VILTER MANUFACTURING CORPORATION

VILTER MultiCylinder Compressor

400 Series VMC 2/01

SERVICE - 3 - Replaces all Previous Issues

A. Disassembly (cont’d)

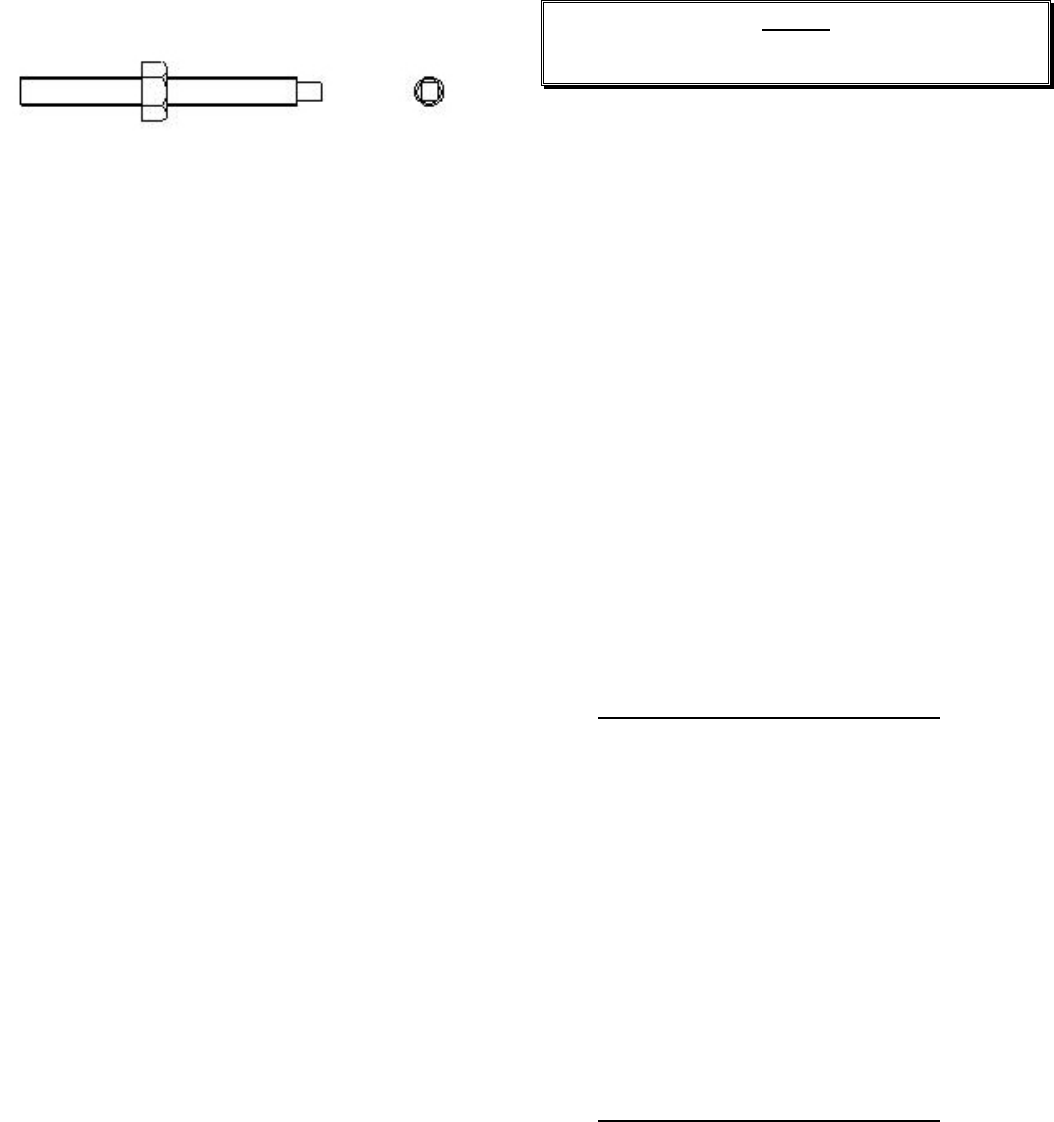

FIGURE 1. BEARING AND CYLINDER

COVERS ASSEMBLY & DISASSEMBLY STUD

B. Assembly

Before replacing the cover on the compressor,

inspect the gasket surfaces of the cover and

compressor frame. Remove any debris adhering

to either of these surfaces. Remove any burrs or

rough edges from the mating surfaces to ensure

a tight seal. Replace studs, if removed. Lightly

lubricate both sides of the head gasket. Position

the gasket over the studs and against the com-

pressor frame in the correct orientation. Place

the springs on top of the safety head yokes (ro-

tating the spring until it stays on the yoke). Place

the cover down over the studs and slowly lower

on top of springs. When all pieces are in align-

ment, place the nuts on the studs and start to

tighten. When the cover is secure within 1¼”

(31.75 mm) of the gasket, install the rest of the

screws so they come in contact with the cover.

This will ensure they will not cross thread in the

holes.

Do not tighten each screw separately, however.

Alternate on opposing screws, until the cover is

seated on the gasket. Remove the studs and

replace with screws. Finish tightening the screws

in an opposing pattern to the recommended

torque values shown in Table 2, 3 or 4 (depend-

ing upon your compressor model). Reinstall the

capacity control and head cooling lines, and

check for leaks.

III. SUCTION AND DISCHARGE VALVE PLATES

NOTE:

Before proceeding, refer to Paragraph I, “General

Service Instructions”.

A. Disassembly

To service valve plates in the compressor, re-

move the cylinder covers (refer to paragraph

II.A). In cylinders without unloaders, the valve

assemblies may be removed as soon as the cov-

ers are removed.

On compressor cylinders equipped with unload-

ers, the unloader needs to be forced down before

the valves are serviced. If the unloader remains

up, the suction valve is forced off its seat, and will

not seat and locate properly during reassembly.

To hold the unloader mechanism down, remove

the plug from the hole ‘B’ in the frame. Force the

unloader piston down and insert a short

5

/

16

”

(7.93 mm) diameter metal rod through the hole to

restrain the piston. Use a wooden block to force

the piston down to avoid scratching or damaging

the top of the unloader piston. Once the piston is

held down, the valve assemblies can be ser-

viced.

1. 440 Compressor (Mushroom Style)

(See Figure 7)

Lift out the safety head yoke, which holds

the safety head assembly in place. When

the yoke is out, lift out the safety head as-

sembly and suction valve plate.

To disassemble the safety head assembly,

remove the locknut on the valve retaining

screw.

1. 440 Compressor (Mushroom Style)

(cont’d)