DC Braking (DB) Settings

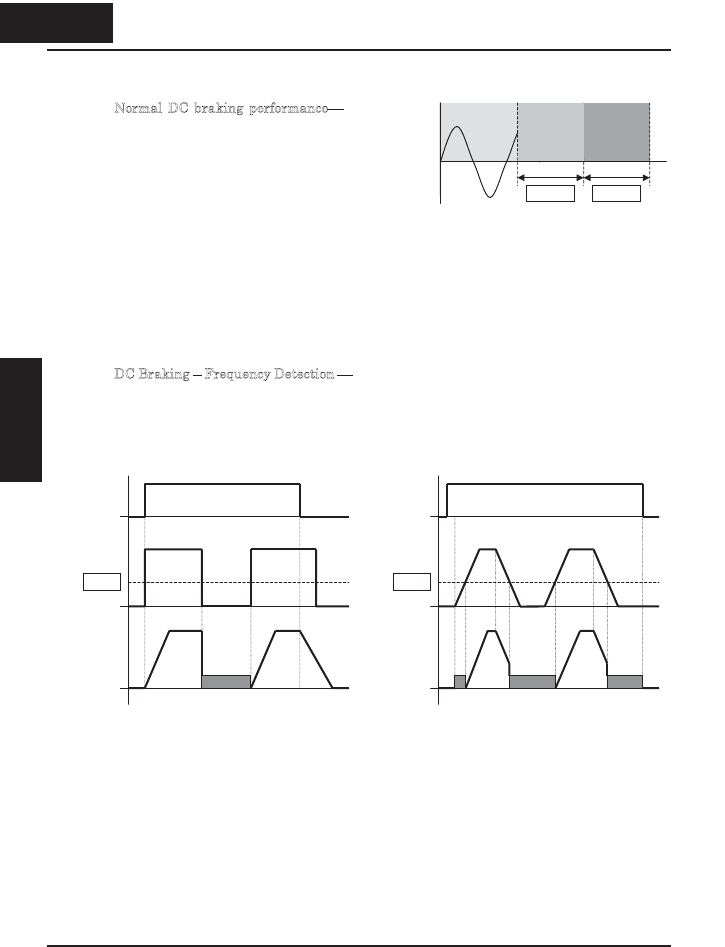

Normal DC braking performance The DC

braking feature can provide additional

stopping torque when compared to a normal

deceleration to a stop. DC braking is

particularly useful at low speeds when

normal deceleration torque is minimal.

When you set A051 to 01 (Enable during

stop), and the RUN command (FW/RV

signal) turns OFF, the inverter injects a DC

voltage into the motor windings during

deceleration below a frequency you can

specify (A052).

The braking power (A054) and duration (A055) can both be set. You can optionally

specify a wait time before DC braking (A053), during which the motor will free run.

D

C Braking – Frequency Detection You can instead set DC braking to operate during

RUN mode only, by setting A051 to 02 (Frequency detection). In this case DC braking

operates when the output frequency comes down to the one you specified in A052 while

the RUN command is still active. Refer to the graphs figures below.

External DB and Internal DC braking are invalid during the frequency detection mode.

Example 1, (above left) shows the performance with A051=02 with a step-changing

frequency reference. In this case, when the reference goes to 0, the inverter immediately

starts DC braking because the set point drops below the value specified in A052. DC

braking continues until the set point exceeds A052. There will be no DC braking at next

downward transition because the FW input is OFF.

Example 2, (above right) shows a gradually changing frequency reference, for example

by analog input. In this case, there will be a DC braking period at starting because the

frequency set point is lower than the value specified in A052.

Running DC brakeFree run

+

0

-

t

A053 A055

FW

ON

F-SET

A052

DB

Ex.1) Step change in F-SET.

F-OUT

FW

ON

F-SET

A052

Ex.2) Analog change in F-SET.

F-OUT

DB DB DB

318

Configuring Drive

Parameters

3 18

&RQ¿JXULQJ'ULYH

Parameters