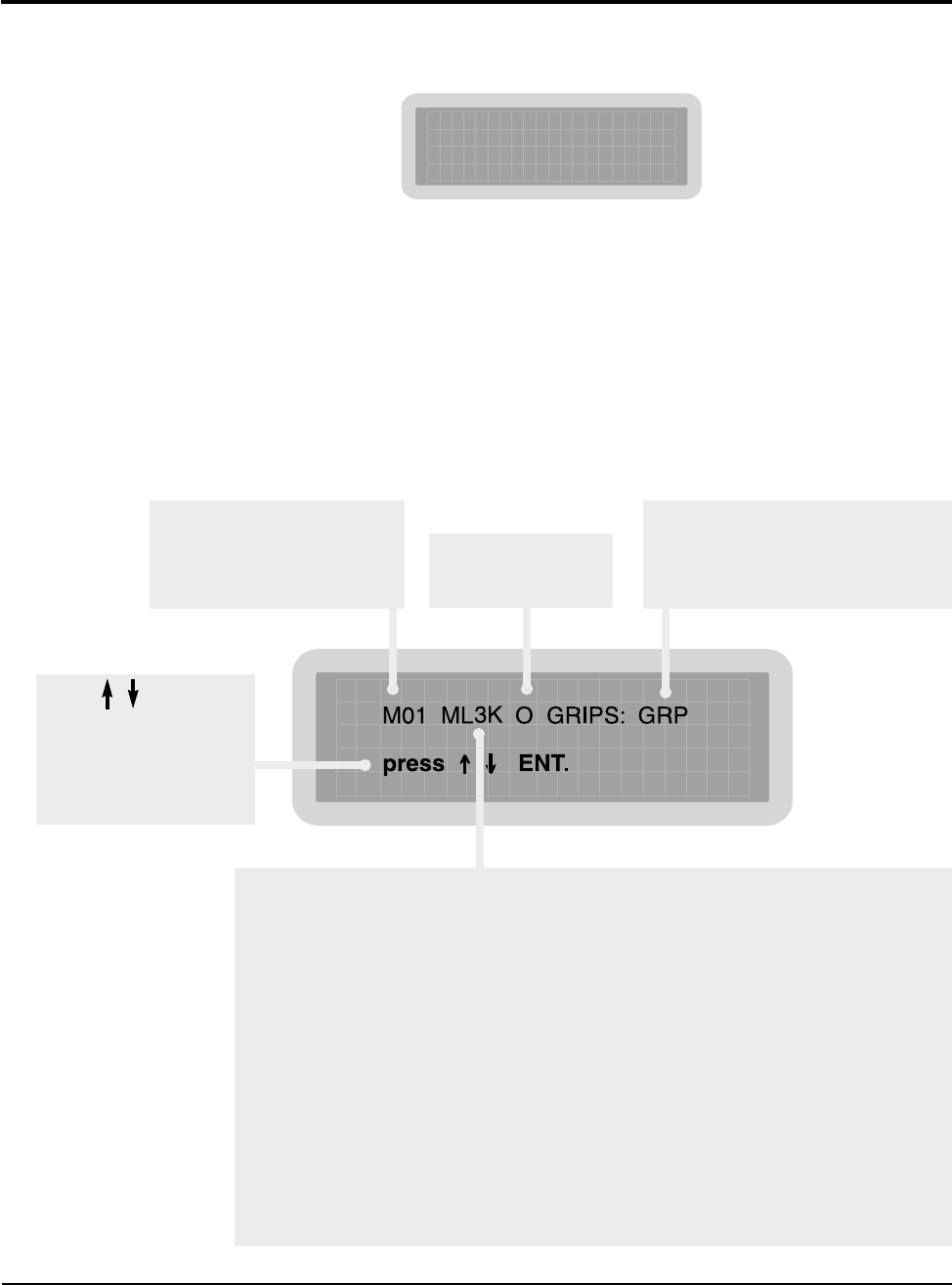

The LED displays the data you input, the status of the robot,

and any error messages.

UCR-150L Robot UGR003/0900

4-4

OPERATION

V

IEWING

INFORMATION

During normal operation the display provides:

● the current mold number

● the motion sequence

● current home position

● the current valve selection

● programming directions

Error codes display during an alarm or error. A typical display

during normal operation is:

press ENT.

Programming directions

to use the Up/Down

arrows to scroll, and

press the Enter button

to save the choice.

Home position

I - above the mold

O - outside the mold

Pick up position

Vertical motion

Main grip release

Vacuum release

GRIPS

GRIP Use grip solenoid valve

VAC Use vacuum solenoid valve

G+V Use grip and vacuum

solenoid valve

Mold Number

The current mold number;

control can be programmed

for up to seven different

molds, M01 to M07.

M Pick up from moveable mold

F Pick up from fixed mold

L L-shaped vertical motion

U U-shaped vertical motion

2 Grip release at arm second descend.

K Grip release at arm second descend and strip motion.

3 Grip release on the way, arm third extended.

M Grip release in the mold area.

2 Vacuum release at arm second descend.

K Vacuum release at arm second extend and strip motion.

3 Vacuum release on the way, arm third extended.

M Vacuum release in mold area.

Motion Sequence