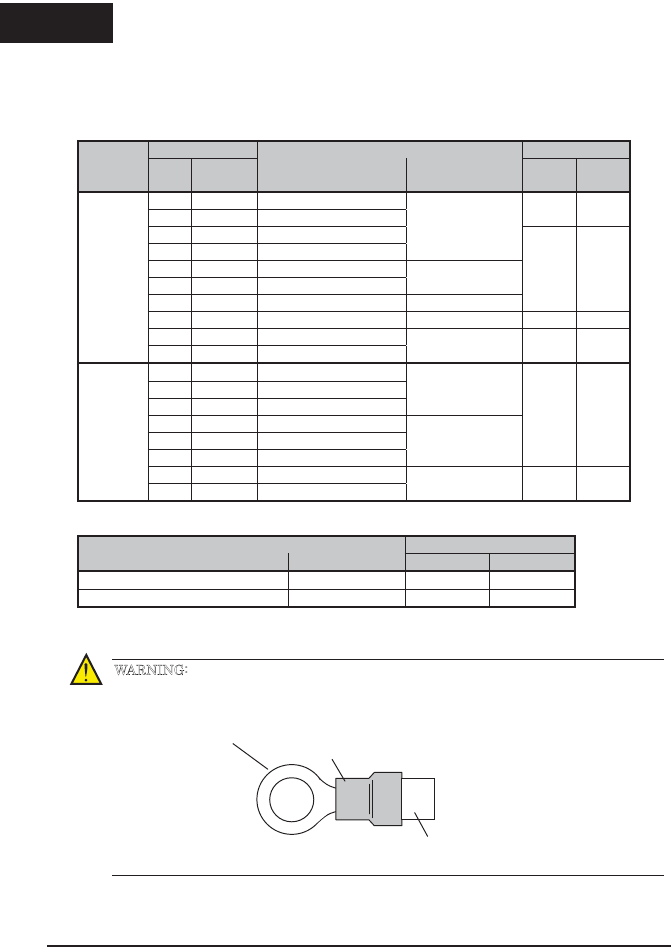

Terminal Tightening Torque and Wire Size

The wire size range and tightening torque for field wiring terminals are presented in

the tables below.

Motor Output Torque

Input

Voltage

kW HP

Inverter Model

Power Terminal

Wiring Size

Range (AWG)

Ft-lbs (N-m)

0.2 1/4 X200-002SFEF/NFU

0.4 1/2 X200-004SFEF/NFU

0.6 0.8

0.55 3/4 X200-005SFEF

0.75 1 X200-007SFEF/NFU

14

(75qC only)

1.1 1 1/2 X200-011SFEF

1.5 2 X200-015SFEF/NFU

12

2.2 3 X200-022SFEF/NFU 10

0.9 1.2

3.7 5 X200-037LFU 12 0.9 1.2

5.5 7 1/2 X200-055LFU

200V

Class

7.5 10 X200-075LFU

8 1.5 2.0

0.4 1/2 X200-004HFEF/HFU

0.75 1 X200-007HFEF/HFU

1.5 2 X200-015HFEF/HFU

16

(60qC only)

2.2 3 X200-022HFEF/HFU

3.0 4 X200-030HFEF

4.0 5 X200-040HFEF/HFU

14

(75qC only)

0.9 1.2

5.5 7 1/2 X200-055HFEF/HFU

400V

Class

7.5 10 X200-075HFEF/HFU

10 1.5 2.0

Torque

Terminal Connector

Wiring Size

Range (AWG)

Ft-lbs (N-m)

Logic and Analog connectors 30 – 16 0.16 – 0.19 0.22 – 0.25

Relay connector 30 – 14 0.37 – 0.44 0.5 – 0.6

Wire Connectors

WARNING: Field wiring connections must be made by a UL Listed and CSA certified

ring lug terminal connector sized for the wire gauge being used. The connector must be

fixed using the crimping tool specified by the connector manufacturer.

Terminal (ring lug)

Cable support

Cable

xiv

xiv