VILTER MANUFACTURING CORPORATION

VILTER MultiCylinder Compressor

400 Series VMC 2/01

SERVICE - 8 - Replaces all Previous Issues

2. Flywheel Removal (cont’d)

Screw the plate to the flywheel and tighten

the screws so the plate pulls tight against the

washers. Tighten the screws evenly so they

pull the flywheel. Apply pressure until the

flywheel breaks free.

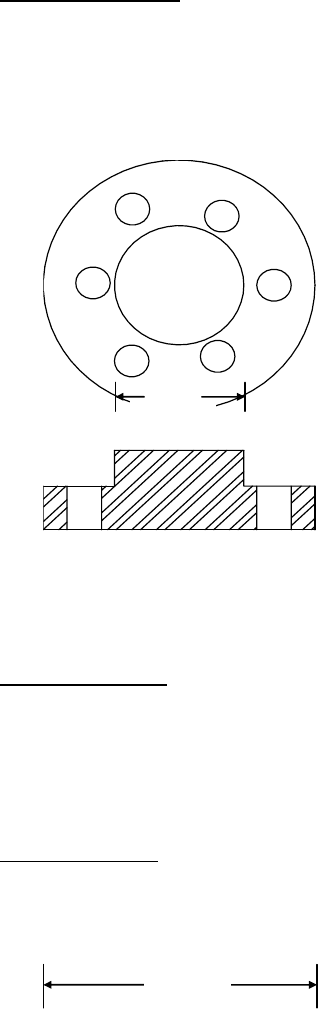

FIGURE 4. FLYWHEEL REMOVAL TOOL

3. Sheave Removal

Specific instructions for motor sheave main-

tenance are located after the Operation Sec-

tion of this manual. These should be con-

sulted for specific maintenance instructions.

4. Drive Inspection

Inspect the motor and compressor shafts,

sheave bushing and flywheel for fretting cor-

rosion or other wear. Fretting corrosion is

the result of two metallic surfaces (a shaft

and flywheel or bushing bore) having move-

ment relative to one another. This is usually

due to the incorrect tightening of drive com-

ponents, use of oil or other anti-seize com-

pounds, worn components, burrs or other

imperfections not allowing the flywheel and

crankshaft to mate properly.

Signs of fretting corrosion are reddish brown

powdery oxidation and wearing away of the

surface of the shafts or drive component

shaft bores. Minor fretting corrosion may be

eliminated through light sanding after which

the adequate contact area between the

crankshaft and flywheel must be assured to

prevent further fretting. Heavy fretting corro-

sion will require repair or replacement of the

motor shaft or replacement of the compres-

sor crankshaft and drive components. The

flywheel or crankshaft should not be re-

matched to eliminate the results of the fret-

ting corrosion, as adequate clearances can-

not be assured after remachining.

The drive keys should fit tightly in their re-

spective grooves and be free of damage.

The keyways should also be free of chips

and burrs that would not allow full contact of

the key to the keyway.

The flywheel and sheave should be in-

spected for abnormal wear and damage. A

groove wear gauge should be used to check

condition of the sidewalls and width of the

groove. Excessive wear is not permitted as

this will lead to problems in achieving correct

belt tension and loading, contributing to ex-

cessive belt and sheave wear.

Clean any foreign matter that has accumu-

lated in the grooves.

The sheave and pulley should be inspected

for cracks and other damage that could af-

fect the integrity of the drive components.

The sheave and pulley should be inspected

for excessive run-out, indicating bent com-

ponents. Bent pulleys or sheaves will wear

the groove sidewalls unevenly, as the belt

changes its angle of engagement as the pul-

ley turns.

5

”

Dia.

2

”

Dia.