6Safety

Safety

6-140

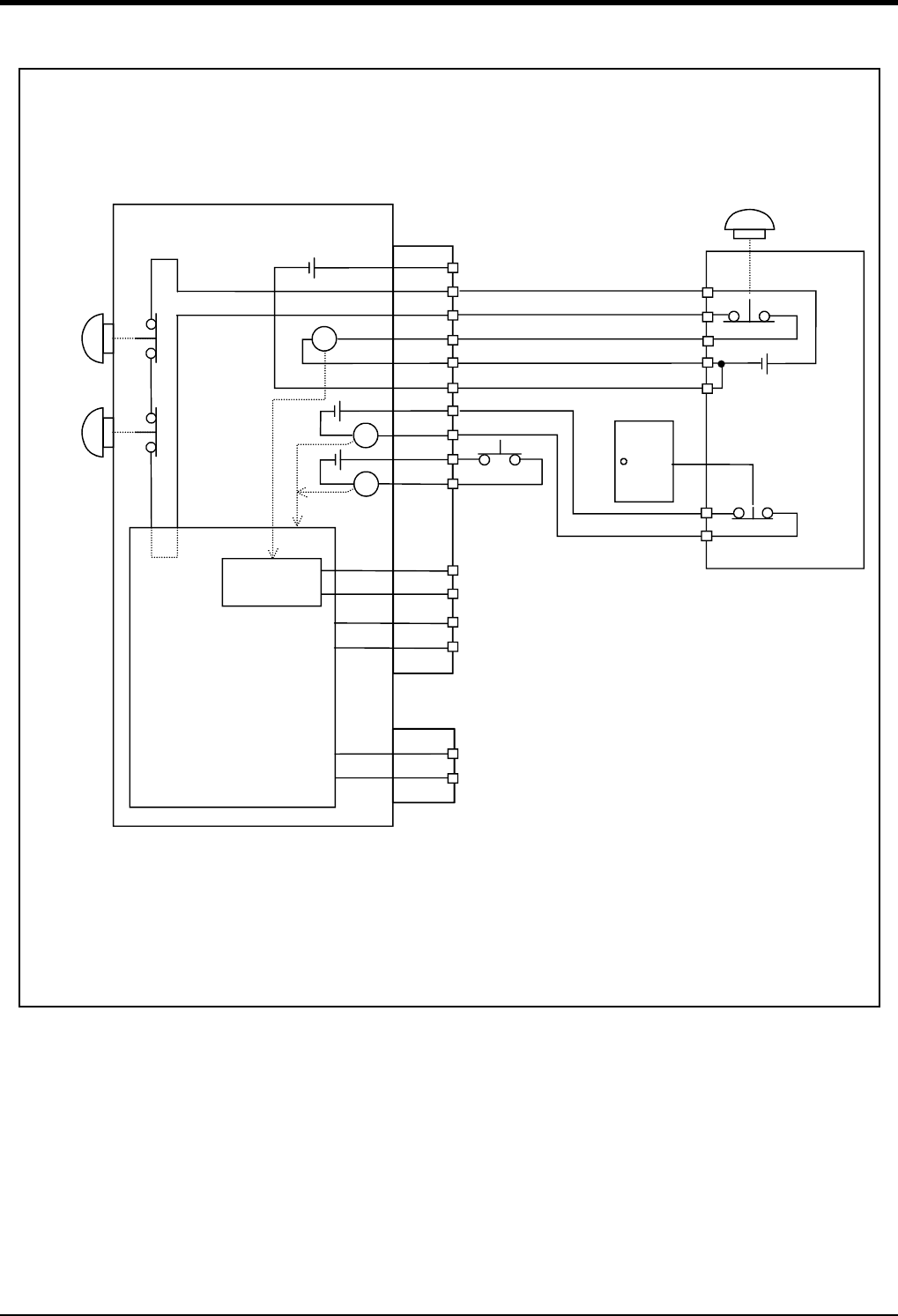

Fig.6-2 : Example of safety measures (CR750 wiring example 2)

非常停止スイッチ

(2接点タイプ)

周辺装置

安全柵のドア

周辺装置側電源

24V

CNUSR2

内部非常停止回路

未接続

非常停止出力

モード出力

RA

RA

RA

}

ドアスイッチ入力

イネーブリング

デバイス

16/17

41/42

エラー出力

}

}

1

CNUSR11/CNUSR12

2

3

4

5

6

7

8

9

10

13

14

11

12

OP非常停止

ボタン

TB非常停止

ボタン

内部電源 24V

安全リレー

*1) Each of the connectors,

CNUSR11 and CNUSR12, are

assigned with the same pin

number, creating 2 systems in

each terminal. It is absolutely

necessary to connect the 2

systems.

*2) You can see in the diagram that

connector CNUSR2 has 2

terminals and 2 systems (16/17

indicates 2 terminals at pin

number 16 and pin number 17).

It is absolutely necessary to

connect the 2 systems.

<Wiring example 2>: Connect the emergency stop switch of peripheral equipment to the controller.

The power supply for emergency stop input uses the power supply of peripheral equipment.

<Operation of the emergency stop>

If the emergency stop switch of peripheral equipment is pushed, the robot will also be in the emergency

stop state.

Controller

*3) The T/B emergency stop button connected with the controller.

*4) Emergency stop input relay.

*5)

Refer to the Standard specification manual or the Special specification manual for the enabling device.

*6) The emergency stop button of the robot controller.

(Only specification with the operation panel.)

*7) The emergency stop input detection relay uses the controller’s internal safety relay control. If the

emergency stop input detection relay is switched OFF, emergency stop is detected and the safety relay

is also switched OFF.

Power supply in the

robot controller 24V

OP Emergency

stop button

TB Emergency

stop button

Not connected

Door switch input

Enabling

device

Mode output

Error output

Emergency stop output

Safety relay

Internal emergency stop

circuit

Emergency stop switch

(2- contact type)

Peripheral

equipment

Safety

fence door

Power supply in

the Peripheral

equipment 24V

*1)

*2)

*3)

*6)

*4)

*5)

*7)