G-2

ELECTRICAL DIAGRAMS

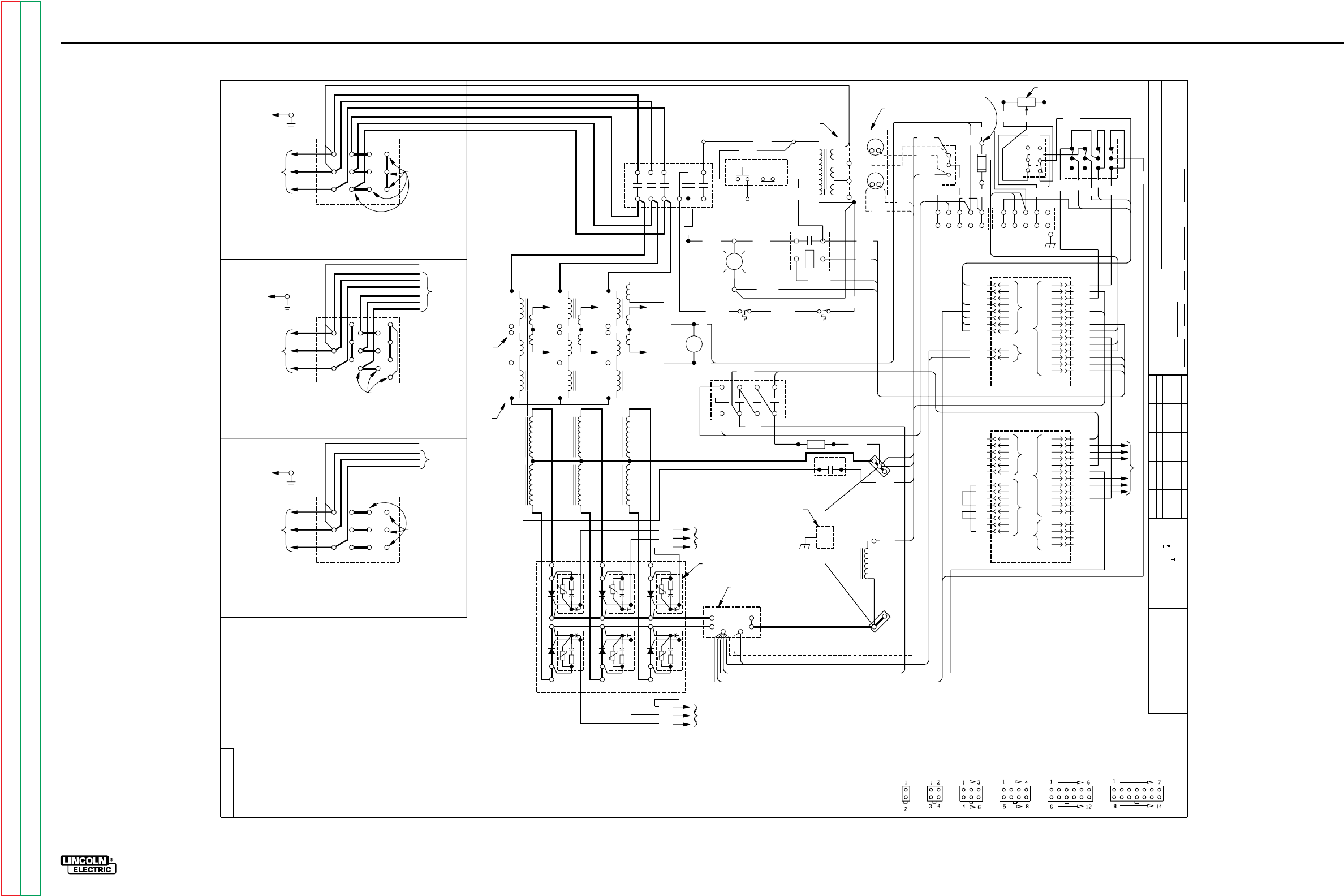

IDEALARC DC1000

Wiring Diagram (Codes 9919, 9920)

9008

Ch'ge. Sht. No.

2-19-93G

3-19-93D

11-19-93C

t

UNLESS OTHERWISE SPECIFIED TOLERANCE

ON HOLE SIZES PER E2056

ON 2 PLACE DECIMALS IS .02

WITH PUBLISHED STANDARDS.

ON 3 PLACE DECIMALS IS .002

ON ALL ANGLES IS .5 OF A DEGREE

MATERIAL TOLERANCE (" ") TO AGREE

THE LINCOLN ELECTRIC CO.

THIS SHEET CONTAINS PROPRIETARY INFORMATION

OWNED BY AND IS

NOT TO BE REPRODUCED, DISCLOSED OR USED

THE LINCOLN ELECTRIC CO.

L

WITHOUT THE EXPRESS PERMISSION OF

4

5

6

9

8

7

1

2

3

L2

L1

H1

H2

TO GROUND PER

NATIONAL ELECTRICAL

CODE

SUPPLY

POWER

TO

3 PHASE

TO

PRIMARY

COILS

SINGLE OR DUAL VOLTAGE INPUT PANEL

SHOWN CONNECTED FOR LOW VOLTAGE

9

8

7

1

2

3

L2

L1

H1

H3

TO GROUND PER

NATIONAL ELECTRICAL

CODE

SUPPLY

POWER

TO

3 PHASE

SHOWN CONNECTED FOR 380 VOLTS

380 VOLTS OR TRIPLE VOLTAGE INPUT PANEL

L3

L3

6

4

5

6

12

10

11

TO PRIMARY COILS

TO T2

TO

1CR

4

5

6

15

14

13

7

8

9

L2

L1

H1

H2

TO GROUND PER

NATIONAL ELECTRICAL

CODE

SUPPLY

POWER

TO

3 PHASE

TO

PRIMARY

COILS

SHOWN CONNECTED FOR LOW VOLTAGE

L3

380/ 500 VOLTS OR 460/ 575 VOLTS

INPUT PANEL

TO T2

TO

1CR

1

S

4

13

7

S

10

T1

S

203

S

204

2

S

S

S

S

S

S

S

S

5

14

8

11

205

206

3

6

15

9

12

207

208

S

32A

31

N.A.

N.B.

1CR

FAN

MOTOR

31

32A

STOP

START

212

211

211

SW1

R3

5

7

A

B

2CR

PILOT

LIGHT

271

R

271

256

257

257A

SECONDARY

THERMOSTAT

CHOKE

THERMOSTAT

X2

255

X1

T2

H4

H3

H2

H1

N.C.

256

255

235

233

+

+

-

-

VM

AM

216

215

210

222

216

222

SW2

21

4

2

31

32

2

32A

F1

32

31

NEG

21

T.S.2

METER KIT

(OPTIONAL)

CENTER TERMINAL

ON FUSE HOLDER

73

74

75

76

77

T.S.3

B

A

31

4

7

8

5

6

9

4CR

215

214

4

215

217

R2

SEC

SEC

SCR

SCR

SCR

SCR SCR

SCR

3

1

5

2

4

6

G1

G3

G5

GATE LEADS

TO FIRING CIRCUIT

P.C. BOARD

SCR SNUBBERS

G6

G4

G2

GATE LEADS

TO FIRING CIRCUIT

P.C. BOARD

OUTPUT SHUNT

50 MV

215

210

+

-

210

3CR

222

222

222

220

OUTPUT

SNUBBER

+

-

1000 AMP

OUTPUT

L1

500 AMP

OUTPUT

216

226

SW3

76

77

OUTPUT CONTROL

R1

75

236

237

229

224

266

221

215

CC

CVI

CVS

SW4

238

230

226

1

2

3

4

5

6

7

8

9

10

11

12

13

14

221

222

230

220

233

74

231

75

226

235

255

256

1

2

3

4

5

6

7

8

1

2

J1

J2

J3

CONTROL

P.C. BOARD

266

229

215

224

73

238

210

215

1

2

3

4

5

6

7

8

9

10

11

12

214

203

206

215

205

207

1

2

3

4

5

6

1

J5

J4

J7

P.C. BOARD

1

2

3

4

204

215

208

231

Y

X

Z

G1

G2

G3

G4

G5

G6

FIRING

CIRCUIT

2

3

4

5

6

7

8

J6

A

A'

B

B'

C

C'

LEGEND

SW1 INPUT POWER

SW4 WELDING MODE

SW2 ELECTRODE POLARITY

SW3 OUTPUT CONTROL

F1 8 AMP SLOW BLOW FUSE

R1 10K OHM POTENTIOMETER

R2 30 OHM, 300 W

R3 10 OHM, 50 W (20W ON EARLIER MODELS)

2CR FAULT PROTECTION RELAY

3CR CURRENT ACTIVATED REED SWITCH

4CR OUTPUT PILOT RELAY

T1 MAIN POWER TRANSFORMER

L1 LOW CURRENT WELDING CHOKE

T2 CONTROL TRANSFORMER

1CR INPUT CONTACTOR

ELECTRICAL SYMBOLS PER E1537

NOTES:

N.A. 13, 14, AND 15 CONNECTIONS PRESENT

ONLY.

ON 380/500 AND 460/575 MACHINES

N.B. 10,11, AND 12 CONNECTIONS NOT

VOLTAGE MACHINES.

PRESENT ON 380V. OR TRIPLE

N.C. CONNECTIONS TO H2, H3, OR H4

DEPENDS ON INPUT VOLTAGE. SEE

INPUT SUPPLY CONNECTION

APPEARS ON 380V AND TRIPLE

INSTRUCTIONS. H4 CONNECTION

VOLTAGE MACHINES ONLY.

J3

J1

CONNECTOR CAVITY NUMBERING SEQUENCE

(VIEWED FROM COMPONENT SIDE OF BOARD)

J6

J4

J2, J7

J5

IDEALARC DC-1000

WIRING DIAGRAM

DAD

NONE

9008

L8234

J.J. 7-30-92

THE LINCOLN ELECTRIC CO.

CLEVELAND, OHIO U.S.A.

EQUIP.

TYPE

SCALE

SUBJECT

DR

DATE

CHK

REF.

SUP'S'D'G

SHT.

NO.

L

POS

TO T1 AUXILIARY WINDING

P.C. BOARD

G-2

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The wiring diagram specific to your code is pasted inside one of the enclosure panels of your machine.