3-85

Emergency stop input and output etc.

3 Controller

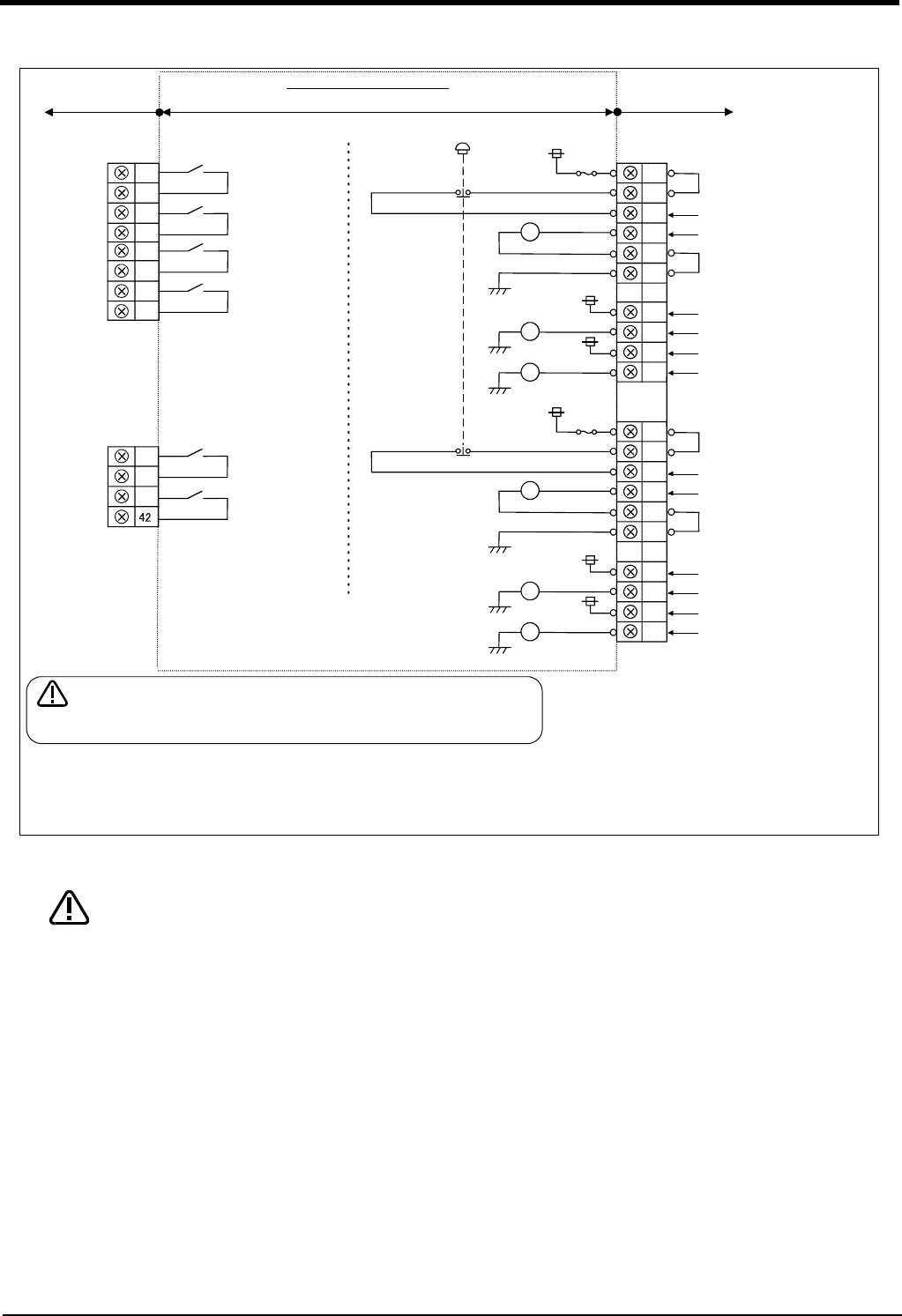

Fig.3-14 : External emergency stop connection (CR751)

Place the emergency stop switch in an easily operable position, and be sure to wire it

to the emergency stop correctly by referencing Page 139, "6.1.7 Examples of safety

measures".

This is a necessary measure in order to ensure safe operation so that the robot can be

stopped immediately by pressing the emergency stop switch in the event that the

robot malfunctions.

CNUSR1

CNUSR2

内部回路構成

(お客様配線側)

(コントローラ側)

警告

絶縁耐圧試験は行なわないでください。

また誤って接続した場合は故障の原因となります。

CNUSR1

+24V

Relay

+24V

24G

24G

24G

RA

+24V

Relay

RA

Relay

RA

外部非常停止入力

ドアスイッチ入力

イネーブリング

デバイス入力

TB

非常停止

+24V

Relay

+24V

24G

24G

24G

RA

+24V

Relay

RA

Relay

RA

43

18

17

41

16

モード出力

非常停止出力

ロボットエラー出力

外部非常停止入力

ドアスイッチ入力

イネーブリング

デバイス入力

(お客様配線側)

短絡

短絡

短絡

短絡

モード出力

非常停止出力

ロボットエラー出力

44

19

42

17

20

45

27

28

4

29

5

30

3

2

1

26

32

33

9

34

35

8

7

6

31

10

Please refer to the example of safety measures

of "Standard Specifications Manual".

Please do not carry out an insulation pressure test.

Moreover, it becomes the cause of failure if it

connects incorrectly.

CAUTION

Internal circuit structure

(Controller side)

(Customer)

Mode output

Mode output

Robot error

output

Robot error

output

Emergency

stop output

Emergency

stop output

Short

External emergency

stop input

Short

Door switch input

Enabling device

input

Short

External emergency

stop input

Short

Door switch input

Enabling device

input

TB emergency stop

(Customer)

*1) This terminal is opened at factory shipping (unconnected). If power supply inside the controller is used, short-circuit the terminal.

*1)

*1)

*1)

*1)

[Note] In the customer's system, do not ground the + side of 24V power supply prepared by customer for connect to the con

-

troller. (related with emergency stop and parallel input/output) If it connects with the controller under the condition that

the + side is grounded, it will lead to failure of controller.

CAUTION