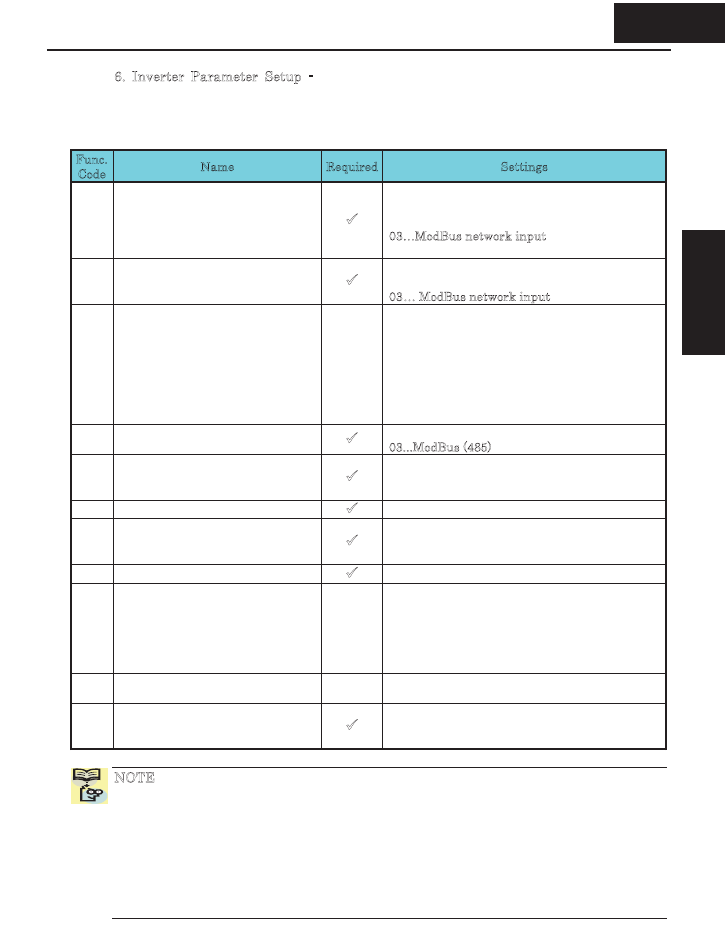

6. Inverter Parameter Setup - The inverter has several settings related to ModBus

communications. The table below lists them together. The

Required

column indicates

which parameters

must

be set properly to allow communications. You may need to

refer to the host computer documentation in order to match some of its settings.

Func.

Code

Name Required Settings

A001 Frequency source setting

9

00}Keypad potentiometer

01}Control terminal

02}Function F001 setting

0

3}ModBus network input

10}Calculate function output

A002 Run command source setting

9

01}Control terminal

02}Run key on keypad, or digital operator

0

3} ModBus network input

B089 Monitor display select for

networked inverter

01}Output frequency monitor

02}Output current monitor

03}Rotation direction monitor

04}Process variable (PV), PID feedback

monitor

05}Intelligent input terminal status

06}Intelligent output terminal status

07}Scaled output frequency monitor

C070 Selection of OPE/ModBus

9

02...OPE or option

0

3...ModBus (485)

C071 Communication speed selection

9

04}4800 bps

05}9600 bps

06}19200 bps

C072 Node allocation

9

Network address, range is 1 to 32

C074 Communication parity selection

9

00}No parity

01}Even parity

02}Odd parity

C075 Communication stop bit selection

9

Range is 1 to 2

C076 Communication error select

00}Trip (Error code E60)

01}Decelerate to a stop and trip (Error code

E60)

02}Disable

03}Free run stop (coasting)

04}Decelerate to a stop

C077 Communication error time-out

Comm. Watchdog timer period,

range is 0.00 to 99.99 sec.

C078 Communication wait time

9

Time the inverter waits after receiving a

message before it transmits.

Range is 0. to 1000. ms

NOTE: When you edit and store any of the parameters above, the inverter causes it to

take effect immediately. ModBus transmission occurs only after you set the OPE/485

DIP switch to the “485” position and turn on the inverter again. Note that parameters

C070 to C078 cannot be changed via the network. To edit them, you must disconnect the

inverter from the ModBus and wait for about 30sec until the inverter’s internal keypad

begin functioning. Then use this keypad to edit the parameters. Please don’t connect

other external programming devices to RJ45 connector, because the bus mode is in

RS485 mode. It may cause the inverter or external programming devices to be damaged

when DIP switch is in “485” position.

B5

Appendix B

B 5

Appendix B