IMPORTANT: Make sure to remove and neutralize

chemicals from spray components before disas

-

sembly. Wear protective clothing, chemical resist-

ant gloves, and eye protection during repair.

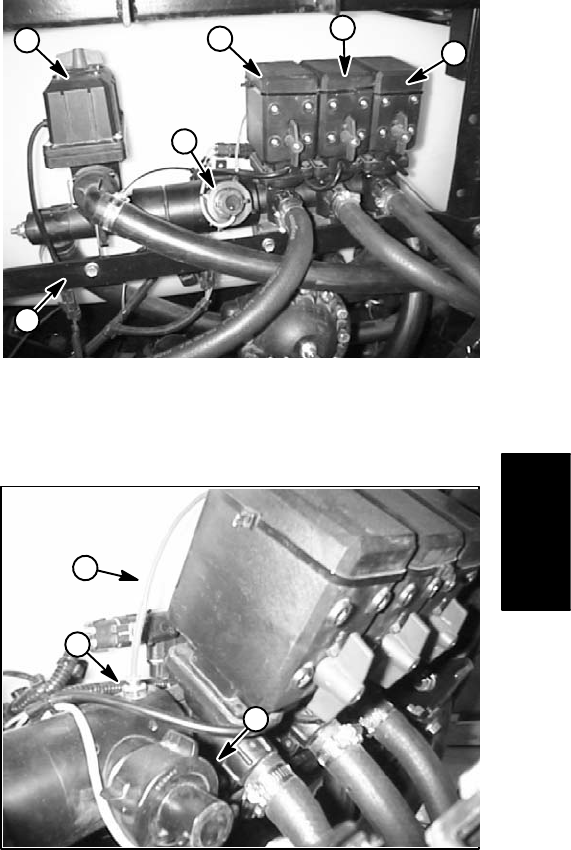

Removal (Fig. 21)

1. Park machine on a level surface, stop engine, en-

gage parking brake, and remove key from the ignition

switch.

2. Label hoses for proper installation after repairs are

completed. Loosen hose clamps and disconnect hoses

from spray control.

3. Unplug electrical connectors from rate control motor,

flowmeter, and three (3) boom valve motors from ma

-

chine electrical harness.

4. Remove pressure gauge tube from coupler on back

of flowmeter housing (Fig. 23).

5. Remove three (3) flange head screws that secure

spray control assembly to valve mounting bar. Remove

spray control assembly from machine.

6. Remove spray control components as required us-

ing Figure 21 as a guide. Discard all removed o–rings

and gaskets.

Assembly (Fig. 21)

NOTE: Coat all o–rings with vegetable oil before instal-

lation to reduce the chance of damage during assembly.

1. Install spray control components using Figure 21 as

a guide. Replace all removed o–rings and gaskets.

2. Before installing rod (Item 2) into assembly, thread

nut (item 1) fully onto rod end that has fewer threads.

Make sure that o–ring (Item 3) is not damaged during

installation over rod. To secure assembly, torque nut 71

in–lb (8 N–m).

3. Position spray control assembly to valve mounting

bar and secure with three (3) flange head screws.

4. Install hoses to correct locations on spray control as-

sembly. Secure hoses with hose clamps.

5. Install pressure gauge tube to coupler on back of

flowmeter housing (Fig. 23).

6. Plug electrical connectors from rate control motor,

flowmeter, and three (3) boom valve motors to machine

electrical harness.

7. Operate spray system and check for leaks.

1

2

5

3

6

4

Figure 22

1. Rate control motor 4. Center boom valve motor

2. Flowmeter 5. RH boom valve motor

3. LH boom valve motor 6. Valve mounting bar

1

2

3

Figure 23

1. Flowmeter 3. Coupler

2. Pressure gauge tube

Spray

System

Workman 200 Spray System

Page 3 – 23

Spray System