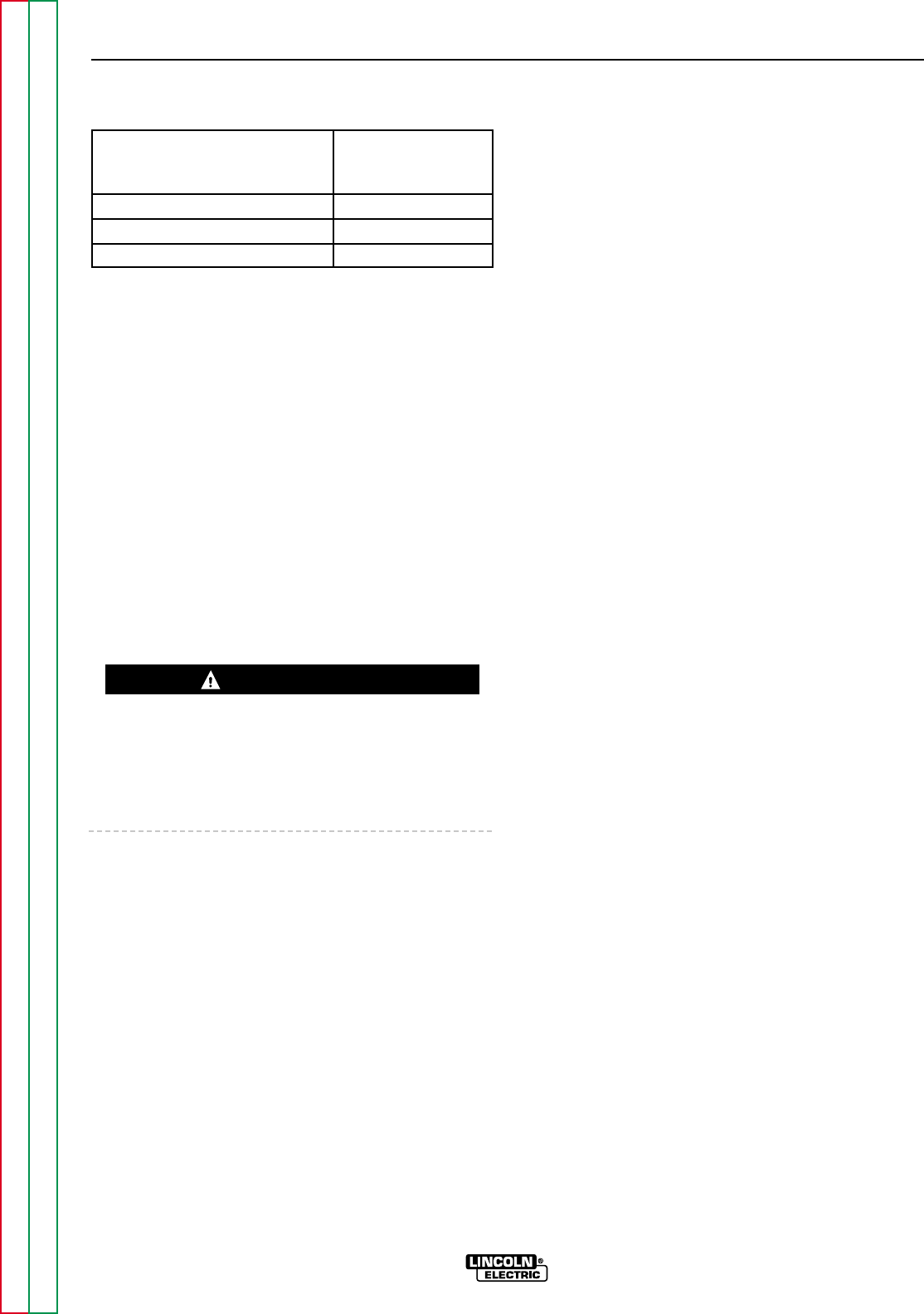

TABLE A.1 – TOTAL COMBINED LENGTH

OF ELECTRODE AND WORK CABLES

Cable

Cable Size for

Length

250 Amps

100% Duty Cycle

0-100 ft. (0-30 meters) 1 AWG

100-200 ft. (30-46 meters) 1 AWG

150-200 ft. (46-61 meters) 1/0 AWG

CABLE INSTALLATION

Install the welding cables to your Ranger 250 as fol-

lows.

1. The engine must be OFF to install welding cables.

2. Remove the flanged nuts from the output terminals.

3. Connect the electrode holder and work cables to

the weld output terminals. The terminals are iden-

tified on the case front.

4. Tighten the flanged nuts securely.

5. Be certain that the metal piece you are welding (the

“work”) is properly connected to the work clamp

and cable.

6. Check and tighten the connections periodically.

• Loose connections will cause the output terminals to

overheat. The terminals may eventually melt.

• Do not cross the welding cables at the output termi-

nal connection. Keep the cables isolated and sepa-

rate from one another.

AUXILIARY POWER RECEPTACLES

The auxiliary power of the Ranger 250 consists of two

20 amp-120 VAC (5-20R) duplex receptacles and one

50 amp 120/240 VAC (14-50R) receptacle. The 240

VAC receptacle can be split for single-phase 120 VAC

operation.

The auxiliary power capacity is 8,000 watts of 60 Hz,

single-phase power. The auxiliary power capacity rat-

ing in watts is equivalent to volt-amperes at unity power

factor. The maximum permissible current of the 240

VAC output is 33 amps. The 240 VAC output can be

split to provide two separate 120 VAC outputs with a

maximum permissible current of 33 amps per output to

two separate 120 VAC branch circuits (these circuits

cannot be paralleled). Output voltage is within ±10% at

all loads up to rated capacity.

The 120 VAC auxiliary power receptacles should only

be used with three-wire grounded type plugs or

approved double insulated tools with two-wire plugs.

The current rating of any plug used with the system

must be at least equal to the current capacity of the

associated receptacle.

NOTE: The 240 VAC receptacle has two 120 VAC cir-

cuits, but they are of opposite polarities and cannot be

paralleled.

STANDBY POWER CONNECTIONS

The Ranger 250 is suitable for temporary, standby or

emergency power using the engine manufacturer’s rec-

ommended maintenance schedule.

The Ranger 250 can be permanently installed as a

standby power unit for 240 VAC, three-wire, single-

phase, 35 amp service. Connections must be made by

a licensed electrician who can determine how the

120/240 VAC power can be adapted to the particular

installation and comply with all applicable electrical

codes. The following information can be used as a

guide by the electrician for most applications. Refer to

the connection diagram in Figure A-2.

1. Install the double-pole, double-throw switch

between the power company meter and the

premises disconnect. Switch rating must be the

same or greater than the customer’s premises dis-

connect and service over current protection.

2. Take necessary steps to assure load is limited to

the capacity of the Ranger 250 by installing a 35

amp, 240 VAC double-pole circuit breaker.

Maximum rated load for each leg of the 240 VAC

auxiliary is 33 amperes. Loading above the rated

output will reduce output voltage below the allow-

able ±10% of rated voltage, which may damage

appliances or other motor-driven equipment and

may result in overheating of the Ranger 250 engine

and/or alternator windings.

3. Install a 50 amp, 120/240 VAC plug (NEMA Type

14-50) to the double-pole circuit breaker using No.

6, 4-conductor cable of the desired length. (The 50

amp, 120/240 VAC plug is available in the optional

K802R plug kit or as part number T12153-9.)

4. Plug this cable into the 50 amp, 120/240 VAC

receptacle on the Ranger 250 case front.

INSTALLATION

A-7 A-7

RANGER 250

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

CAUTION