Specifications, Applications,

Service Instructions & Parts

HANSEN TECHNOLOGIES

CORPORATION

Bulletin C401d

March, 2002

Flanged

3

/8" thru 4"

FPT, SW, WN, ODS

for refrigerants

HCK4-4 Check Valve

INTRODUCTION

The HCK4 series of dependable, compact, rugged

in-line check valves (disc type non-return valves) is

ideally suited for refrigerant flow control applications.

Valves open wide for flow in the arrow direction on

the valve body. Valves close quickly and

reliably when flow reversals occur.

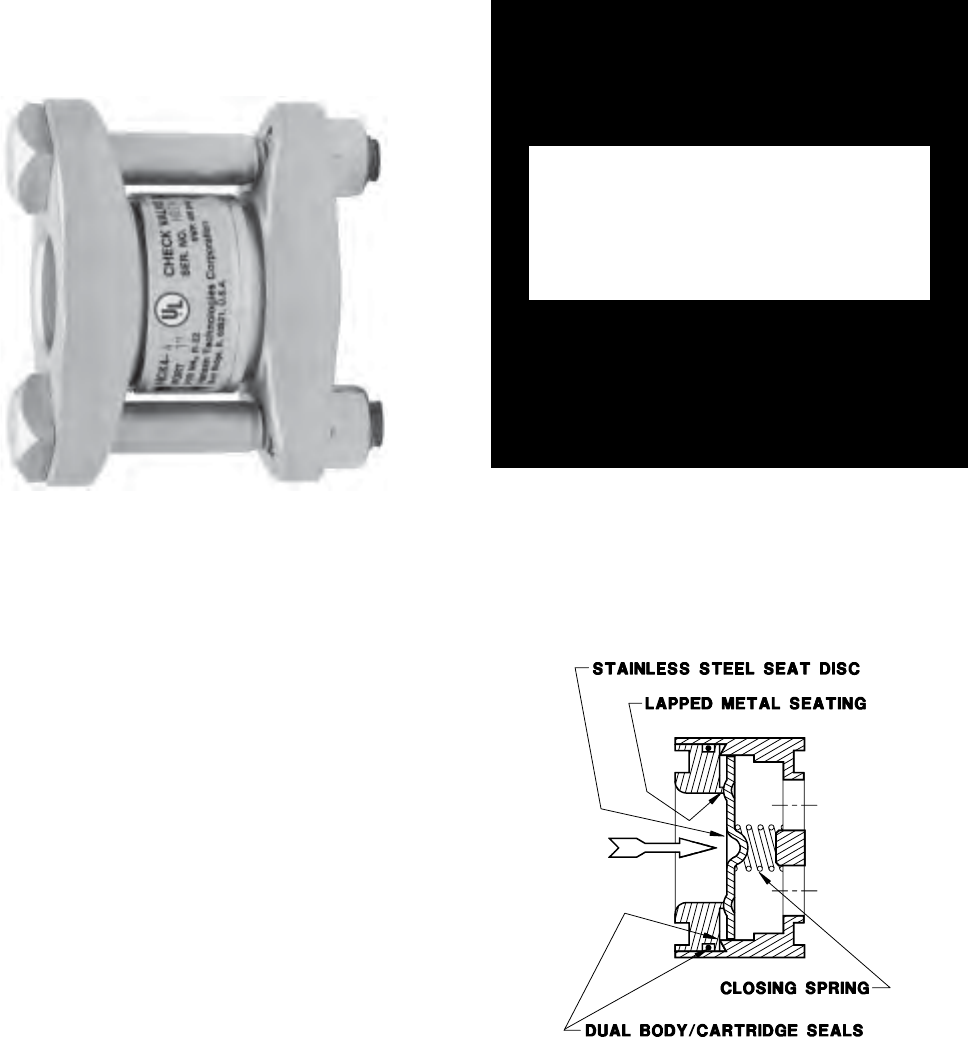

Plated bodies and stainless steel seat discs and

springs enable them to withstand expected

industrial refrigeration conditions. Furthermore, these

check valves can be mounted in any position, close-

coupled to other valves, and use same flanges as

Parker R/S, Frick, and Henry.

ADVANTAGES

These compact check valves offer reliable operation

regardless of position. Corrosion resistant stainless

steel seat disc. Metal-to-metal seats facilitate durable,

tight closing of valves.

APPLICATIONS

These in-line check valves are designed to provide

refrigerant flow control to hot gas lines, liquid lines,

compressor discharge lines, suction lines, and hot

gas heated drain pans.

These valves are not recommended for use with

pulsating loads such as low speed compressor

discharge and screw compressor side port

applications. For applications such as these, use

Hansen HCK1 piston type check valves.

ADDITIONAL FEATURES

Mounts in any position

Less than 1 PSID wide opening pressure

Can be close-coupled

Low bubble leakage tolerance

For Ammonia, R22, R134a, and other approved

refrigerants

Dimensionally replaces R/S CK4A-2, -3, -4, -8, & -1

U.L. Listed

KEY FEATURES

HCK4 IN-LINE

CHECK VALVES

5

/8" thru 4" PORT

(16 thru 100 mm)