1-5

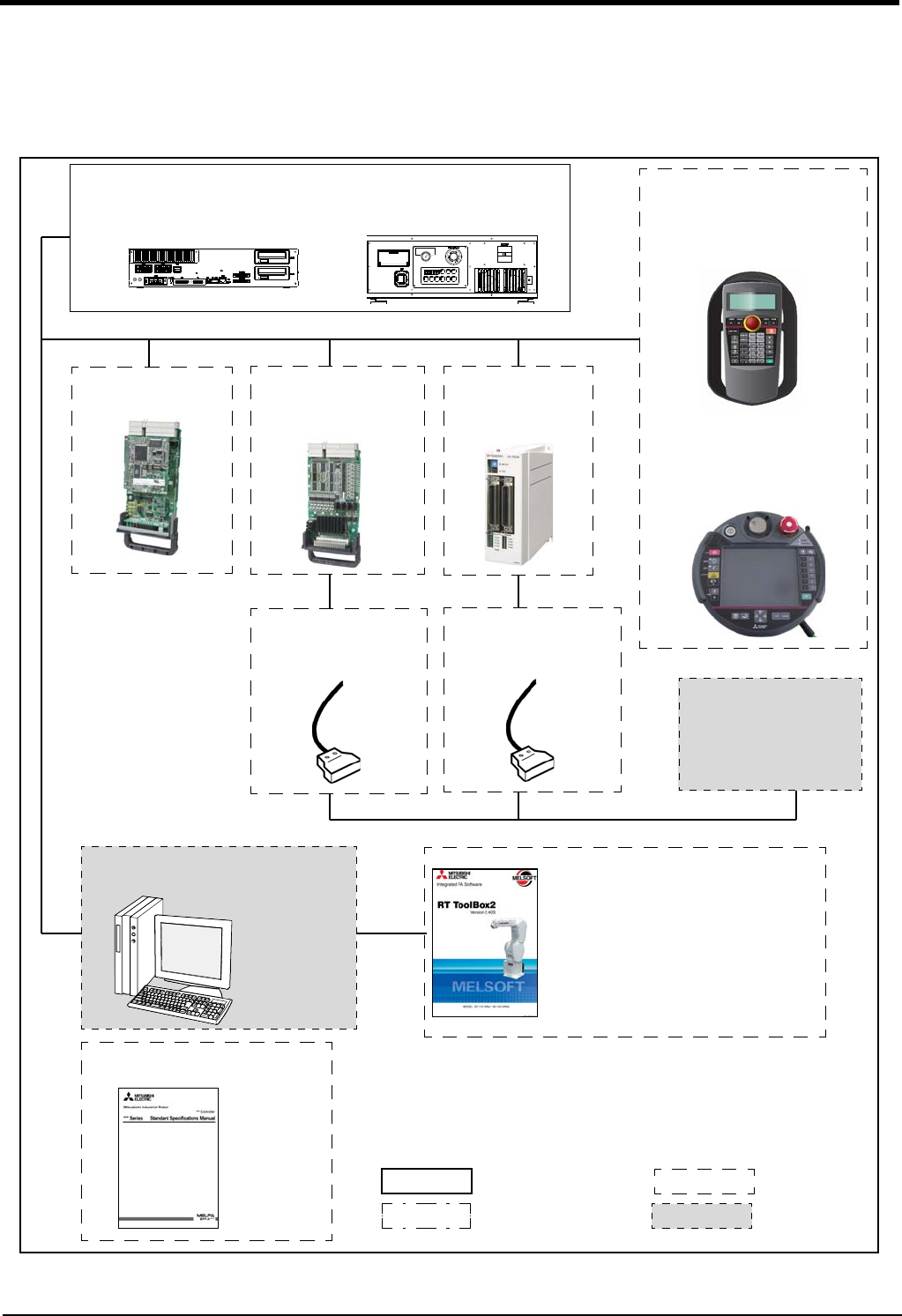

1 General configuration

1.6.2 Controller

The devices shown below can be installed on the controller.

The controllers that can be connected differ depending on the specification of the robot. (Refer to Page 2, "1.2

Model type name of robot".)

Fig.1-2 : Structural equipment

Personal computer

Prepared by customer

*)Refer to Table

1-5 for USB

cable

Instruction Manual (bookbinding)

・ 5F-FA01-PE01

Parallel I/O interface

2D-TZ368(Sink)/

2D-TZ378(Source)

CC-Link interface

2D-TZ576

Teaching pendant (T/B)

Simple T/B

・ R32TB: For CR750 controller

・ R33TB: For CR751 controller

Highly efficient T/B

・ R56TB: For CR750 controller

・ R57TB: For CR751 controller

Controller

・ CR751-03HD-0

・ CR751-03HD1-0-S15

・ CR750-03HD1-1-S15

External I/O cable

・ 2D-CBL05 (5m)

・ 2D-CBL15 (15m)

Parallel I/O unit

2A-RZ361(Sink)/

2A-RZ371(Source)

External I/O cable

・ 2A-CBL05 (5m)

・ 2A-CBL15 (15m)

RT ToolBox2/RT ToolBox2 mini

RT ToolBox2

・ 3D-11C-WINE(CD-ROM)

(Windows XP、 Windows Vista、 Windows 7、

Windows 8、 Windows 8.1)

RT ToolBox2 mini

・ 3D-12C-WINE(CD-ROM)

(Windows XP、 Windows Vista、 Windows 7、

Windows 8、 Windows 8.1)

PLC (Programmable

Logic Controller)

External device

Prepared by customer

Standard configuration

Special specifications

Options

Prepared by

[Caution]

equipment

customer