CAUTION: Be careful to avoid specifying a braking time that is long enough to cause

motor overheating. If you use DC braking, we recommend using a motor with a built-in

thermistor, and wiring it to the inverter’s thermistor input (see “Thermistor Thermal

Protection” on page 4-24). Also refer to the motor manufacturer’s specifications for

duty-cycle recommendations during DC braking.

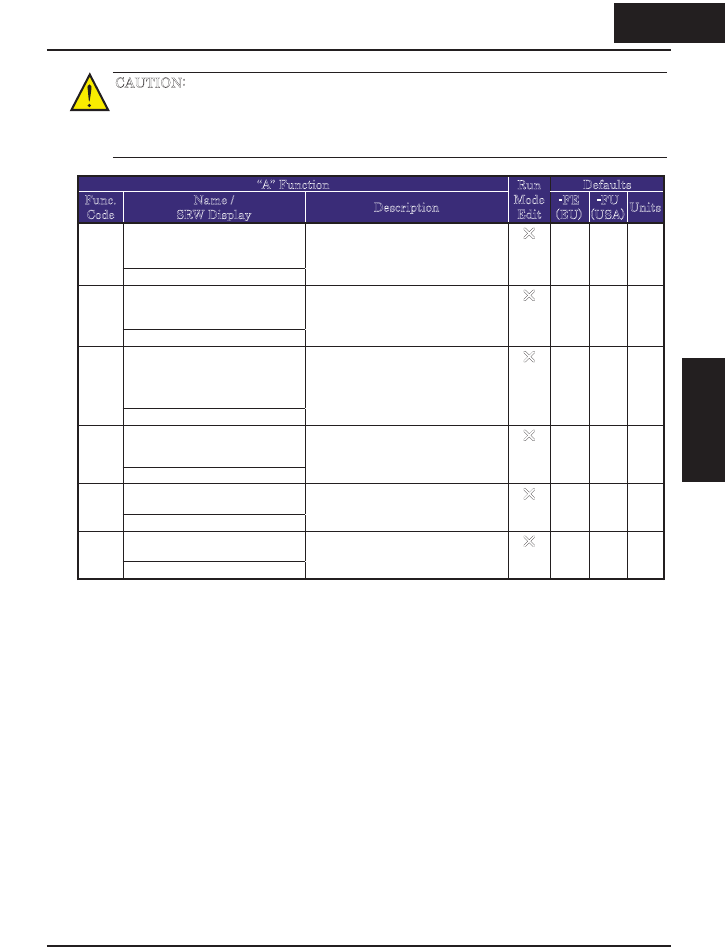

“A” Function Defaults

Func.

Code

Name /

SRW Display

Description

Run

Mode

Edit

-FE

(EU)

-FU

(USA)

Units

DC braking enableA051

DCB Mode OFF

Two options; select codes:

00}Disable

01}Enable during stop

02}Frequency detection

U

00 00

DC braking frequency settingA052

DCB F 0000.5Hz

The frequency at which DC

braking begins,

range is from the start frequency

(B082) to 60Hz

U

0.5 0.5 Hz

DC braking wait timeA053

DCB Wait 0000.0s

The delay from the end of

controlled deceleration to start of

DC braking (motor free runs

until DC braking begins),

range is 0.0 to 5.0 sec.

U

0.0 0.0 sec.

DC braking force for

deceleration

A054

DCB V 00000%

Level of DC braking force,

settable from 0 to 100%

U

0. 0. %

DC braking time for

deceleration

A055

DCB T 0000.0s

Sets the duration for DC braking,

range is from 0.0 to 60.0 seconds

U

0.0 0.0 sec.

DC braking / edge or level

detection for [DB] input

A056

DCB KIND LEVEL

Two options; select codes:

00}Edge detection

01}Level detection

U

01 01

319

Configuring Drive

Parameters

3 19

&RQ¿JXULQJ'ULYH

Parameters