The internal load sensing is only

on one side of the receptacle.

1. Check for broken or faulty con-

nections in the sensing leads

(#254, 254A and lead #3).

Make sure lead #3 is looped

through the current sensor on

the control board.

2. The control board may be

faulty. Replace.

The engine will not crank or cranks

very slowly.

1. Check for loose or faulty battery

cable connections.

2. The battery may be faulty.

1. If the battery is replaced or tests

good, then the charging circuit

may be faulty. Perform the

Charging Circuit Test.

2. The starter motor or starter

solenoid may be faulty.

3. The engine may be hard to

crank due to a mechanical fail-

ure in the engine.