Workman 200 Spray System

Page 3 – 9

Spray System

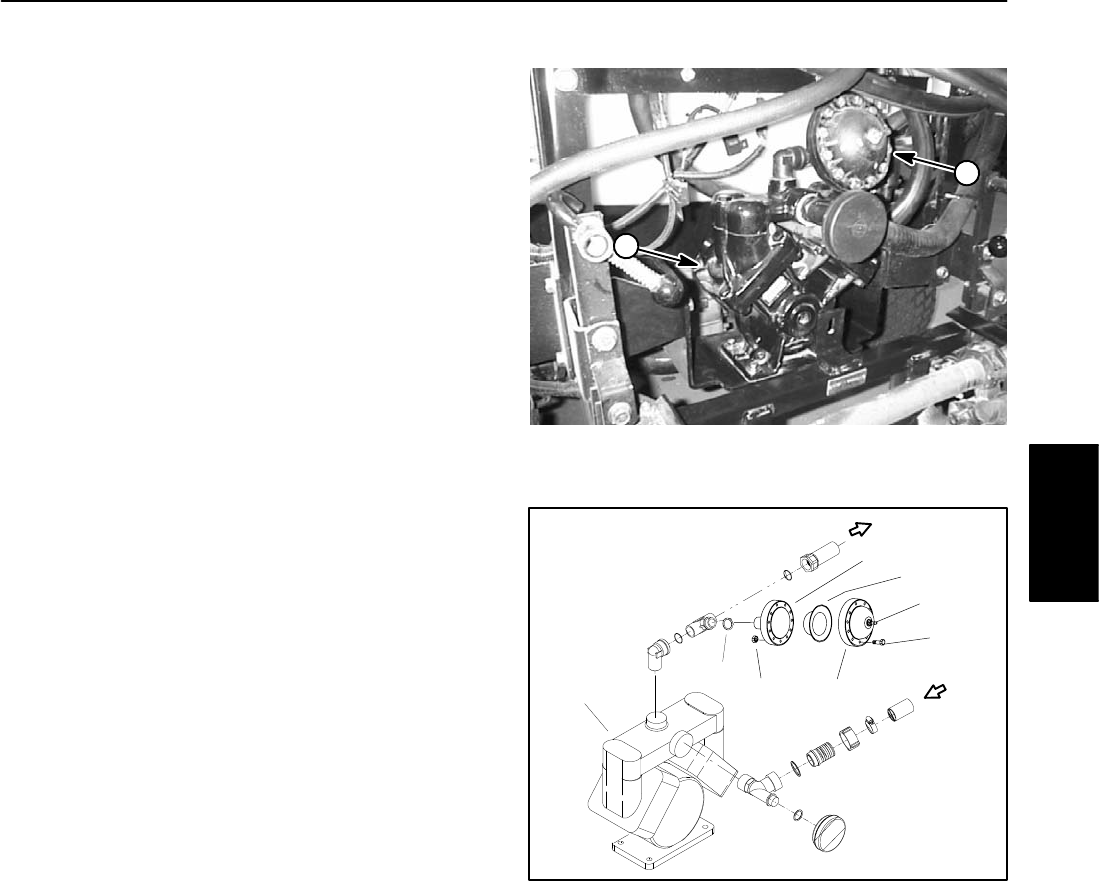

Pressure Dampener

The pressure dampener is mounted to the pressure line

at the spray pump (Fig. 4) and is used to smooth system

pressure pulsation. Adjust air pressure on the pressure

dampener from 12 to 15 PSI (.82 to 1.03 bar).

IMPORTANT: Any fluid in the pressure dampener

will include spray system chemicals so take neces-

sary precautions when working with the dampener.

Use appropriate protective equipment: protective

clothing, chemical resistant gloves, and eye protec-

tion.

If fluid is present when pressure in the dampener is

checked, the diaphragm in the pressure dampener is

damaged and should be replaced.

Dampener Service (Fig. 5)

IMPORTANT: Make sure to neutralize and remove

chemicals from pump and hoses before loosening

and removing spray system components.

1. Loosen and remove cap screws and nuts that secure

diaphragm between housings.

2. Remove diaphragm from dampener.

3. Replace diaphragm and reassemble dampener.

1. Spray pump 2. Pressure dampener

Figure 4

2

1

1. Spray pump

2. O–ring

3. Hex nut (12 used)

4. Rear housing

5. Diaphragm

6. Front housing

7. Cap screw (12 used)

8. Air valve

Figure 5

1

2

3

4

5

6

7

8

Spray

System