14 – 6

Vission 20/20 • Operation and Service Manual •Vilter/Emerson • 35391SC 1.8.5153

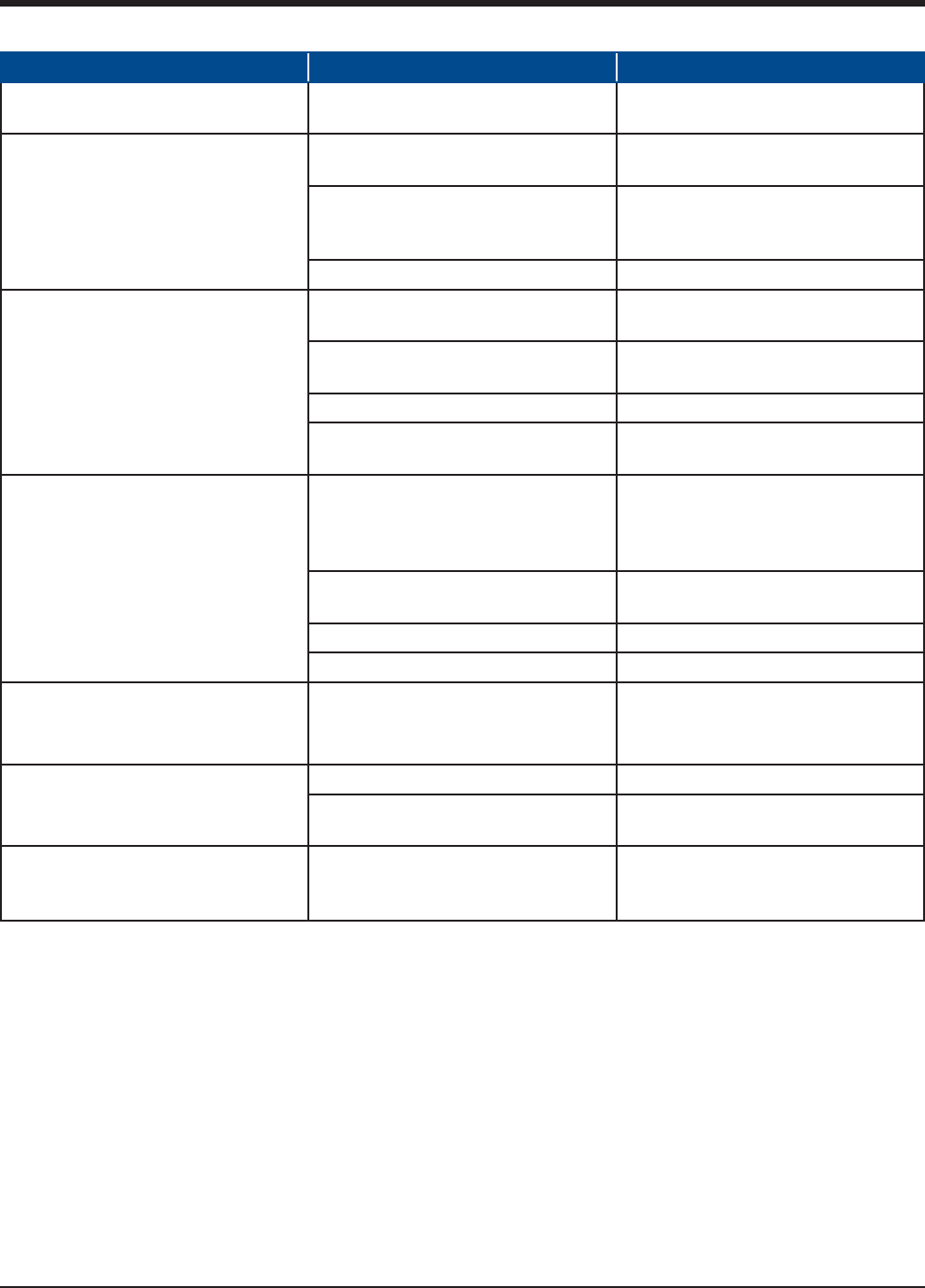

Table 14-2. Slide Valve Troubleshooting Guide (2 of 2)

Problem Reason Solution

There is a rapid clicking noise when

the mot

or is operating. (Continued)

The position sensor’s EEPROM

memory has failed.

Replace the actuator.

There is a rapid clicking noise when

the motor is operating.

The photochopper is misaligned

with the slotted optocouplers.

Try to realign or replace the actuator.

The photochopper is positioned too

low on the motor shaft.

Adjust the photochopper so that

the fence extends further into the

optocoupler slots.

A motor bearing has failed. Replace the actuator.

The motor operates in one direction

only.

There is a loose connection in the

screw terminal blocks.

Tighten.

There is a loose or dirty connection

in the yellow Turck cable.

Clean and tighten.

The position sensor has failed. Replace the actuator.

There is a broken motor lead or

winding.

Replace the actuator.

The motor will not move in either

direction.

The thermal switch has tripped be-

cause the motor is overheated.

The motor will resume operation

when it cools. This could be caused

by a malfunctioning control panel.

Consult the factory.

Any of the reasons listed in “The mo-

tor operates in one direction only”.

See above.

The command shaft is jammed. Free the command shaft.

Broken gears in the gear-motor. Replace the actuator.

The motor runs intermittently,

several minutes on, several minutes

off.

Motor is overheating and the ther-

mal switch is tripping.

This could be caused by a malfunc-

tioning control panel. Consult the

factory.

The motor runs sporadically.

Bad thermal switch. Replace the actuator.

Any of the reasons listed in “The mo-

tor will not move in either direction”.

See above.

The motor runs but output shaft will

not turn.

Stripped gears inside the gear rotor,

or the armature has come unpressed

from the armature shaft.

Replace the actuator.

Section 14 • Slide Calibration