Rev. B

Page 3 -- 27.2Workman 200 Spray System Spray System

Assembly (Fig. 28.1)

1. To installvalve motorcover toregulating valve motor

(Fig. 28.3):

A. Connect cover wires to motor wires. Make sure

that cover wire color is the same as the motor wire

color when connecting wires.

B. Carefully rotate cover onto valve motor taking

care to not damage wires.

C. Tighten screws to secure cover to valve motor.

NOTE: CoatallO--ringswith vegetableoilbeforeinstal-

lation toreducethe chanceof damageduringassembly.

2. Assemble regulating valve assembly using Figure

28.1 as a guide.

3. Attach regulating valve assembly to spray control

and then installspray control assembly tomachine (see

Spray Control Assembly (Serial Numbers Above

310000000) Installation in this section).

Piston Valve Service (Fig. 28.4)

1. Remove hosebarb from bottom of valve motor to al-

low access to piston valve.

2. Make sure that valve is closed. If valve is not closed,

spring above piston valve will be under compression

and maydamagevalve motoror pistonvalve duringdis-

assembly. End of piston valve will extend into bottom of

valve motor housing when valve is closed. Ifnecessary,

reconnect motor to machine wire harness and close

valve before removing piston valve.

3. Use 3mm allen wrench to loosen and remove piston

valve assembly from valve motor. Locate and retrieve

spring from above piston valve.

4. Inspectsealsonpistonvalveassembly.O--ringintop

groove ofpiston valve assemblyis available separately.

If lower two (2) seals in piston valve are worn or dam-

aged, replace piston valve assembly. The piston valve

is not designed to be disassembled.

5. Apply silicone grease to seals on piston valve as-

sembly.

6. Position spring into valve motor housing. Use 3mm

allen wrench to secure piston valve assembly to valve

motor.

7. Secure hosebarb to bottom of valve motor.

1. Boom valve manifold

2. Flowmeter

3. Regulating valve

Figure 28.2

2

1

3

1. Valve motor assembly

2. Valve motor cover

3. Wire connector

4. Socket screw (4 used)

5. Phillips screw (2 used)

Figure 28.3

1

2

5

4

3

3

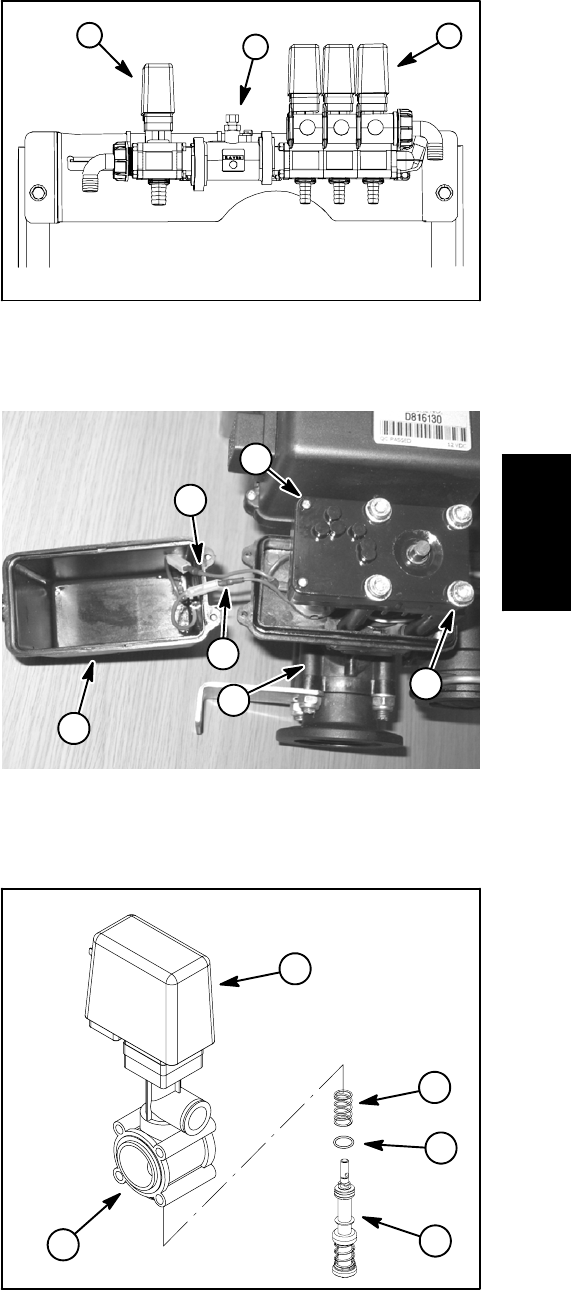

1. Valve motor assembly

2. Piston valve assembly

3. Valve seal

4. Spring

5. Valve motor cover

Figure 28.4

2

1

3

4

5

Spray

System