E-4

THEORY OF OPERATION

E-4

PROTECTION DEVICES AND

CIRCUITS (CONTACTOR HOLD-IN)

Two thermostats protect the DC-1000 from exces-

sive operating temperatures. Excessive operating

temperatures may be caused by a lack of cooling air

or operating the machine beyond the duty cycle and

output rating. If excessive operating temperature

should occur, the thermostat(s) will deactivate the

input contactor, turning the machine off. The input

contactor will remain open until the machine cools.

The machine can then be restarted by operating the

start push button.

Upon restart, if the fan does not turn or the air intake

louvers are obstructed, then the input power must

be removed and the fan problem or air obstruction

be corrected.

The DC-1000 is also protected against high current

overloads. This electronic protection circuit senses

an overload on the power source and opens the

input contactor should the overload remain for a

predetermined time. If the overload is great the

machine will shut down immediately. The input con-

tactor will remain open until the start push button is

operated.

The Remote Control circuit is also protected from

“grounds” or voltage intrusions. If the #73, #74, #75,

#76 or #77 leads come in contact with either of the

machine’s output cables, the DC-1000 will only

operate at a minimum output or the input contactor

will open.

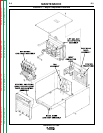

FIGURE E.4 - Protection Devices and Circuits (Contactor Hold-In)

IDEALARC DC-1000

NOTE: Unshaded areas of block logic diagrams are the subject of discussion.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC