Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

E-2

THEORY OF OPERATION

E-2

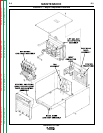

INPUT LINE VOLTAGE, CONTAC-

TOR, AND MAIN TRANSFORMER

The desired three phase power is connected to the

DC-1000 through an Input Contactor located in the

input box at the rear of the machine. Two phases of the

input lines are also connected to the Control

Transformer which supplies power to the Contactor

Hold-In Circuit. The Contactor Hold-In Circuit will dis-

able the Input Contactor if the DC-1000 is overloaded

or overheated.

A Reconnect Panel allows the user to configure the

machine for the desired input voltage. This AC input

voltage is applied to the primary of the Main

Transformer. The transformer changes the high volt-

age, low current input power to a low voltage, high

current output. The finishes or “neutrals” of the

main secondary coils are connected together and

the six starts of the secondary windings are con-

nected to the rectifier assembly. In addition, the

main transformer also has an isolated 115 VAC

auxiliary winding that supplies 115 VAC to operate

the cooling fan and offers 8 amps of auxiliary power

to operate wire feeding equipment. The three 75

VAC phase angle windings are also housed in the

Main Transformer assembly. These windings pro-

vide power and “timing” to the Firing Board.

FIGURE E.2 - Input Line Voltage, Contactor and Main Transformer

IDEALARC DC-1000

NOTE: Unshaded areas of block logic diagrams are the subject of discussion.

GENERAL DESCRIPTION

The DC 1000 is an SCR - controlled DC power

source. It is designed to be controlled with a single

range potentiometer ouptut control. It can be used

for submerged arc or open arc automatic and semi-

automatic welding.