Replaces R/S CK4A-2, CK4A-3, CK4A-4, CK4A-8, & CK4A-1.

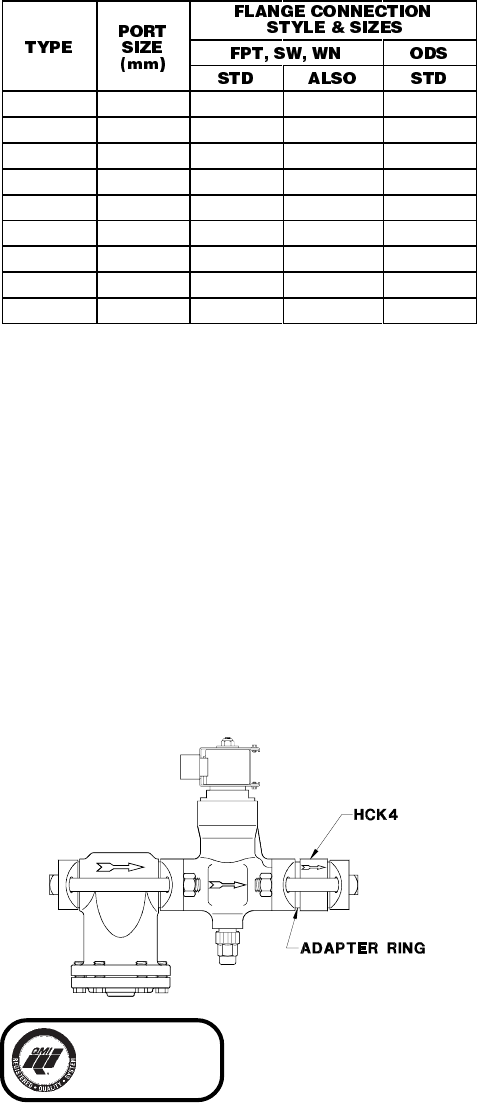

HCK4-2 close-couples to HS6 & HS8 Solenoid Valves.

HCK4-3, -4, & -5 close-couples to HS7 Solenoid Valve.

FPT available only

3

/8" to 1¼".

TO ORDER: Specify valve type, connection style and

size, and close-coupling information if needed.

TYPICAL SPECIFICATIONS

"Refrigeration in-line check valves shall have steel

or ductile iron bodies, stainless steel seat discs,

stainless steel closing springs, and be suitable for

a safe working pressure of 400 PSIG, as manufactured

by Hansen Technologies Corporation type HCK4 or

approved equal."

HCK4-2* (16) ½"

HCK4-3* ¾" (20) ¾" 1", 1¼"

HCK4-4* 1" (25) 1" ¾", 1¼"

HCK4-5 1¼" (32) 1¼" ¾", 1"

HCK4-7 1½" (40) 1½" 2"

HCK4-8* 2" (50) 2" 1½"

HCK4-9 2½" (65) 2½" 3"

HCK4-0 3" (80) 3" --

HCK4-1* 4" (100) 4" --

Printed in U.S.A.

HANSEN TECHNOLOGIES

CORPORATION

6827 High Grove Boulevard

Burr Ridge, Illinois 60527 U.S.A.

Telephone: (708) 325-1565 FAX: (708) 325-1572

Toll-free: 1-800-426-7368

OPERATION

HCK4 check valves are normally closed valves. As

inlet pressure increases, it overcomes the closing

spring force. As the seat disc is pushed back and

away from the seat cartridge, flow through the valve

occurs. The valve will remain open until the inlet

pressure drops below the closing spring force or

there is a flow reversal, at which time the seat disc

will close against the seat cartridge, preventing

reverse flow.

SIZING

Check valves are normally selected on the basis of

line size. However, for gas flow applications at low

load conditions, a minimum of 1 psid across the

valve is essential. This will maintain valve at full

open position. Valve Cv (Kv) is listed in the

installation dimension table on page 2. Factory valve

sizing assistance is available.

SERVICE AND MAINTENANCE

These valves are a reliable part of a refrigeration

system. However, if valve does not appear to be

operating satisfactorily, isolate it from the refrigeration

system. Remove all refrigerant from associated piping

and valves. Follow the guidelines in the caution

section. Loosen each flange nut on the check valve.

Break each flange gasket seal. Carefully loosen

flange bolts one at a time, being cautious to avoid

any refrigerant which still may be present. Remove

check valve from flanges and inspect. Lapped seating

surfaces should be smooth and free of pits or

scratches.

To confirm valve operation, move seat disc with

eraser end of pencil. Movement should be free from

friction. If not, disassemble and visually inspect for

dirt in valve or burrs on seat disc. Clean or replace

parts as necessary. Valve discs and seats can be

restored by lapping on a flat plate.

Reassemble valve and insert between flanges.

Replace and tighten bolts and nuts evenly. Carefully

check for leaks before returning to service.

CAUTION

Hansen check valves are only for refrigeration

systems. These instructions and related safety

precautions must be completely read and understood

before selecting, using, or servicing these valves.

Only knowledgeable, trained refrigeration mechanics

should install, operate, or service these valves. Stated

temperature and pressure limits should not be

exceeded. Valves should not be removed unless

system has been evacuated to zero pressure. See

also Safety Precautions in current List Price Bulletin

and Safety Precautions Sheet supplied with product.

Escaping refrigerant might cause personal injury,

particularly to the eyes and lungs.

WARRANTY

Hansen valves are guaranteed against defective

materials or workmanship for one year F.O.B. our

plant. No consequential damages or field labor is

included.

ORDERING INFORMATION,

HCK4 CHECK VALVES

*

Typical close-coupling to solenoid valve.

7

/8"

1

1

/8"

1

3

/8"

1

5

/8"

2

1

/8"

3

1

/8"

4

1

/8"

3

/8", ¾"

5

/8"

5

/8"

2

5

/8"

© 1995 Hansen Technologies Corporation

Hansen Technologies Corp.

Burr Ridge, IL Cert. # 000472

Orlando, FL Cert. # 001523

ISO 9002