Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-28 F-28

RANGER 10-LX

AUXILIARY AND FIELD WINDING TEST (continued)

Z

W

Y

X

K

B

I

H

N

L

C

D

M

G

E

F

J

A

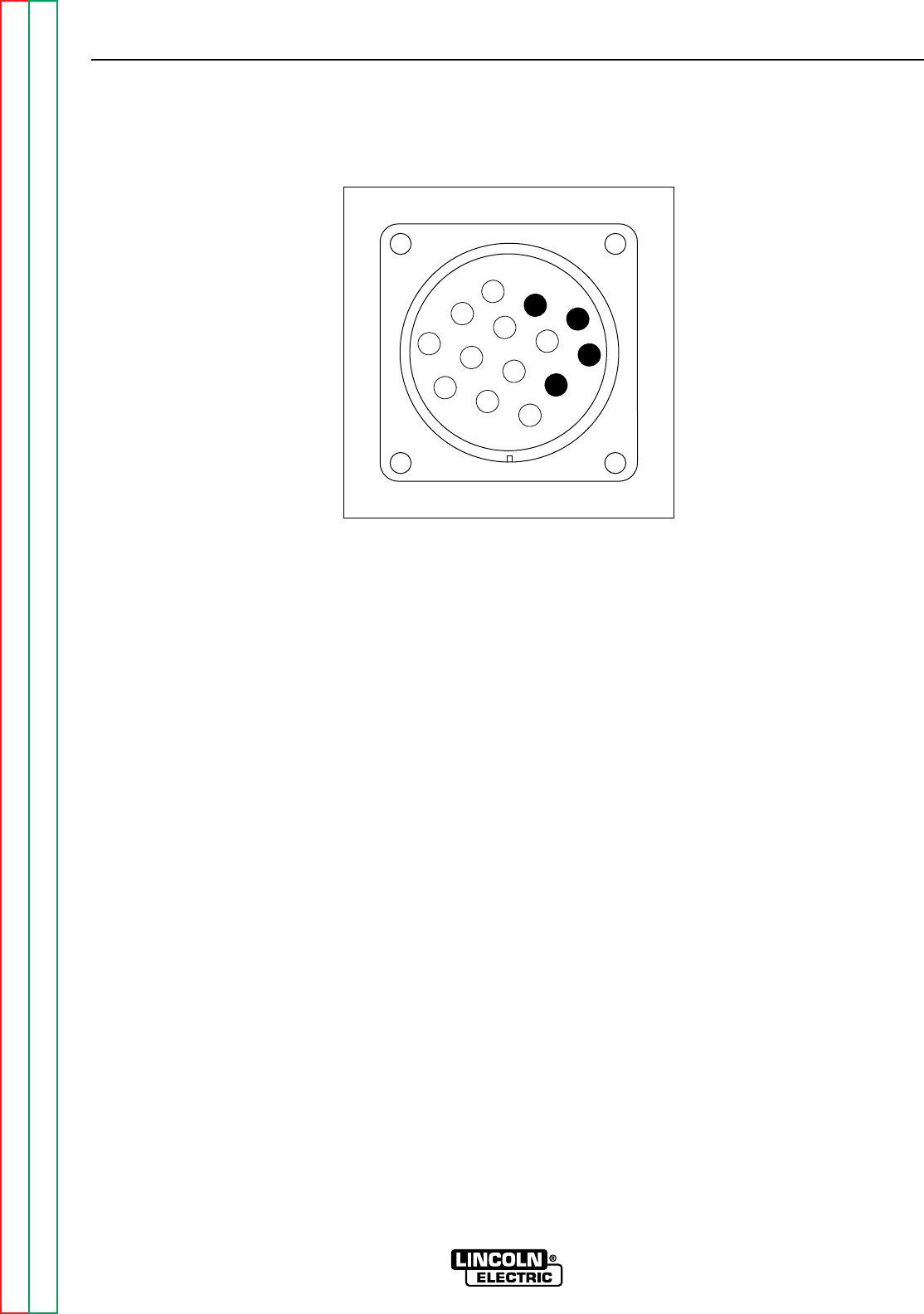

FIGURE F.4A – 14 PIN AMPHENOL PIN ASSIGNMENTS

To test the feeder winding:

1. Using the 5/16” and 1/8” nut drivers,

remove the sheet metal screws from the

right case side.

2. Carefully remove the right case side.

3. Set the voltmeter to the AC volts position.

4. Connect the voltmeter probes to leads #31

and #32 where they connect to the circuit

breaker CB2 and the 14 pin amphenol. See

the Wiring Diagram.

NOTE: It is possible to check this voltage

reading at the amphenol by inserting the test

probes at pin A (for lead #32) and pin J (for lead

#31A). See Figure F.4A. However, if you use

this method and get no voltage reading, it

could mean there is a break or loose connec-

tion in the leads between the circuit breaker

and the amphenol. Check the reading again

and with one probe at the circuit breaker con-

nection for lead #31 and the other probe at

amphenol pin A.

5. Start the engine and run it at high idle (3700

RPM).

6. Set the output control to the maximum

position (position 10).

8. Check the AC voltage reading. It should be

between 115 and 126 VAC.

9. Connect the voltmeter probes to leads #31

and #42 where they connect to the circuit

breaker CB2 and the 14 pin amphenol. See

the Wiring Diagram.

NOTE: It is possible to check this voltage

reading at the amphenol by inserting the test

probes at pin K (for lead #42) and I (for lead

#31B). See Figure 4A. However, if you use this

method and get no voltage reading, it could

mean there is a break or loose connection in

the leads between the circuit breaker and the

amphenol. Check the reading again with one

probe at the circuit breaker connection for lead

#31 and the other probe at amphenol pin K.

10. Set the output control to the maximum

position. (position 10).

11. Check the AC voltage reading. It should

be between 43 and 50 VAC.

If the voltage readings are within specifica-

tions, then the windings are good and func-

tioning correctly.

If any one or more of the readings are missing

or not within specifications, then check for

loose or broken wires between the test points

and the stator windings. See the wiring dia-

gram. Make sure that the windings are NOT

grounded internally to the stator iron. If the

leads are intact, then the stator may be faulty.

Replace the stator.

12. Reinstall the right case side using the

5/16” and 3/8” nut drivers and sheet metal

screws.