6 – 3

Vission 20/20 • Operation and Service Manual •Vilter/Emerson • 35391SC 1.8.5153

The auto-cycle function will operate only in local “Auto”

mode and Direct I/O “Remote Auto” mode. If the au-

to-cycle feature is enabled while running in any other

remote mode, the function will simply be ignored.

However, the Minimum slide position will continue to

be respected in Remote “Auto” mode. If the compres-

sor changes from a remote mode back to Local “Auto”

mode, the auto-cycle feature will operate normally.

NOTE

When the Pump-down Feature is enabled, the Auto-

cycle setpoints are automatically disabled. Pump-

down mode will cause the compressor to cycle off

via the Pump-down Stop Pressure setpoint, and will

not allow the compressor to start again.

Enable:

• Enables the Auto-cycle control. Uncheck the box to

disable the Auto-cycle set-points.

Start Pressure:

• When the suction pressure meets or exceeds this set-

point, the compressor will start.

Start Delay:

• Delays the compressor from starting when the suc-

tion pressure meets or exceeds this setpoint.

Stop Pressure:

• When the suction pressure meets or falls below this

setpoint, the compressor will stop.

Stop Delay:

• Delays the compressor from stopping when the suc-

tion pressure meets or exceeds this setpoint.

Minimum Slide Position:

• The minimum capacity slide position that the com-

pressor is allowed to run at.

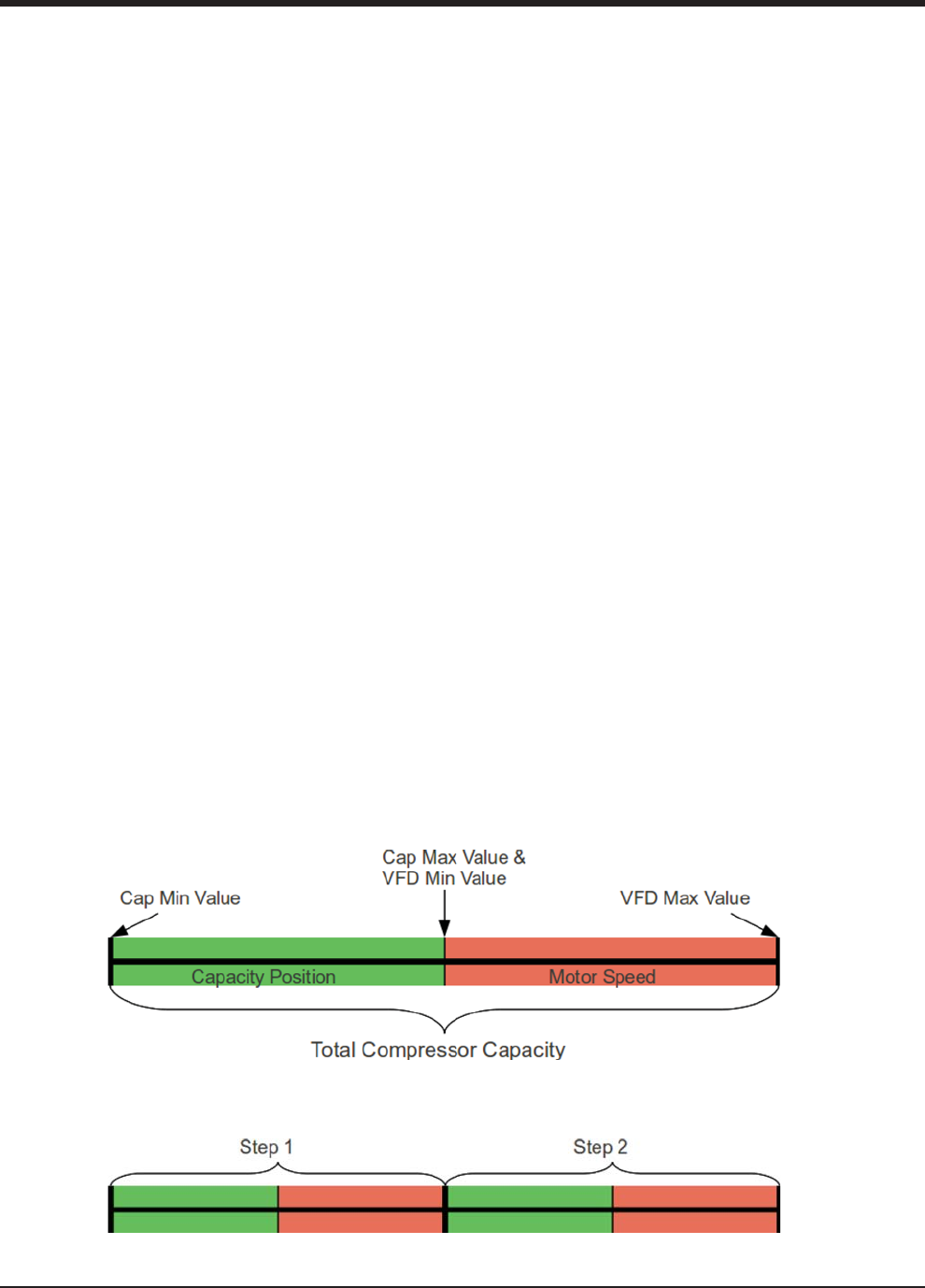

Variable Frequency Drive (VFD)

The VFD page is where the operator can tune the mo-

tor VFD for desired operation. A Vilter compressor uses

the variable speed of a VFD controlled motor to vary

the amount of work or capacity of the compressor. The

basic one step VFD control will use the capacity slide to

control the fi rst half of the total available capacity and

the motor speed to control the second half of the total

available capacity, see Figure 6-3. VFD One-Step Control

Method. For example, if the compressor needs to load

to 100% of its capacity. The control algorithm will fi rst

move the capacity slide to its maximum position, then

the motor speed will ramp up to its maximum speed.

In the unloading direction, the motor speed will ramp

down to its minimum speed, then the capacity slide will

move to its minimum position.

The two-step control method works much like the one-

step method but divides the control into four sections,

see Figure 6-4. VFD Two-Step Control Method. While

loading; the compressor will fi rst move the capacity

slide to the maximum set for step one then speed up the

motor to its maximum speed for the same step. Once

step one has completed, the control algorithm will again

move the capacity slide to the maximum position and

the maximum speed of step two. At this point the com-

pressor would be fully loaded. Unloading occurs in the

reverse direction. The two-step control method is not

typical for most installations and is normally used when

a Vilter engineer recommends it.

Section 6 • Compressor Control

Figure 6-3. VFD One-Step Control Method

Figure 6-4. VFD Two-Step Control Method