7-2 Troubleshooting MN1854

Additional Information Continued

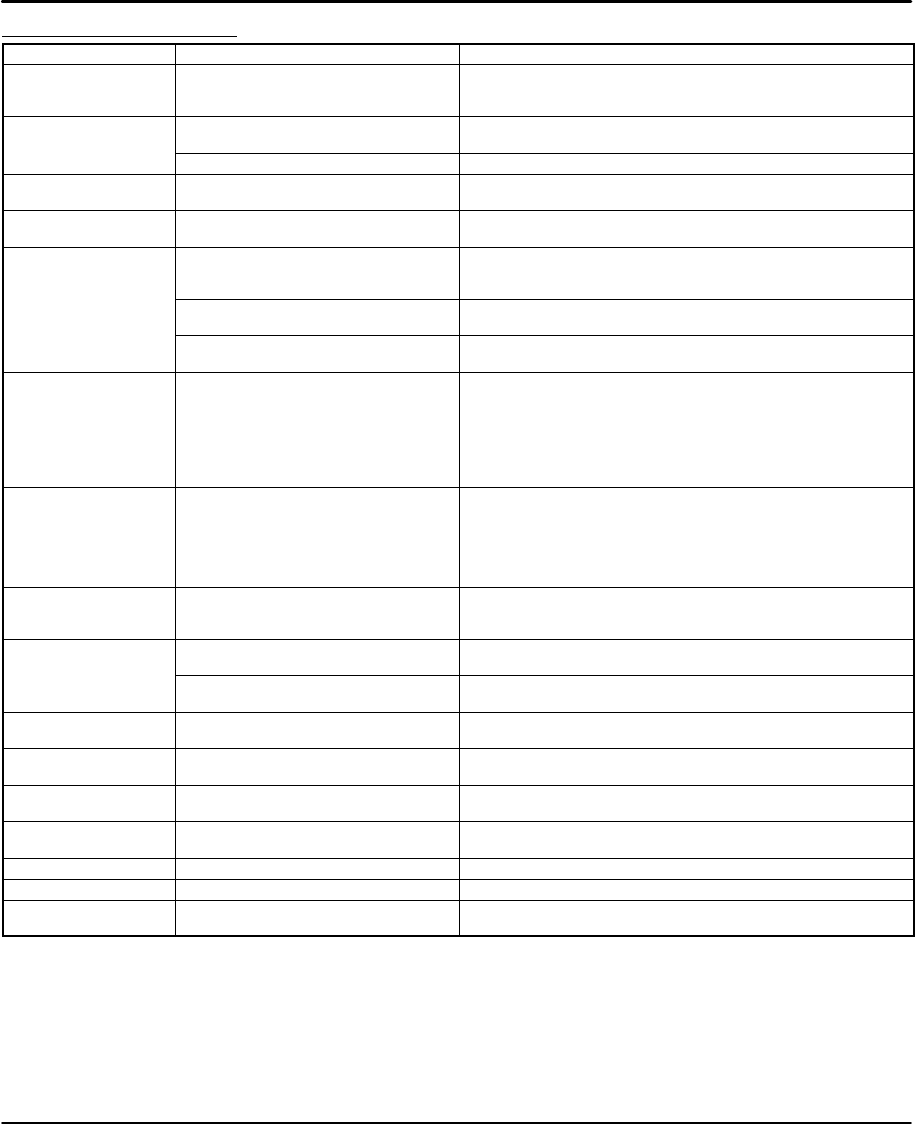

Symptom Possible Cause Possible Remedies

No RS232 commu-

nication but keypad

works.

If the keypad works, the RS232 port

is working. Something else is wrong

(wiring, configuration, address).

Refer to Section 5, “Configure Serial Communications”.

Verify PC COM port is set to 9600 baud, 8 data bits 1 stop bit,

no parity.

RS232 communica-

tion and keypad do

The keypad is disabled. Verify that you do not have an RS485 version.

Enable the keypad by the switch on back of keypad.

tion and keypad do

not work.

The serial port is not working. Contact Baldor.

“Hit A Limit” A limit switch has been activated. Either the motion commanded was not correct, or the EOT

switch is incorrectly positioned on your system.

“Amplifier Fault” Multiple drive faults have occurred. The fault can be determined with the keypad or by using serial

status commands (SS, SA, SD).

“Over Temperature

Fault”

Internal Fan is not operating or

Heatsink Tunnel is clogged or

restricted.

Remove obstruction, or clean tunnel by removing unit, use

screwdriver to prevent the fan from turning, and blow shop

air through the tunnel. Return unit to installation.

Ambient air in cabinet is too hot. If multiple units are installed within the enclosure, ventilation

must be adequately to remove heat.

The fan does not operate. With power off, verify the internal fan connections. If properly

connected, the fan may have failed. Contact Baldor.

“Over Current Fault” Motor is miswired or damaged. The

LinStep+ has short circuit protection,

but you must correct the problem to

clear the fault.

With power off verify all connections.

Verify current setting is correct for the motor rating.

Verify the motor phases are not open or shorted (phase to

phase and phase to ground). The resistance in each phase

should be about the same and only a few ohms. If the

phases are open or have a large resistance, the motor is

probably damaged and should be replaced.

“Over Voltage Fault” Excessive bus voltage. Usually

caused by a regen condition that

overwhelms the internal power

dump circuit.

It can also be caused by high line

voltage, or voltage spikes.

Eliminate the regen event by reducing the load or make the

move less aggressively by reducing the commanded

acceleration or velocity.

Verify AC line voltage is within the limits.

“Interlock Fault” Motor connector does not have an

interlock jumper, or motor has been

disconnected.

Connect motor connector with Interlock.

“Following Error” Motor stalled. Confirm proper motor configuration (current, AR, mH).

Make a less aggressive move.

Wrong encoder resolution set. Verify the encoder settings are correct. Incorrect settings can

cause a following error.

“Encoder Wired

Backwards”

Encoder position is changing opposite

the commanded move.

Verify motor and encoder wiring. Reverse phases of either

motor or encoder. Contact Baldor for assistance.

“Encoder Fault” Attempted closed loop motion and

encoder position is unchanged.

Verify encoder wiring.

“Error Finding Home” Both EOT switches were activated

without finding the home switch.

Verify home switch connections and configuration (NORM

OPEN or NORM CLOSED).

“Invalid Program” Attempted to “call” an empty program

(i.e. GT, GS).

Verify program number, or define program “called”.

“Program Too Large” Program length exceeds 1024 bytes. Divide program into smaller programs or reduce program size.

“Insufficient Memory” All stored user programs exceed 60K. Reduce program size, or delete programs.

“Invalid Program #” Program number exceeds 400 or

program name does not exist.

Verify program name and number.