TROUBLESHOOTING & REPAIR

F-34 F-34

RANGER 10-LX

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

PROTECTION RELAY (CR1) TEST (continued)

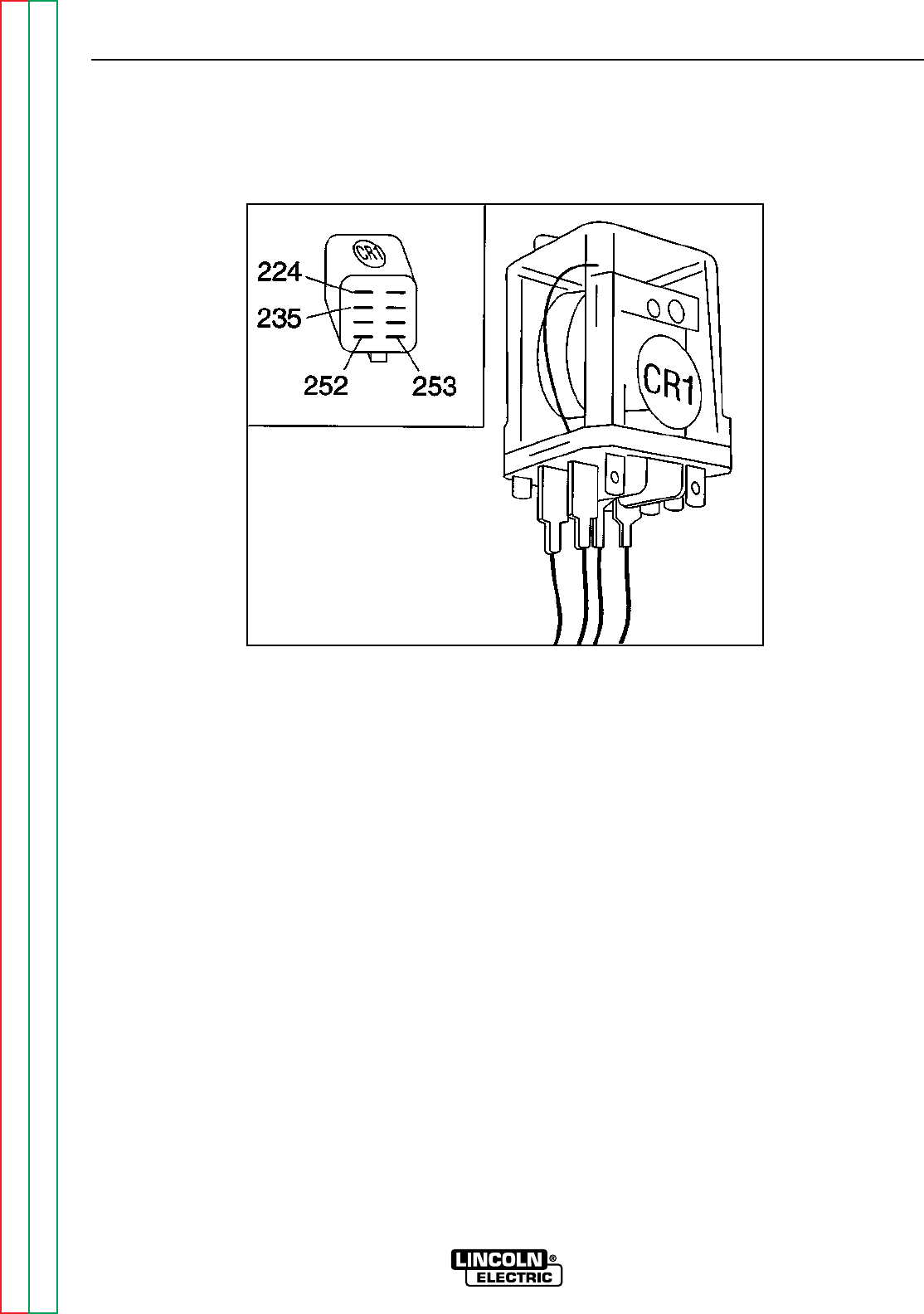

FIGURE F.7 – CR1 LEAD CONNECTIONS

TEST PROCEDURE

1. Using the 5/16” and 3/8” nut drivers,

remove the sheet metal screws from the

left case side.

2. Carefully remove the left case side.

3. Conduct this test with the engine OFF.

4. Remove leads #252, #253, #224 and #235

from relay CR1. See Figure F.7.

5. Using the 12VDC power supply, apply

12VDC to the coil terminals “A” and “B” of

the relay.

6. Check visually to see if the relay is operat-

ing when voltage is applied to the coil ter-

minals. If the relay IS operating, proceed

to step #7. If the relay is NOT operating

when coil voltage is applied, then check

the resistance of the coil. Normal coil

resistance is 100 to 150 ohms. If the relay

coil is “shorted” or “open,” the relay will

NOT operate. Replace the relay.

7. With 12VDC applied to the relay coil, use

the ohmmeter to check for continuity (zero

ohms) from terminals #4 to #7. If zero or a

very low resistance is measured, the con-

tacts are okay. If a high or infinite resis-

tance is measured, the contacts are faulty.

If NO voltage is applied to the coil termi-

nals, the resistance from #4 to #7 should

be infinite.

8. Install the left case side using the 5/16”

and 3/8” nut drivers and sheet metal

screws.