2 Robot arm

2-20

2.2.7 Protection specifications

(1) Types of protection specifications

The robot arm has protection specifications that comply with the IEC Standards. The protection specifications

and applicable fields are shown in Table 2-6.

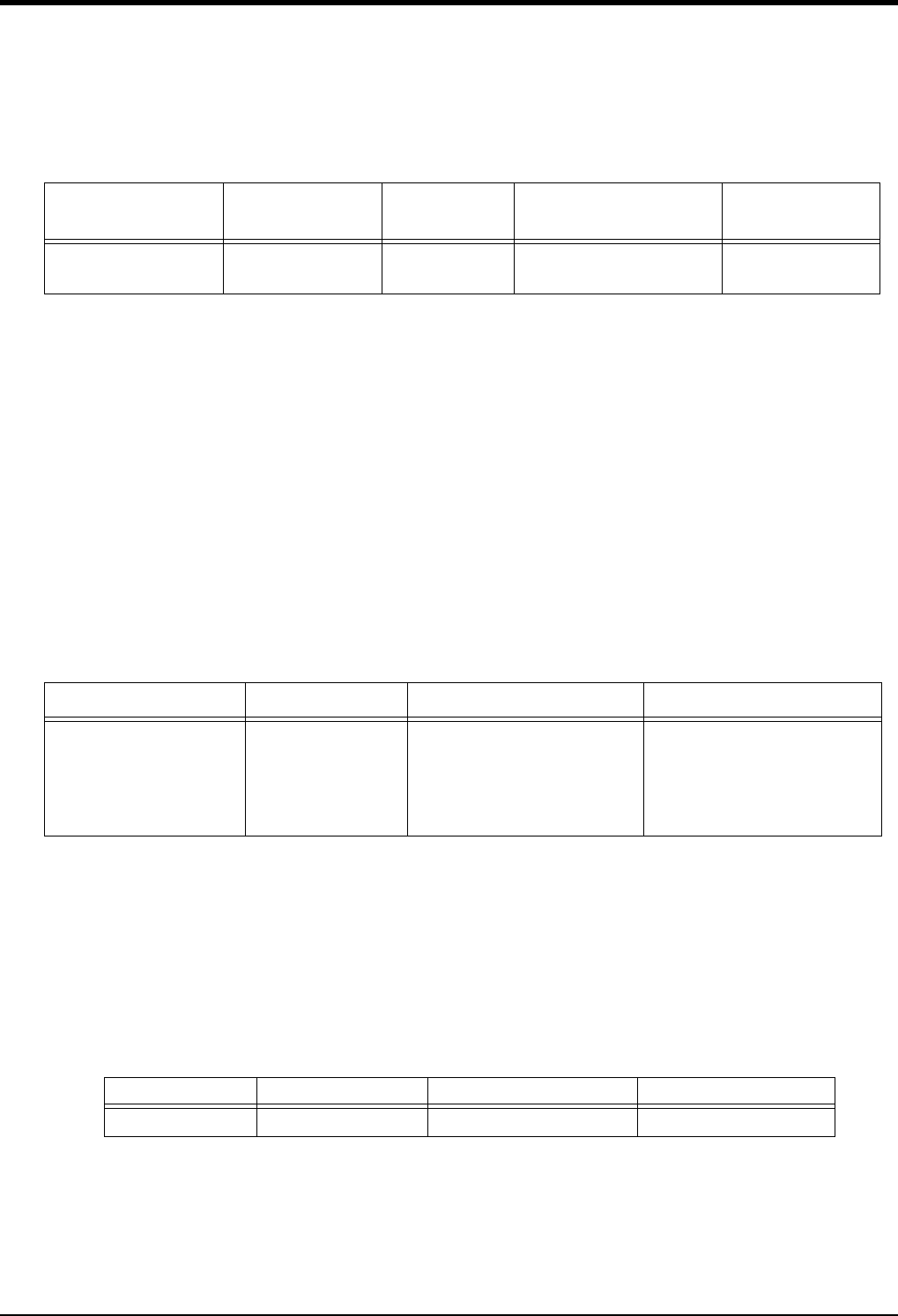

Table 2-6 : Protection specifications and applicable fields

The IEC IP symbols define the degree of protection against solids and fluids, and do not indicate a protective

structure against the entry of oil.

The IEC standard is described by the following "Information" And, the corrosion of the rust etc. may occur to the

robot with the liquids.

【Information】

・ The IEC IP20

It indicates the protective structure that prevents an iron ball 12

0

+0.05

mm diameter, which is being pressed

with the power of 3.1 kg±10%, from going through the opening in the outer sheath of the supplied equipment.

2.2.8 Clean specifications

(1) Types of clean specifications

The robot arm with clean specification is made by order. Please check the delivery schedule.

Table 2-7 : Clean specifications

■ Precautions for use

1) A φ8 VACUUM coupling is provided in the base section of the robot arm for vacuum inside the robot arm.

(Refer to Fig. 2-23) When using the robot, connect this coupling with the vacuum generating valve (Refer to

Table 2-8) and vacuum pump (furnished by the customer).

2) To suck in the robot arm, use the vacuum generator of the specification shown in following a) and b).

a) When using the vacuum generator

Table 2-8 : Specifications of vacuum generation valve (Confirmed in our company)

b) When using the vacuum pump

Assure the vacuum flow rate of 30-50L/min. And, secure the exhaust course from the pump not to affect

the power supply and the cleanness for the vacuum pumps.

Type

Protection

specifications

(IEC Standards value)

Classification Applicable field Remarks

RH-3FHxx15

Robot arm: IP20

General-purpose

environment speci-

fications

General assembly

Slightly dusty environment

Type Degree of cleanliness Internal suction Remarks

RH-3FHxx12C

ISO class 3

Note1)

Note1) The conditions necessary to guarantee cleanliness are as follows: clean room down flow greater then 0.3 m/s,

robot internal suction of 30 to 50 L/min, and installation of an exhaust duct at the rear of the robot’s main base. A

φ8 joint has been prepared at the rear of the base for suction.

・ Suck the inside of robot arm with

vacuum pump. (prepared by cus-

tomer)

・ Use it in the clean room with the

down flow (flow velocity 0.3 m/s

above).

The use of a vacuum generating valve

is recommended.

Type Maker

Air pressure

Note1)

Note1) It is the vacuum pump maker's written specification.

Quantity

MEDT 14 KOGANEI CORPORATION ・ Vacuum rate: 90.0 L/min(ANR)

1