3 Controller

RT ToolBox2/RT ToolBox2 mini

3-126

(7) RT ToolBox2/RT ToolBox2 mini

■Order type : ●RT ToolBox2

*For windows CD-ROM : 3D-11C-WINE

●

RT ToolBox2 mini

*For windows CD-ROM : 3D-12C-WINE

■ Outline

This is handy software that fully uses the personal computer functions. It can be used in

various stages from the robot specifications study (tact study, etc.) to the design support

(creation and editing of programs), start up support (execution, control and debugging of

program), and maintenance.

The "personal computer support software" which supports these function fully, and the

"personal computer support software mini" which does not have the simulation function

are available.

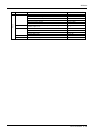

■ Configuration

Table 3-36 : Product configuration

■ Features

(1) Simple operation with guidance method and menu method

The Windows standard is used for windows operation, so the controller initialization and startup operations

can be carried out easily by following the instructions given on the screen. Even a beginner can easily carry

out the series of operations from program creation to execution.

(2) Increased work efficiency with ample support functions

The work efficiency is greatly improved with the multi-window method that carries out multiple steps and dis

-

plays in parallel. The renumbering function, and copy, search, syntax check and step execution are especially

sufficient, and are extremely useful when editing or debugging the program.

With the simulation function support, the program can be debugged and the tact checked before starting the

machine at the site. This allows the on-site startup work efficiently to be greatly improved.

(3) The maintenance forecast function increases the efficiency of maintenance work. Analyze the load condition

while the robot is actually operating. Based on this analysis, calculate the time for maintenance, such as lubri

-

cation and belt replacement. By utilizing this information, the line stop time as well as the maintenance costs

can be reduced.

(4) The position recovery support function increases the recovery efficiency in the event of origin position dis

-

placement. This function compensates the origin settings and position data by just reproducing several previ-

ous teaching points when hand and/or arm displacement occurs, when replacing the motor and the belts, or

when reloading the robot. This function can reduce the time required for recovery.

Part name Type Medium

Mass (kg)

Note1)

Note1) Mass indicates one set.

Remarks

RT ToolBox2 3D-11C-WINE CD-ROM 0.2

RT ToolBox2 mini 3D-12C-WINE CD-ROM 0.2