VILTER MANUFACTURING CORPORATION

VILTER MultiCylinder Compressor

400 Series VMC 2/01

SERVICE - 24 - Replaces all Previous Issues

B. Lift Rings For Unloading

There are two styles of unloading lift ring assem-

blies.

1. 440 Lift Ring Assembly

Rotate the lift to align the notches with the

pins. The springs will follow. The lift ring will

then drop to the bottom of the liner.

Note the position of each lift pin. They will

have to be returned to that position for reas-

sembly. Push the lift pins up and out of the

top of the liner to remove them.

The assembly of the lift ring is the reverse

order of disassembly. Place the lift ring on a

flat surface with the notches facing up. Put

the liner in the center of the ring, and place a

spring on each roll pin in the ring.

Install a lift pin in each of the 4 slots along

the outside of the liner. The flat on the bot-

tom of the lift pin should be flush to the di-

ameter of the liner. Lift the ring up the liner,

and engage all four lift pin slots in the

notches on the ring. Rotate the ring so the

four springs engage in the holes of the lift

ring stop.

2. 450/450XL Lift Ring Assembly

Invert the liner and place on a flat surface.

Locate the notched end of the snap ring that

retains the lift ring, while pushing down on

the lift ring in this area. Pry the snap ring out

of its groove and continue all the way around

the liner.

Remove the snap ring, and slide the ring up

and off the liner. Now the 8 pins and springs

can be removed from the liner.

Reverse the procedure to install a lift ring

assembly on any 450/450XL liner.

B. Installation Of Liners

Before the liner is installed, make sure the outer

surface of the liner is clean and the seat area in

the frame is free of foreign matter. If a new o-

ring is required, lubricate the o-ring and frame

seating area with refrigeration oil. Slide the liner

into the frame and align with the bore. Roll pin

on the top of the liner can be orientated so if an

imaginary line is drawn to opposite pins, it forms

the letter “X”. Seat the liner in the frame recess

firmly by use of Vilter Cylinder Liner Tool (Vilter

Part No. 33464A). A similar tool can be con-

structed. Be sure to protect the liner lapped

seats to prevent damage.

FIGURE 14. CYLINDER LINER ASSEMBLY TOOL

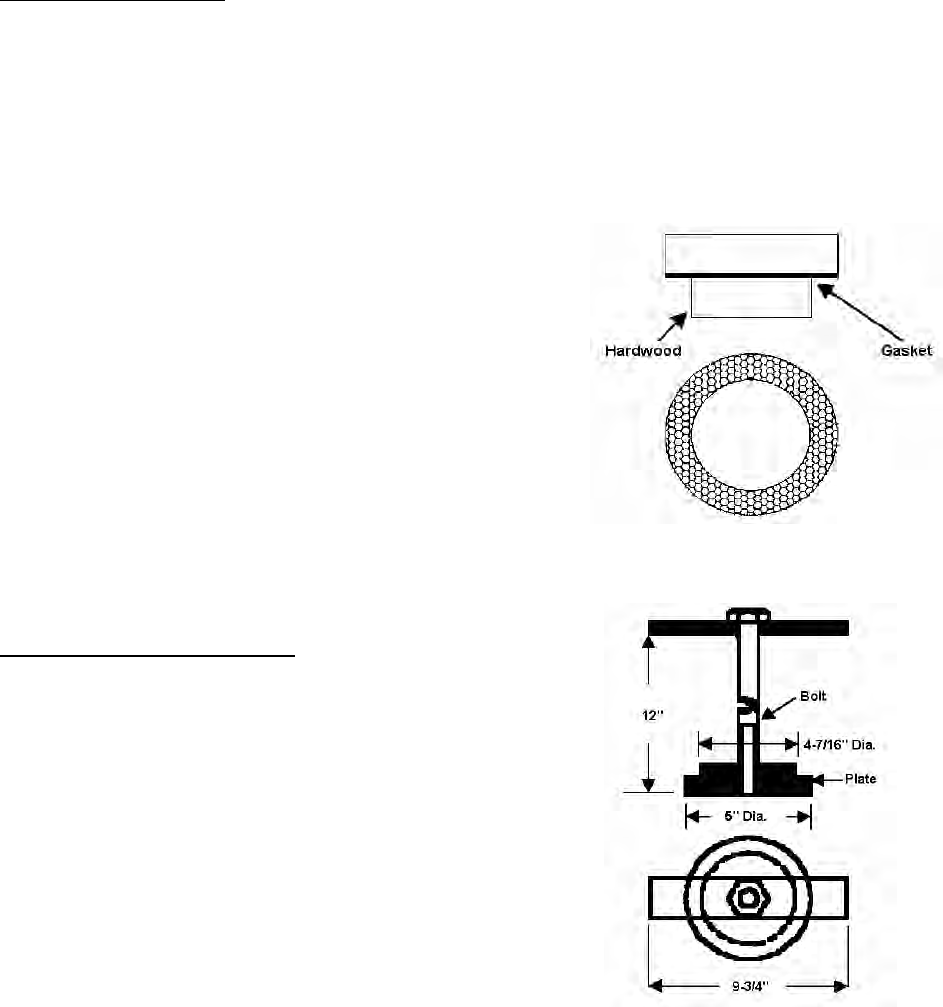

FIGURE 15. CYLINDER LINER REMOVAL TOOL

XIV. CRANKSHAFT