VILTER MANUFACTURING CORPORATION

VILTER MultiCylinder Compressor

400 Series VMC 2/01

SERVICE - 9 - Replaces all Previous Issues

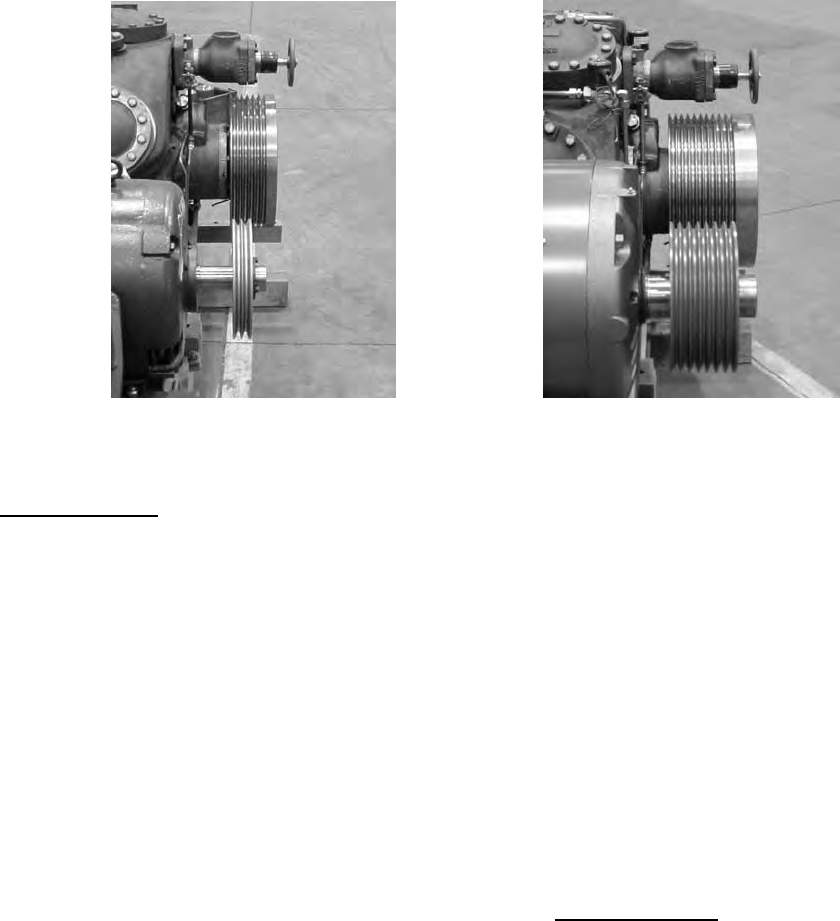

456XL Booster 458XL High Stage

FIGURE 5. UNIT BELTING REQUIREMENTS DUE TO HORSEPOWER

4. Drive Inspection

(cont’d)

The groove bottom should also be checked

for polishing, as this indicates the belt is not

riding correctly in the groove. What has

happened is the belt or groove has worn to

the point the belt is actually rubbing on the

bottom of the groove. This effectively

changes the pitch diameter of the sheave or

pulley for that groove, causing the belt to

operate at a different speed than the rest.

This will result in excessive heat and wear to

the drive components.

When drive components are replaced, it is

necessary to replace them with identical

components. Due to operating conditions

and the horsepower requirements of the

compressors, the number of belts on a com-

pressor package can vary from 2 through 10

belts and not all flywheel grooves will be

filled.

Drive belts should be inspected for abrasion,

tearing, separation or checking that would

indicate possible damage to drive compo-

nents or alignment problems. They should

also be inspected for sharp bends and kinks

while they are slack as this indicates internal

damage due to incorrect installation tech-

niques. The belts can be cleaned at this

time. Only soap and water should be used

to clean the belts and other components.

Belt dressing should never be used on drive

components, as it will attack the elastomer

used in construction of the belts.

Belts should always be changed in sets to

minimize length variations between used and

new belts. Note the match numbers on the

belts. The same number must be on all belts

in the set.

5. Drive Installation

If installation is new and the belts are being

installed for the first time, the following items

must be taken care of before the belts can

be installed.