SURE-GRIP BUSHING FEATURES

A1–2

Sure-Grip

®

“Quick Detachable” bushings are easy to install

and remove. They are split through flange and taper to provide a

true clamp on the shaft that is the equivalent of a shrink fit. All

sizes except JA and QT have a setscrew over the key to help

maintain the bushing’s position on the shaft until the cap screws

are securely tightened. Sure-Grip bushings have a very gradual

taper (3/4-inch taper per ft. on the diameter) which is about half

the inclined angle of many other bushings. The result is the

Sure-Grip securely clamps the shaft, with twice the force of

those competitive bushings, to provide extreme holding power.

Versatile Sure-Grip bushings permit the mounting of the same

mating part on shafts of different diameters, and the mounting

of different sheaves on the same shaft using the same bushing.

Their interchangeability extends through sheaves, pulleys,

timing pulleys, sprockets, flexible and rigid couplings, made-to-

order items by Wood’s, and to product lines of several other

mechanical power transmission manufacturers.

Sure-Grip bushings are manufactured with the drilled and

tapped holes located at a precise distance from the keyseat;

thus, a wide mating part having a bushing in each end can be

mounted on a common shaft with the two keyways in line. This

feature not only facilitates installation but also permits both

bushings to carry an equal share of the load.

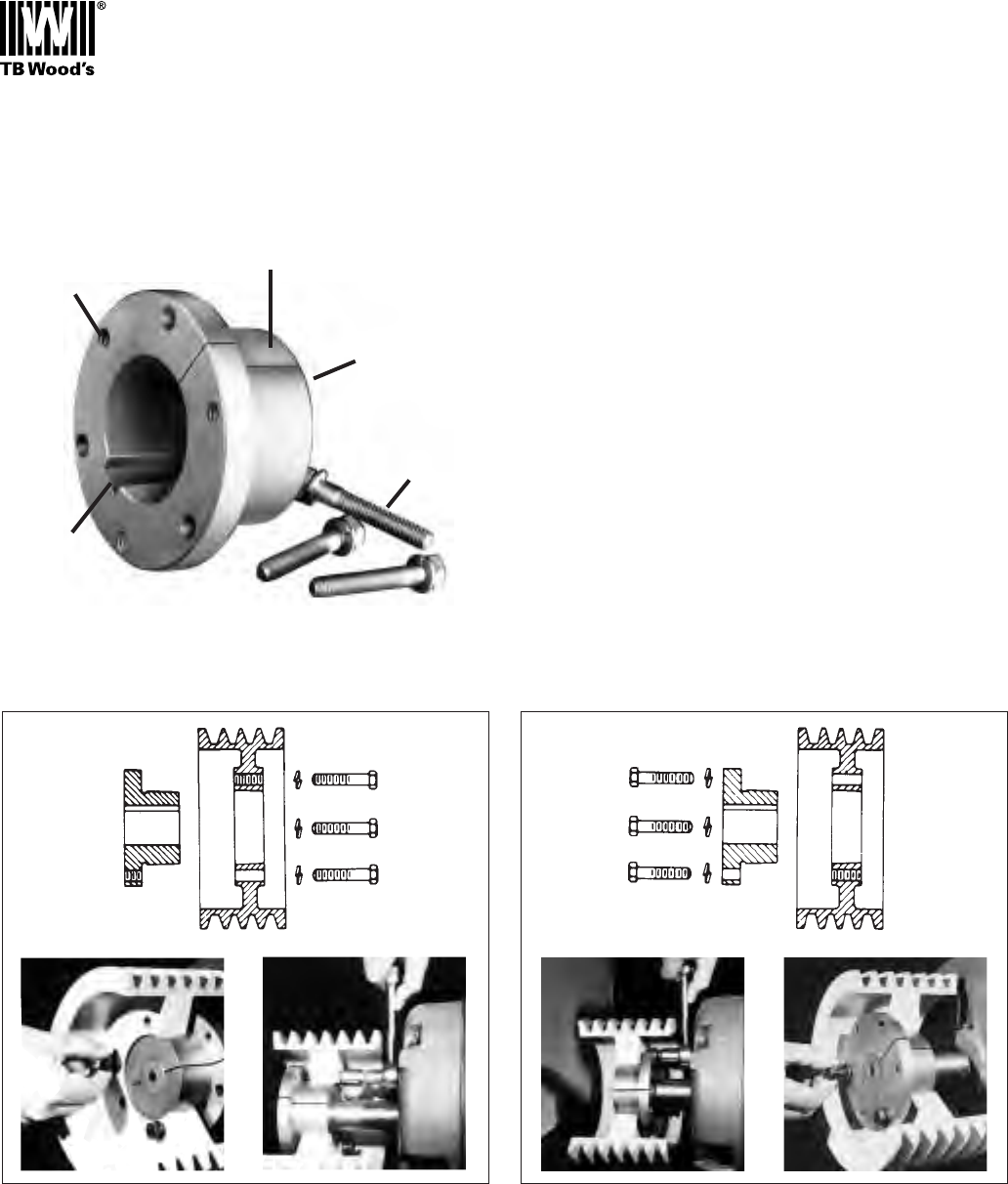

STANDARD MOUNTING REVERSE MOUNTING

1.

Cap screws from outside

through drilled holes in

the mating part and into

threaded holes in the

bushing flange located on

the inside of the assembly.

Or the complete assembly

reversed on the shaft and;

2. Cap screws from inside

through drilled holes in

the mating part and into

threaded holes in the

bushing flange located on

the outside of the assembly.

3. Cap screws from inside

through drilled holes in the

bushing flange located on

the inside of the assembly

and into threaded holes in

the mating part.

4. Cap screws from outside

through drilled holes in the

bushing flange located on

the outside of the assembly

and into threaded holes in

the mating part.

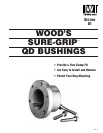

Cap screws used to

secure bushings to

sheave and to remove

bushing from sheave.

6-hole drilling (most sizes)

makes installation and

removal quick

and easy.

Keyseat 180°

from split.

Precise taper (3/4 in. per ft. on diameter)

provides proper wedging action.

Saw cut through flange and

taper (and sometimes cut

down into keyway also) to

provide a true clamp fit.