Actuator Oil Level

Under normal conditions, actuator oil level should re-

main constant. If any oil is spilled from the reservoir dur-

ing air bleeding, the oil level in the actuator should be

checked and adjusted.

1. Thoroughly clean the exterior of the actuator to pre-

vent contaminates from entering the actuator.

2. Make sure that the actuator cylinder is fully retracted.

IMPORTANT: To prevent actuator damage, use vise

with protective jaws when clamping actuator.

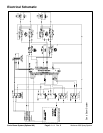

3. Place the actuator in a vise making sure that actuator

is clamped in the area identified in Figure 55. Use just

enough clamping force to hold the housing securely.

Make sure that the reservoir plug is orientated up.

Figure 55

CYLINDER

VISE

CLAMPING

ELECTRIC

PLUG

UP

DOWN

AREA

MOTOR

RESERVOIR

RESERVOIR

CAUTION

The actuator reservoir is pressurized. If the res-

ervoir plug is removed too quickly, oil under

pressure can be ejected from the actuator.

4. Slowly loosen and remove the reservoir plug at the

top of the reservoir.

5. Using a light through the plug hole, confirm that the

reservoir oil is clear. If the oil appears milky, perform ac

-

tuator air bleeding procedure.

6. Use a clean rod to identify the level of oil in reservoir.

Distance from plug fitting to oil level should be .984” (25

mm). If necessary, add ISO VG 32 mineral oil to actuator

reservoir to adjust oil level.

Spray

System

0.984”

(25 mm)

7. When oil level is correct, use a 12 volt DC power sup-

ply to power the actuator and extend the cylinder com-

pletely.

IMPORTANT: To ensure proper reservoir pressure,

make sure that cylinder is extended before instal

-

ling reservoir plug.

8. Install the reservoir plug and torque from 45 to 60 in–

lb (5.1 to 6.8 N–m).

Actuator Disposal

If actuator disposal is necessary, remove hydraulic oil

from actuator before disposal.

1. Open actuator reservoir (see Steps 1 through 4 in

Actuator Air Bleeding).

2. Drain oil from actuator.

Figure 56

Workman 200 Spray System

Page 3 – 51

Rev. A

Spray System