VILTER MANUFACTURING CORPORATION

VILTER MultiCylinder Compressor

400 Series VMC 2/01

SERVICE - 23 - Replaces all Previous Issues

B. Reassembly (cont’d)

Connecting rod bolts are secured with one plain

steel nut and one spring steel locknut (commonly

referred to as a “Palnut”). The plain nut tighten-

ing torque should be listed in Table 2, 3 or 4 (de-

pending upon compressor model). The torque

wrenches should be set to the high side of the

tightening torque range.

As the rods, bearing inserts and crank pins are

all machine to fine tolerances, no further adjust-

ments are necessary.

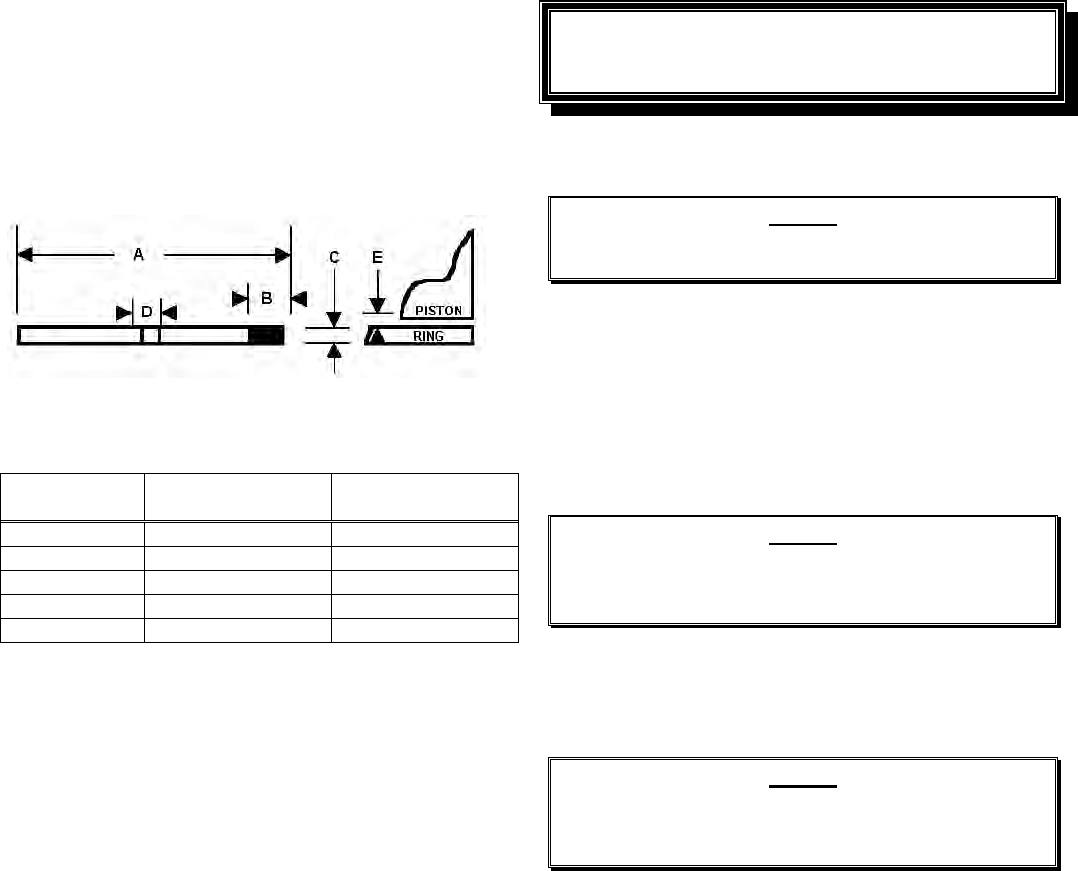

FIGURE 13. PISTON RING DIMENSIONS

TABLE 1. PISTON RING DIMENSIONS AND

TOLERANCES

DIMENSION COMPRESSION

RING

OIL RING

A 4.500 4.500

B 0.160 to 0.170 0.170 to 0.180

C 0.1230 to 0.1240 0.1860 to 0.1870

D 0.013 to 0.0225 0.013 to 0.023

E 0.002 to 0.004 0.0015 to 0.004

After a plain nut has been placed on a rod bolt

and torqued to the specified value, turn a Palnut

to the rod bolt with the open end of the hexagon

pointing away from the plain nut. The Palnut

should be turned until mating parts are pulled

together and actual tightening begins.

Final tightening and locking is then achieved by

giving the Palnut an additional 1/3 to 1/2 (maxi-

mum) turn. Although the plain steel nuts may be

reused, new unused Palnuts must be used each

time the connecting rods are reassembled to the

crankshaft. If used Palnuts are installed, their

locking feature is lost and a loose rod connection

may result. After each rod is installed, rotate the

crankshaft by hand to make sure everything is

free and there is no binding of the rotating parts.

CAUTION

Late model VMC compressors may push lin-

ers out.

XIII. CYLINDER LINERS

NOTE:

Before proceeding, refer to Paragraph I, “General

Service Instructions”.

A. Removal

Once the piston and rod assemblies are re-

moved, the liner can be extracted from the frame

by means of a Vilter Liner Pulling Tool (KT 257).

This tool, or similar, is required for all 440/450

compressors and 2-stage compressors.

NOTE:

If the cylinder bank has unloading, the unloader

piston needs to be held down for ease in liner

removal.

The liners in the 450XL compressor have a

looser fit into the frame. They can be removed

by pulling from the bottom of the liner by hand.

NOTE:

2-Stage liners have an extra groove without ring

that seals the suction chamber from the crank-

case.