STICK WELDING

The Ranger 250 can be used with a broad range of DC

stick electrodes.

The MODE switch provides two stick welding settings

as follows:

CONSTANT CURRENT (CC-STICK) WELDING

The CC-STICK position of the MODE switch is

designed for horizontal and vertical-up welding with all

types of electrodes, especially low hydrogen. The

OUTPUT control adjusts the full output range for stick

welding.

The ARC control sets the short circuit current during

stick welding (arc-force). Increasing the number from

-10 to +10 increases the short circuit current and pre-

vents sticking of the electrode to the plate while weld-

ing. This can also increase spatter. It is recommended

that the ARC control be set to the minimum number

without electrode sticking. Start with the dial set at 0.

PIPE WELDING

This slope-controlled setting is intended for “out-of-

position” and “downhill” pipe welding where the opera-

tor would like to control the current level by changing

the arc length. The OUTPUT control dial adjusts the full

output range for pipe welding. The ARC control is not

active in the PIPE mode.

OPERATION

B-8 B-8

RANGER 250

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

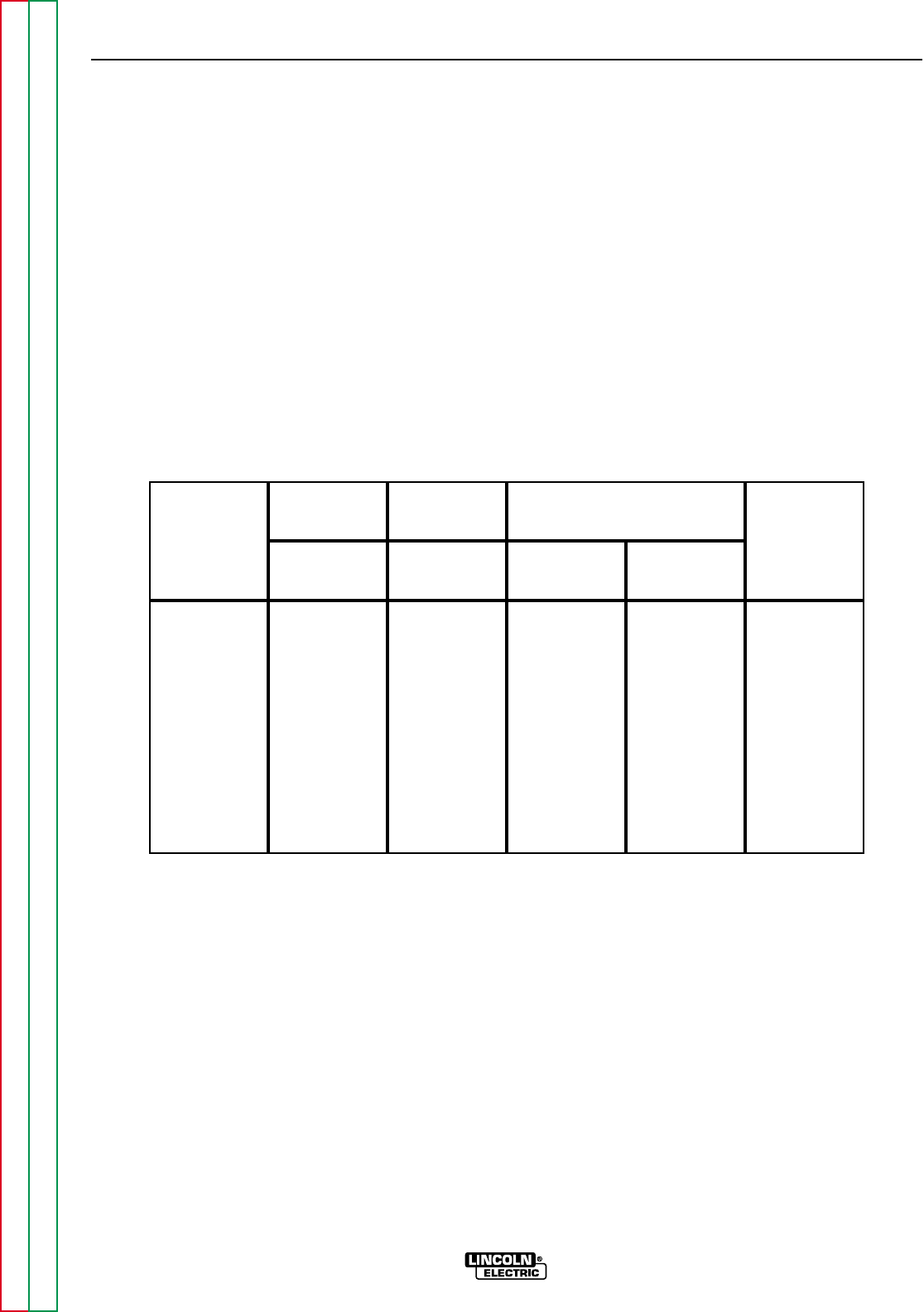

Tungsten

Electrode

Diameter

in. (mm)

2-15

5-20

15-80

70-150

150-250

250-400

400-500

500-750

750-1000

3

3

3

10-20

15-30

25-40

40-55

55-80

180-125

3-8 (2-4)

5-10 (3-5)

5-10 (3-5)

5-10 (3-5)

13-17 (6-8)

15-23 (7-11)

21-25 (10-12)

23-27 (11-13)

28-32 (13-15)

3-8 (2-4)

5-10 (3-5)

5-10 (3-5)

9-13 (4-6)

11-15 (5-7)

11-15 (5-7)

13-17 (6-8)

18-22 (8-10)

23-27 (11-13)

TIG TORCH

Nozzle

Size

4, 5

Approximate Argon Gas Flow Rate

C.F.H. (l/min.)

DCEN (-) DCEP (+)

#4, #5, #6

#5, #6

#6, #7, #8

#8, #10

0 .010 (.25)

0.020 (.50)

0.040 (1.0)

1/16 (1.6)

3/32 (2.4)

1/8 (3.2)

5/32 (4.0)

3/16 (4.8)

1/4 (6.4)

1%, 2%

Thoriated

Tungsten

1%, 2%

Thoriated

Tungsten

Aluminum Stainless Steel

TABLE B.2 – TYPICAL CURRENT RANGES

1

FOR TUNGSTEN ELECTRODES

2

1

When used with argon gas. The current ranges shown must be reduced when using argon/helium or pure helium shield-

ing gases.

2

Tungsten electrodes are classified as follows by the American Welding Society (AWS):

Pure EWP

1% Thoriated EWTh-1

2% Thoriated EWTh-2

Though not yet recognized by the AWS, Ceriated Tungsten is now widely accepted as a substitute for 2% Thoriated

Tungsten in AC and DC applications.

3

DCEP is not commonly used in these sizes.

4

TIG torch nozzle “sizes” are in multiples of 1/16ths of an inch:

# 4 = 1/4 in. (6 mm)

# 5 = 5/16 in. (8 mm)

# 6 = 3/8 in. (10 mm)

# 7 = 7/16 in. (11 mm)

# 8 = 1/2 in. (12.5 mm)

#10 = 5/8 in. (16 mm)

5

TIG torch nozzles are typically made from alumina ceramic. Special applications may require lava nozzles, which are

less prone to breakage, but cannot withstand high temperatures and high duty cycles.