Receiving & Installation 3-13MN1854

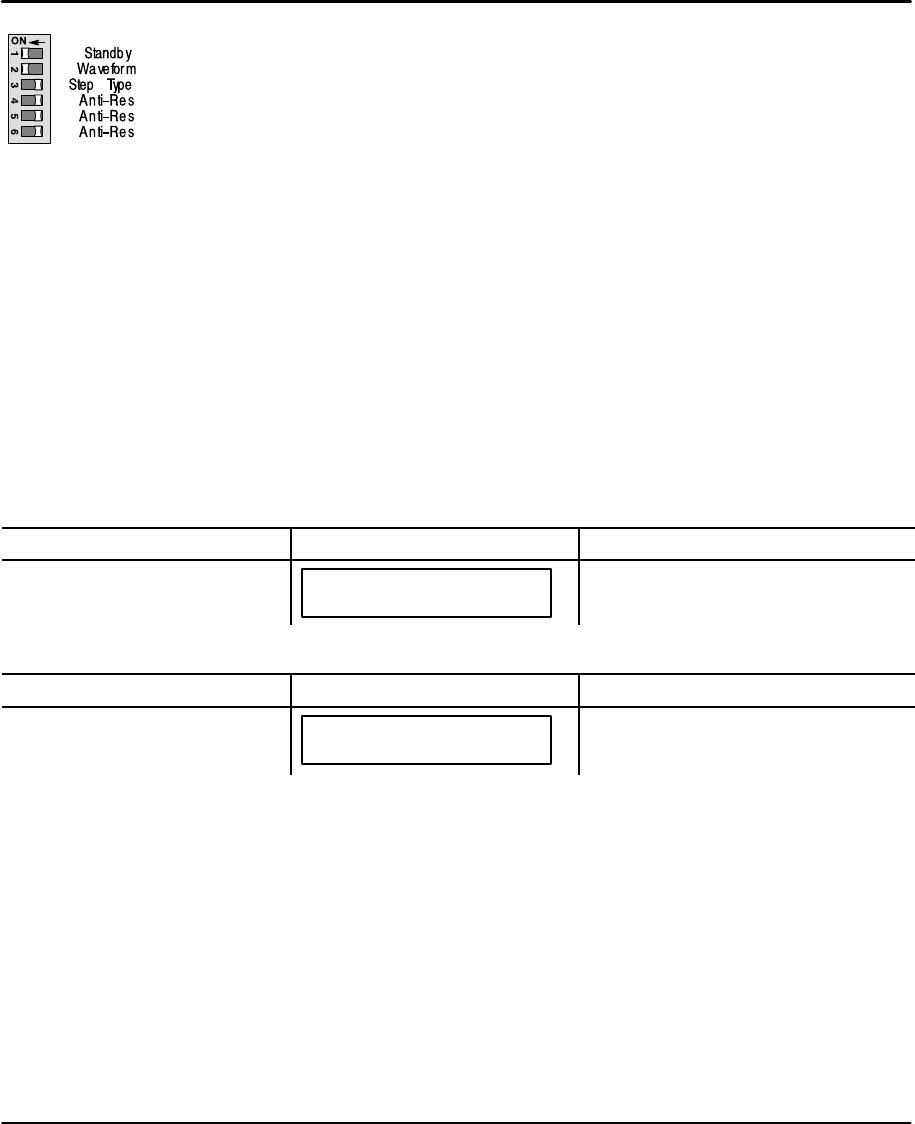

Standby Current (can be changed at any time)

Setting the Standby current DIP switch to ON reduces motor current by 30% when

the drive has not received a step pulse for 250 msec. Full current is restored when

the next step pulse is received. Each drive can also be set to standby with the EA2

software command.

A 30% reduction in motor current during Standby correlates with an approximate

30% reduction in motor holding torque. Do not use Standby mode in applications

where you need more than 70% of the motor’s torque to hold a load stationary.

Standby should not be used in applications where an encoder is used to perform

end–of–move position maintenance.

Waveform (can be changed at any time)

On Sinusoid, Off for 4% 3rd harmonic.

Step Type (can be changed at any time)

Not Used.

Anti–Res (can be changed at any time)

Not Used.

Power On Checks

When power is first applied, the “ON” LED will be green. With the keypad

connected, the LCD display will briefly display the initialization screens.

Note: The LCD display may require contrast adjustment for better viewing. If the

display cannot be seen, adjust the potentiometer in Figure 3-15 for best

viewing.

Action

Display Comments

Apply Power.

+0.0000

00000000 00000000

Power–up diagnostic display. No errors.

The motor should now be producing torque.

Action

Display Comments

Select “RUN, JOG (F2)”.

JOG AXIS +0.0000

<LO> HIGH

Select either Low or High to Jog the

motor position. Confirm proper motor

operation.