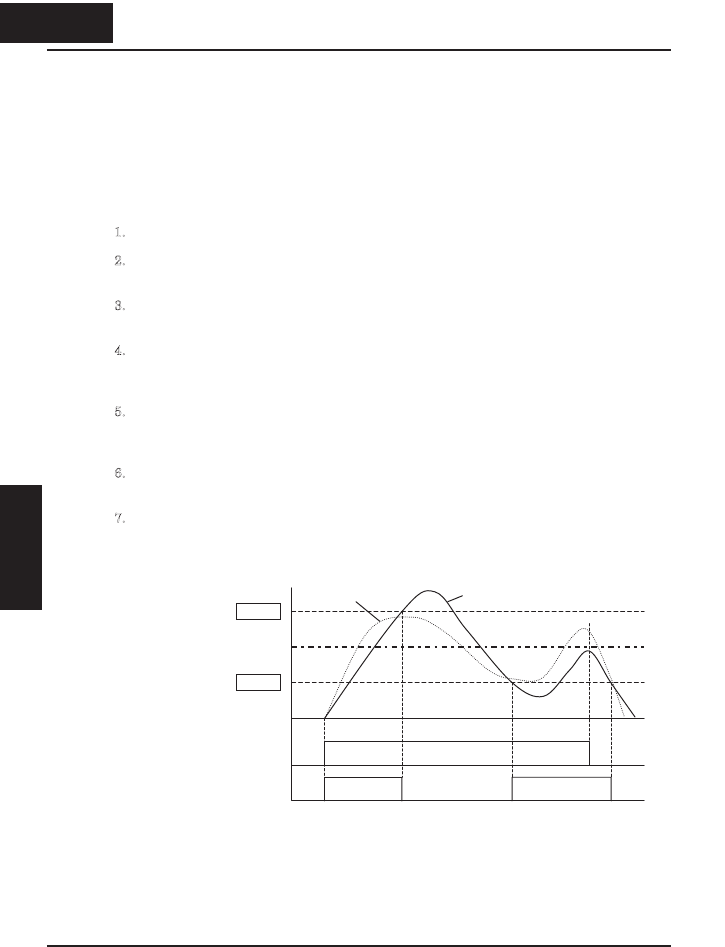

To use the PID Second Stage Output feature, you will need to choose upper and lower

limits for the PV, via C053 and C052 respectively. As the timing diagram below shows,

these are the thresholds Stage #1 inverter uses to turn ON or OFF Stage #2 inverter via

the [FBV] output. The vertical axis units are percent (%) for the PID setpoint, and for

the upper and lower limits. The output frequency, in Hz, is superimposed onto the same

diagram.

When the system control begins, the following events occur (in sequence in the timing

diagram):

1

. Stage #1 inverter turns ON via the [FW] Run command.

2

. Stage #1 inverter turns ON the [FBV] output, because the PV is below the PV low

limit C053. So, Stage #2 is assisting in loop error correction from the beginning.

3

. The PV rises and eventually exceeds the PV high limit C052. Stage #1 inverter then

turns OFF the [FBV] output to Stage #2, since the boost is no longer needed.

4

. When the PV begins decreasing, only Stage #1 is operating, and it is in the linear

control range. This region is where a properly configured system will operate most

often.

5

. The PV continues to decrease until it crosses under the PV low limit (apparent

external process disturbance). Stage #1 inverter turns ON the [FBV] output, and

Stage #2 inverter is assisting again.

6

. After the PV rises above the PV low limit, the [FW] Run command to Stage #1

inverter turns OFF (as in a system shutdown).

7

. Stage #1 inverter enters Stop Mode and automatically turns OFF the [FBV] output,

which causes Stage #2 inverter to also stop.

The terminal [FBV] configuration table is on the following page.

[FBV] to Stage #2 [FW]

0

1

t

0

1

Stage #1 [FW]

PV low limit

C053

PV high limit

C052

Events: 1,2 3 4 5 6 7

PID setpoint (SP)

%/Hz

PID feedback (PV)

Output frequency

448

Operations and

Monitoring

4 48

Operations and

Monitoring