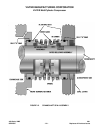

VILTER MANUFACTURING CORPORATION

VILTER MultiCylinder Compressor

400 Series VMC 2/01

SERVICE - 20 - Replaces all Previous Issues

A. Disassembly

After the cylinder covers, valves and handhole

cover have been removed, the first step in re-

moving the piston and rod assembly is to remove

the Palnut

®

locknuts on the rod bearing bolts.

Then, remove the plain nuts and slide the bear-

ing cap off of the nuts. The Palnut locknut is not

used with this type of locknut.

Handle the bearing cap carefully to avoid dam-

age to the bearing half insert. Push the rod and

piston out through the top of the cylinder. Avoid

possible mixing with components. Keep all parts

together in relation to their position in the com-

pressor. Connecting rods and rod caps are

match marked to aid in reassembly. On reas-

sembly, all parts must be installed in the same

position in the compressor.

As soon as the parts are removed from the com-

pressor, they should be thoroughly cleaned with

a suitable refrigeration parts cleaner. Once the

oil film is removed, the bare metal is subject to

rust. This reaction can start immediately. There-

fore, lubricate the surfaces of the parts lightly

with clean compressor oil immediately after

cleaning.

The tabs on the bearing half insert fit into the re-

cess in the rod and rod cap, and the inserts can

be slipped out without difficulty. To replace the

rod bearings, it is necessary to change the in-

serts only and not the entire rod.

1. 440 & 450 VMC Compressors Only

To remove the rod from the piston, take out

the piston pins. Remove the spring locks

from the pin hole on each side of the piston

and slide out the pins. If this cannot be ac-

complished by hand, it may be necessary to

force the pin out with a brass rod and ham-

mer. Be careful not to damage spring lock

grooves. To remove the piston rings, use

the ring expander. Caution should be exer-

cised to prevent the rings from scoring the

piston.

2. 450XL VMC Compressor Only

If the piston rings are to be removed, wrap a

piece of thin shim stock around the piston.

Work the rings carefully out of their grooves

and onto the shim stock. They can then be

worked down over the piston. Caution must

be exercised to prevent breaking the rings.

The piston and connecting rod assembly

should not be disassembled further. It is

furnished only as a complete assembly and

should not be worked on in the field.

B. Reassembly

All new compressors use three compression

rings and one oil control ring. When replacing

rings, use the ring expander. Check the grooves

to make sure they are clean.

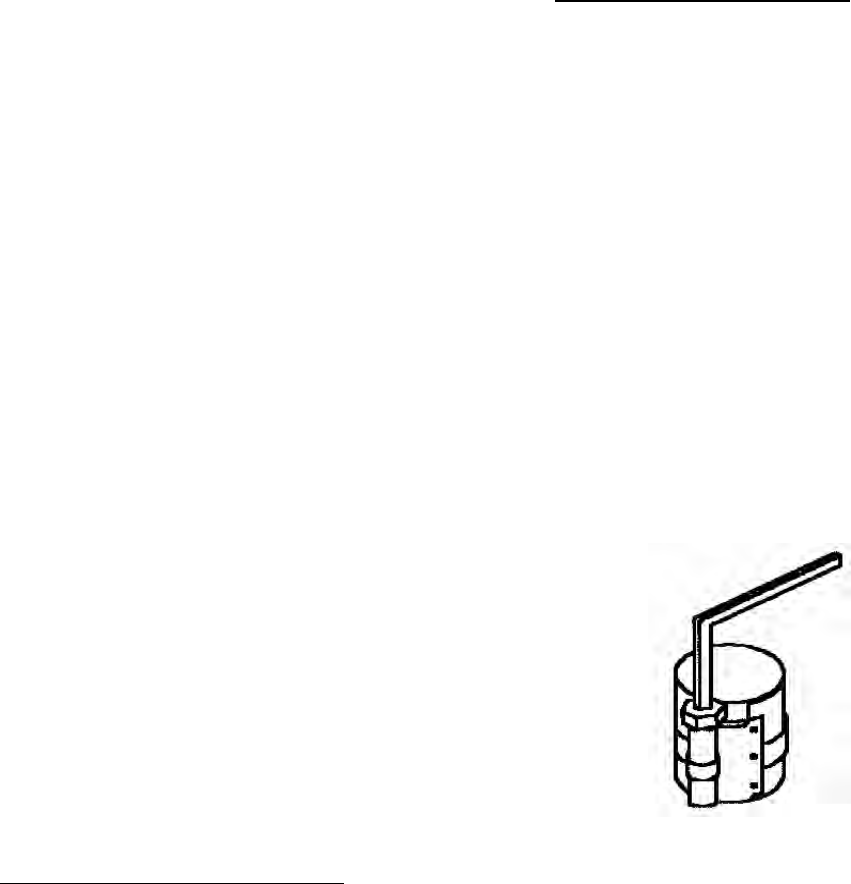

FIGURE 10. PISTON RING COMPRESSING

TOOL