F-37

TROUBLESHOOTING & REPAIR

F-37

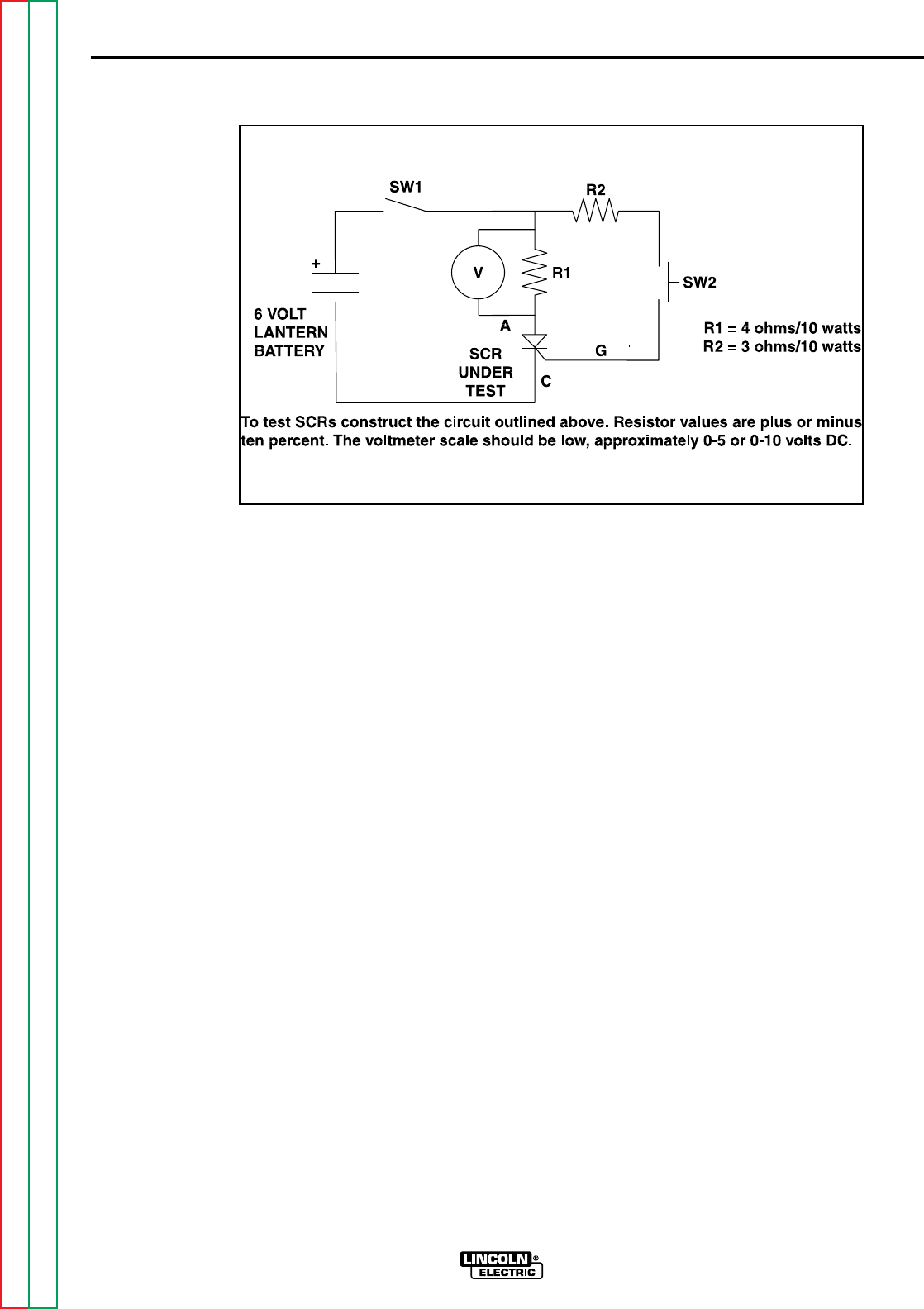

5. To test SCRs, construct the circuit

outlined in Figure F.17. Use one 6V

lantern battery. Resistor values are

in ohms ±10%. The voltmeter scale

should be low, approximately 0-5 or

0-10 volts.

BATTERY TEST

Check the battery by shorting leads (A)

and (C) and then close switch SW1.

Replace battery if voltage is less than

4.5 volts.

A. Connect SCR into the test circuit as

shown (A) lead to anode (C) lead to

cathode and (G) lead to the gate.

B. Close switch SW1 (switch SW2

should open), voltmeter should read

zero. If the voltmeter reads higher

than zero the SCR is shorted.

NOTE: Do not disassemble the heat

sinks.

6. With switch SW1 closed, close

switch SW2 for two seconds and

release. The voltmeter should read

3 to 6 volts before and after switch

SW2 is released. If the voltmeter

does not read, or reads only while

SW2 is depressed, the SCR or bat-

tery is defective (repeat Battery

Test Procedure).

7. Open switch SW1, disconnect the

gate lead (G) and reverse the (A)

and (C) leads on the SCR. Close

switch SW2. The voltmeter should

read zero. If the voltage is higher

than zero, the SCR is shorted.

8. Replace any SCR assembly that

does not pass test in Step 4.

ACTIVE SCR TEST

IDEALARC DC-1000

FIGURE F.17- Silicon Controlled Rectifier (SCR) Test Setup

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC