10 Technical data

Section 1: Introduction Operating and maintenance instructions

January 2015 3-9008-701 Rev J

Notes:

1. Consult the factory for optional voltages not listed.

2. The operating computer must be connected to a power source separate from that of

the prover to avoid variance in signal caused by line load charge and discharge.

3. Grounding wire within power cable must be connected to the installed location

electrical system grounding bus or electrical equivalent. A supplemental grounding

cable is available as an option.

4. For provers that are not equipped with a main circuit breaker, sizing of the main circuit

breaker should be based upon the hydraulic system motor full load amperage. Follow

applicable electrical codes for proper requirements.

Connection requirements:

Reference Table 1-2 for flange sizes

Pneumatic spring plenum:

Dry compressed nitrogen is required for charging the spring plenum.

Pressure drop: (Inlet flange to outlet flange)

Approximately 11.2 psig on gasoline at maximum flow (Metric units - .79 kg km ) Piston only:

Approximately 3 inches (7.6 cm) of water during a proving pass.

Approvals: For standard provers, sizes 8” thru 24” Canadian Standards Association (CSA) for

Class 1, Division 1, Group D File Number: LR 32408-18, Class 2258-02, Process Control

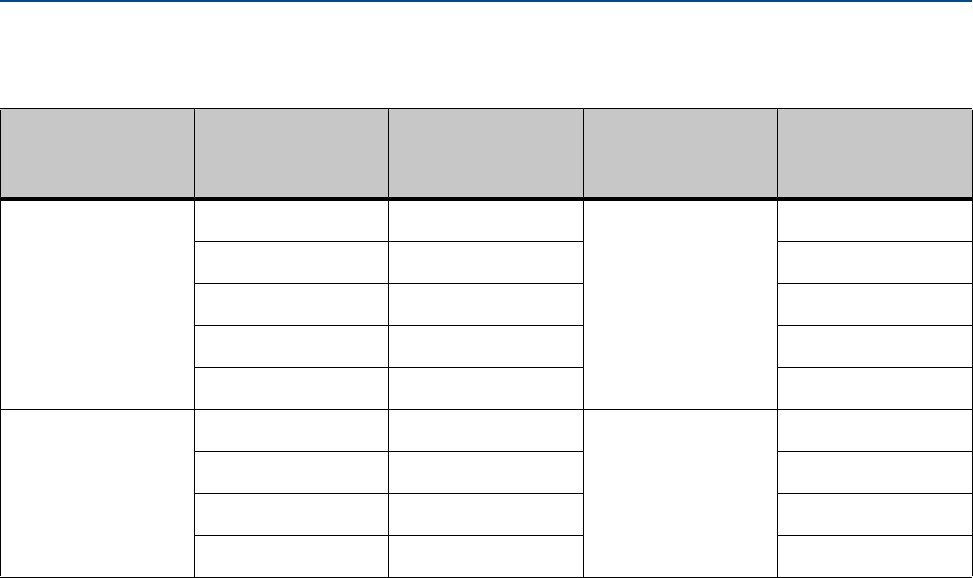

34”

230/60/3

39

15 Hp Single

.2

380/50/3

22

.2

415/50/3

20

.2

460/60/3

19.5

.2

690/50/3

12.8

.2

40”

230/60/3

50

20 Hp Single

.2

380/50/3

28

.2

415/50/3

26

.2

460/60/3

25

.2

Table 1-3 Power requirements

Size

AC line voltage,

frequency and

phase

Hydraulic system

motor full load

amps

Hydraulic system

motor

configuration

Hydraulic control

valve in-rush

amperage