C-2

ACCESSORIES

C-2

OPTIONS/ACCESSORIES

• Remote Control Box Assembly (K775)

• LN-7

• LN-8

}

Semi-Automatic Wire Feeders

• LN-9

• NA-3

• NA-5

}

Automatic Wire Feeders

• LT-7 and LT-56 Tractors

METERS

Optional factory-installed voltmeter and ammeter are

available.

REMOTE OUTPUT CONTROL -

(OPTIONAL)

The K775 Remote Output Control consists of a control

box with 28 ft. (8.4 m) four conductor cable. This con-

nects to terminals #75, #76, #77 on the terminal strip,

and the case grounding screw marked with the sym-

bol on the machine. These terminals are made

available by opening the terminal access cover on the

case front. This control will give the same control as

the output control on the machine.

CONNECTIONS FOR SEMI-AUTO-

MATIC OR AUTOMATIC WIRE

FEEDER CONTROL

1. Set the ON/OFF PUSH BUTTON to OFF.

2. Locate and open the hinged access door on the

Front Case Assembly.

3. Insert control cable through the strain relief box

connector and pull enough cable through to reach

the terminal strip.

4. Connect the automatic wire feeder control cable to

the terminal strip. See corresponding connection

diagram in this section of the manual, or the

instructions included with the wire feeder.

5. Connect the wire feeder grounding wire to the

chassis ground screw marked with the symbol .

NOTE: The IDEALARC DC-1000 Auxiliary Power

Circuit (at #31 and #32 on the terminal strip) supplies

115-volt AC power to the wire feeding equipment. The

circuit has a 1000 volt ampere rating. An 8-amp slow

blow fuse on the machine’s control panel protects the

auxiliary power supply from excessive overloads or

short circuits.

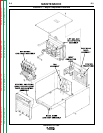

CONNECTING THE NA-3 OR LT-7 TO

IDEALARC DC-1000

1. Disconnect main AC input power to the IDE-

ALARC DC-1000.

2. Set IDEALARC DC-1000 ON/OFF PUSH BUT-

TON to OFF.

3. Connect the wire feeder control cable leads to the

IDEALARC DC-1000 terminal strip as shown in

Figure C.1.

4. Connect the wire feeder control cable ground lead

to the frame terminal marked .

5. Extend wire feeder control cable lead #21 so it

can be connected directly to the work piece.

a. Make a bolted connection using AWG #14

or larger insulated wire.

b. Tape the bolted connection with insulating

tape.

NOTE: An S-16586-X remote voltage sensing work

lead is available for this purpose.

c. Keep the #21 lead electrically separate

from the work cable circuit and connection.

IDEALARC DC-1000

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

FIGURE C.1 - NA-3 or LT-7 Wire Feeder

Connection to the IDEALARC DC-1000

CAUTION

The IDEALARC DC-1000 must be properly grounded.

____________________________________________________