VILTER MANUFACTURING CORPORATION

VILTER MultiCylinder Compressor

400 Series VMC 2/01

SERVICE - 16 - Replaces all Previous Issues

3. Unloader Piston Replacement

Before reinstalling piston, remove old ring

set. Clean and inspect for wear. Replace

piston if wear is excessive. a ring set con-

sisting of “PTFE” outer ring and a silicone

rubber inner ring is used on the piston. Re-

place ring set carefully with a new one every

time a piston is removed. With eyebolt re-

moved, place the piston into its hole in the

frame. Compress the rings with the fingers

and work them into the hole carefully so they

are not nicked or cut as the piston is moved

down. Push the piston down until it touches

the yoke lifting arm.

4. Actuator Mechanism Removal

Before a capacity control actuator mecha-

nism can be removed from the compressor,

at least one of its corresponding cylinder lin-

ers must be removed. The first step in re-

moving capacity control actuator from the

machine is to push the unloader piston down

with a block of wood. Then take a piece of

steel (

5

/

16

” in diameter) or a piece of wood,

and insert it between the two vertical rods on

the yoke assembly accommodating the short

pivot pin and fulcrum pin. This will hold the

assembly depressed and make handling

much easier. Then remove the unloader pis-

ton as detailed above. The mechanism can

then be removed through the cylinder liner

hole in the frame.

5. Actuator Mechanism Replacement

Compress the yoke assembly and place a

small piece of wood or a

5

/

16

” (7.94 mm) o.d.

steel rod between the two vertical rods men-

tioned in paragraph 4. This keeps the yoke

depressed for easier handling. Then place

the mechanism into the frame through the

cylinder liner opening and position it. Install

unloader piston as detailed above. Depress

the unloader piston with a block of wood and

remove the rod or piece of wood used to

hold the yoke assembly depressed. Then

center the mechanism between the two cyl-

inder liner holes.

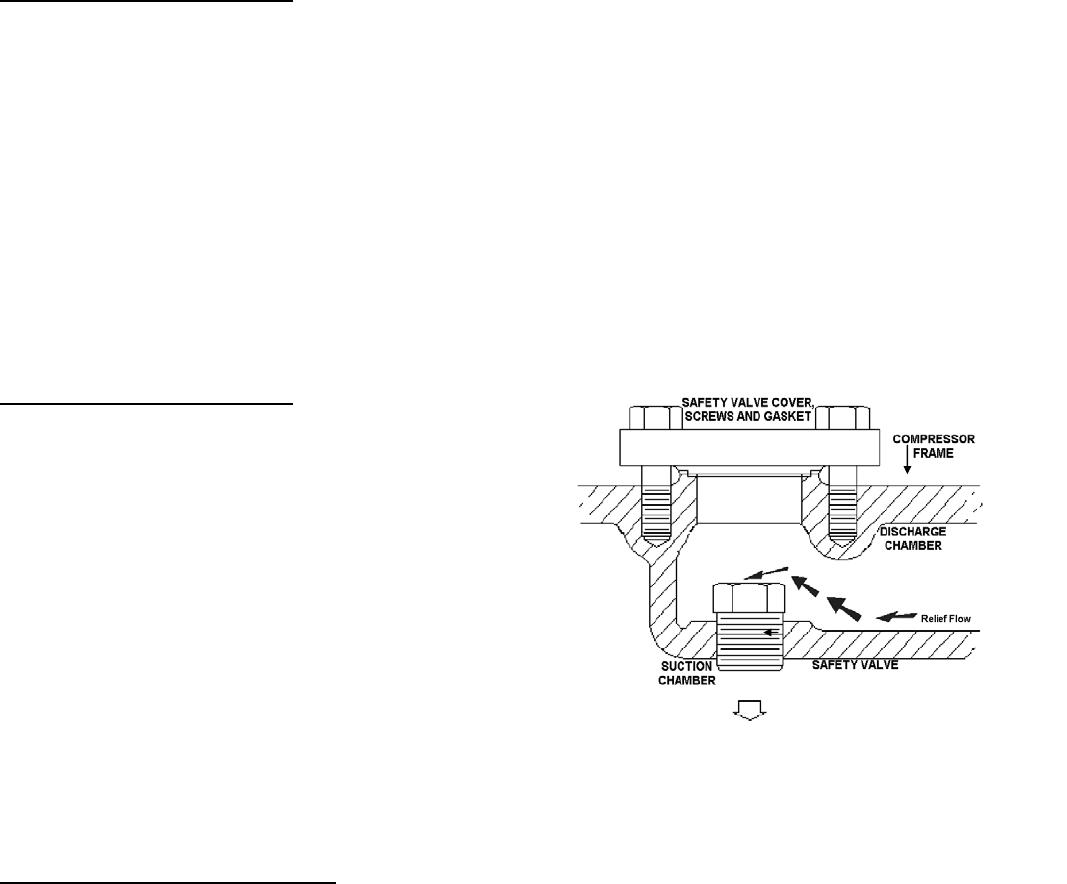

VI. SAFETY VALVE (INTERNAL RELIEF)

A. Removal

If, for any reason, the safety valve has relieved,

install a new valve. Make no attempt to adjust

the relief valve. To replace the safety valve, re-

move the cover on the top of the compressor

frame marked “safety valve” by taking out the two

screws which hold it in place. Then, remove the

safety valve by using a standard 1¾” (44.45 mm)

socket.

Note: Safety Valve is set at a differential pressure of 300

PSIG (2069 kPa). Maximum discharge temperature is

300°F (150°C).

FIGURE 9. SAFETY VALVE LOCATION

B. Replacement

Lightly oil the threads of the valve and screw the

valve into place. Lightly oil a new gasket and

place it on the frame. Position the cover and

tighten it down.